A composite additive for strengthening the sintering of laterite nickel ore and its application method

A composite additive, a technology of laterite nickel ore, which is applied in the fields of metallurgy and material science, can solve the problems that restrict the development of laterite nickel ore sintering-blast furnace method, high energy consumption of sintered solids, and high crystallization water content, and can improve liquid phase fluidity, The effect of promoting microstructure formation and high FeO content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

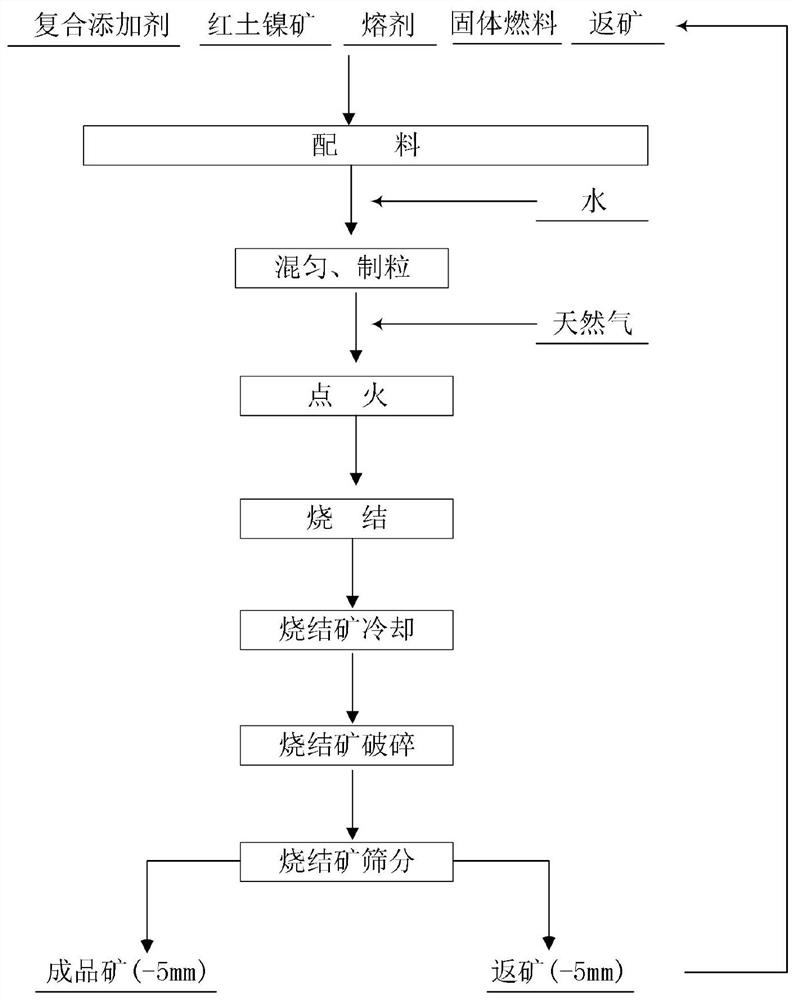

Method used

Image

Examples

Embodiment 1

[0044] (1) Batching: will contain the TFe of 48.48wt%, the Ni of 0.92wt%, the MgO of 1.36wt%, the SiO of 4.55wt% 2 The lateritic nickel ore with LOI value of 13.4wt%, with 5% composite additive (nickel smelting waste residue: 55%, magnetic separation tailings: 15%, waste activated carbon: 30%), 30wt% return ore, 5.5wt% pulverized coal , 6.5wt% unslaked lime; add water to the mixture, adjust the water content of the mixture to 17.0%; mix in a cylinder mixer, control the speed of the mixer to 30r min -1 , the filling rate was 25%, the digestion time was 3 minutes, and the granulation time was 4 minutes to obtain the sintered raw meal after granulation.

[0045] (2) Sintering: put the pellets into the sintering cup, add sintered ore with a particle size of 10-16mm to lay the bottom material before cloth, and then put the pellets evenly into the sintering cup, the cloth height is 800mm, Then lightly press it to 780mm with a presser. The sintering ignition adopts natural gas igni...

Embodiment 2

[0049] (1) Batching: will contain the TFe of 48.48wt%, the Ni of 0.92wt%, the MgO of 1.36wt%, the SiO of 4.55wt% 2 The lateritic nickel ore with LOI value of 13.4wt%, with 10% composite additive (nickel smelting waste residue: 65%, magnetic separation tailings: 10%, waste activated carbon: 25%), 30wt% return ore, 4.5wt% pulverized coal , 6.5wt% unslaked lime; add water to the mixture, adjust the water content of the mixture to 16.7%; mix in a cylinder mixer, control the speed of the mixer to 30r min -1 , the filling rate was 25%, the digestion time was 3 minutes, and the granulation time was 5 minutes to obtain the sintered raw meal after granulation.

[0050] (2) Sintering: put the pellets into the sintering cup, add sintered ore with a particle size of 10-16mm to lay the bottom material before cloth, and then put the pellets evenly into the sintering cup, the cloth height is 800mm, Then lightly press it to 780mm with a presser. The sintering ignition adopts natural gas ign...

Embodiment 3

[0054] (1) Batching: will contain the TFe of 48.48wt%, the Ni of 0.92wt%, the MgO of 1.36wt%, the SiO of 4.55wt% 2 The lateritic nickel ore with LOI value of 13.4wt%, with 15% composite additive (nickel smelting waste residue: 60%, magnetic separation tailings: 15%, waste activated carbon: 25%), 30wt% return ore, 3.2wt% pulverized coal , 6.8wt% unslaked lime and mix; add water in the mixture, adjust the water content of the mixture to be 16.7%; mix in the cylinder mixer, control the speed of the mixer to 30r min -1 , the filling rate was 25%, the digestion time was 3 minutes, and the granulation time was 4 minutes to obtain the sintered raw meal after granulation.

[0055] (2) Sintering: put the pellets into the sintering cup, add sintered ore with a particle size of 10-16mm to lay the bottom material before cloth, and then put the pellets evenly into the sintering cup, the cloth height is 950mm, Then lightly press it to 930mm with a presser. The sintering ignition adopts na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com