Preparation method of ternary nickel-cobalt-manganese sulfide pseudocapacitance supercapacitor material

A supercapacitor, nickel-cobalt-manganese technology, applied in the field of preparation of ternary nickel-cobalt-manganese sulfide pseudocapacitive supercapacitor materials, can solve the problems of increasing the uncontrollable factors of the reaction process, the influence of the physical chemistry and electrochemical performance of the synthetic material, etc. Achieve the effect of reducing uncontrollable factors, efficient application and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

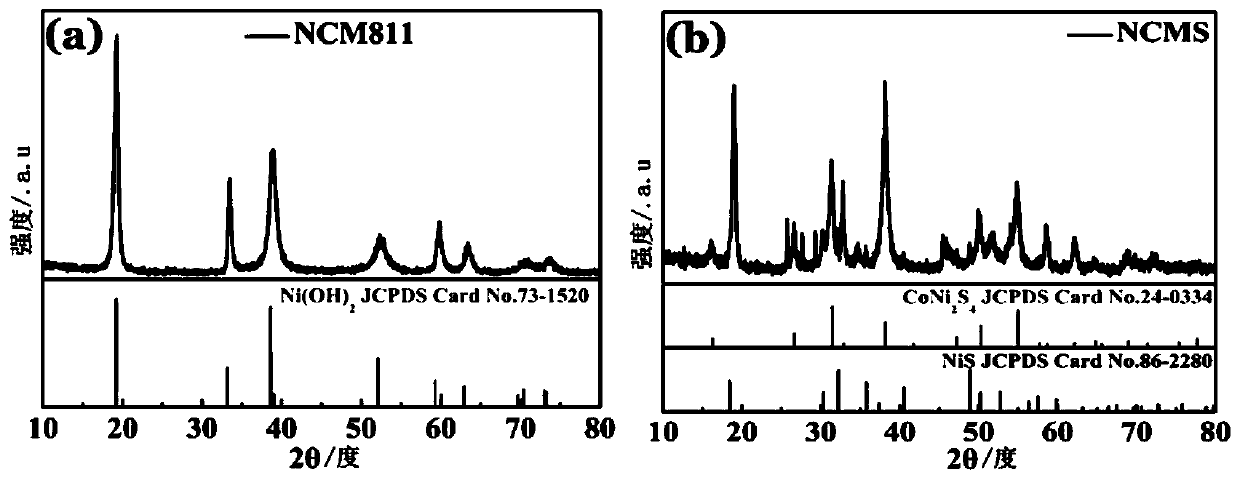

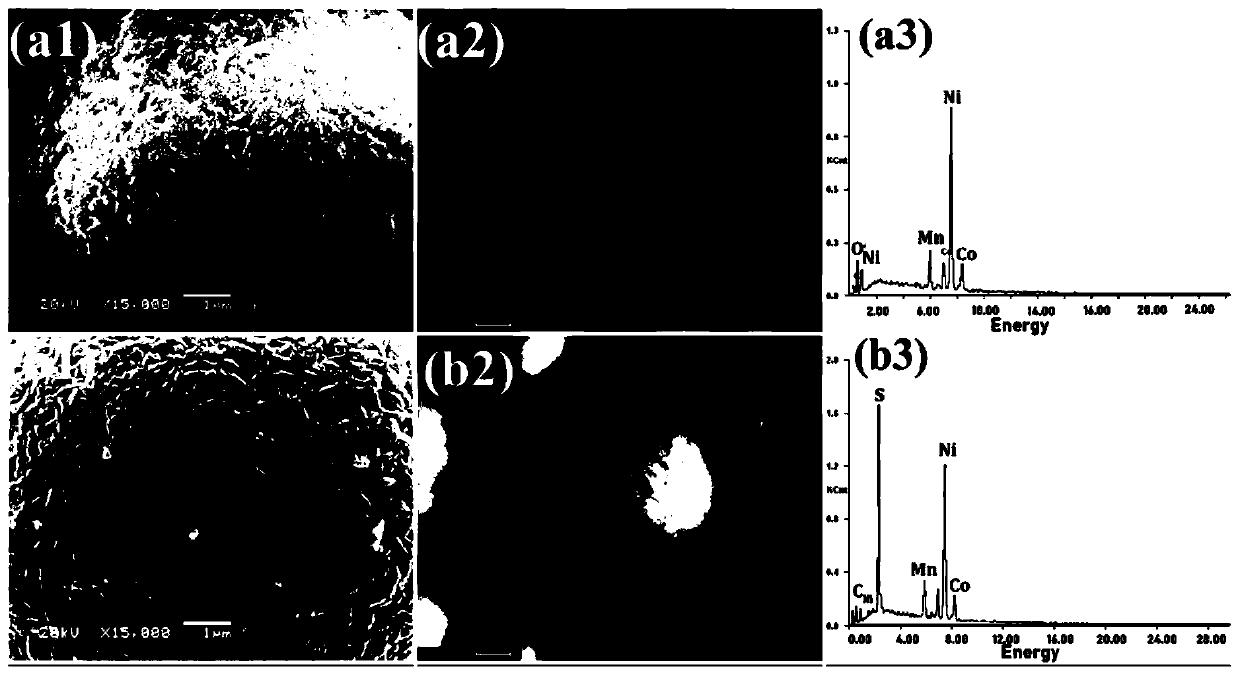

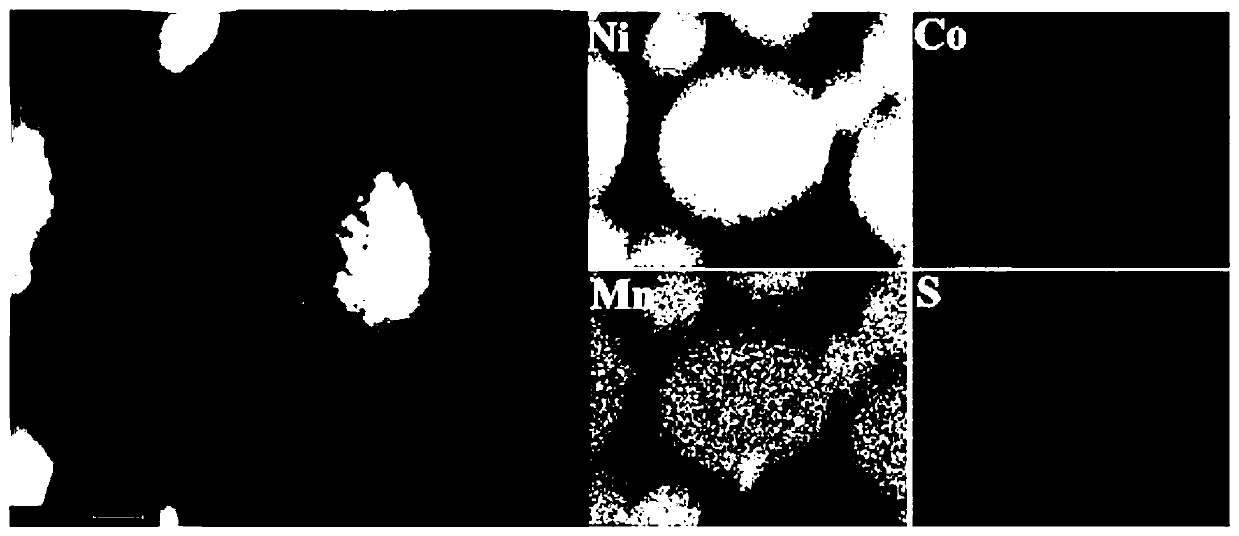

[0032] A preparation method of a ternary nickel-cobalt-manganese sulfide pseudocapacitive supercapacitor material of the present invention, comprising the following steps:

[0033] (1) Weigh 0.2g of Ni prepared by coprecipitation method 0.8 co 0.1 mn 0.1 (OH) 2 (NCM811) precursor was placed in 100mL deionized water, and magnetically stirred for 30 minutes to obtain a uniformly dispersed suspension;

[0034] (2) Weigh 1.7156g sodium sulfide nonahydrate (Na 2 S·9H 2 O) Add to the above suspension, continue magnetic stirring for 30min to mix the two raw materials evenly, then transfer the mixed solution into a 200mL polytetrafluoroethylene reactor, keep it warm at 180°C for 8h, turn off the power of the oven, and make the reactor Take out after cooling to room temperature with the furnace;

[0035] (3) Suction and wash the reaction product obtained in step (2) with deionized water, place the obtained filter cake in a petri dish, add a small amount of deionized water for ult...

Embodiment 2

[0043] A preparation method of a ternary transition metal sulfide pseudocapacitive supercapacitor electrode material, comprising the following steps:

[0044] (1) Weigh 0.2g of Ni prepared by coprecipitation method 0.6 co 0.2 mn 0.2 (OH) 2 (NCM622 precursor) was placed in 100mL deionized water, and magnetically stirred for 30min to obtain a uniformly dispersed suspension;

[0045] (2) Weigh 1.7156g sodium sulfide nonahydrate (Na 2 S·9H 2 O) Add to the above suspension, continue magnetic stirring for 30 minutes to mix the two raw materials evenly, then transfer the mixed solution into a 200mL polytetrafluoroethylene reactor, keep it warm at 180°C for 10h, turn off the power of the oven, and make the reactor Take out after cooling to room temperature with the furnace;

[0046] (3) Use deionized water to filter and wash the reaction product, place the obtained filter cake in a petri dish, add a small amount of deionized water to ultrasonically disperse for 5 minutes to obta...

Embodiment 3

[0048] A preparation method of a ternary transition metal sulfide pseudocapacitive supercapacitor electrode material, comprising the following steps:

[0049] (1) Weigh 0.2 g of the NCM811 precursor prepared by the co-precipitation method, place it in 100 mL of deionized water, and stir it magnetically for 30 minutes to obtain a uniformly dispersed suspension;

[0050] (2) Weigh 0.5367g thioacetamide (CH 3 CSNH 2 ) into the above suspension, continue magnetic stirring for 30 minutes to mix the two raw materials evenly, then transfer the mixture into a 200mL polytetrafluoroethylene reactor, keep it warm at 180°C for 8 hours, turn off the power of the oven, and let the reactor Take out after cooling to room temperature;

[0051] (3) Use deionized water to filter and wash the reaction product, place the obtained filter cake in a petri dish, add a small amount of deionized water to ultrasonically disperse for 5 minutes to obtain a uniform suspension, put it in the freezer for pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com