A kind of molten salt method prepares the method for metal oxide or metal hydroxide nano film material

A nano-film material, hydroxide technology, applied in the directions of nickel oxide/nickel hydroxide, manganese oxide/manganese hydroxide, copper oxide/copper hydroxide, etc., can solve the problems of long time, high temperature, and many steps, etc. To achieve the effect of enhancing fluidity, simple preparation method and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

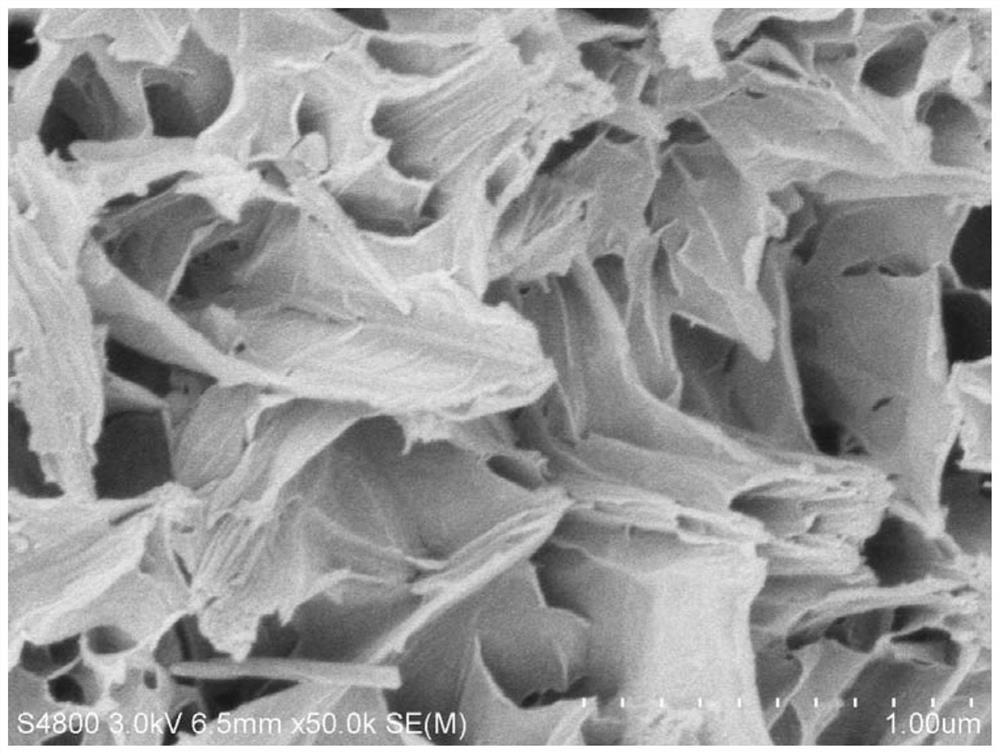

[0035] (1) Select size 4×2cm 2 The foamed nickel as the substrate, the substrate is removed with 10% hydrochloric acid, and the substrate is ultrasonically washed with deionized water, and dried completely in vacuum for use; (2) Melt 10g of sodium nitrate at 350°C; (3) Melt the sodium nitrate completely Then add foamed nickel to react for 1 minute; (4) add 0.1g of manganese sulfate to the reaction system of foamed nickel and sodium nitrate, keep the system temperature unchanged, and continue to react for 1 minute; (5) add the oxidation obtained in step (4) The manganese / nickel foam nano film is taken out and cooled to room temperature, and ultrasonically cleaned with deionized water; (6) the cleaned product is completely dried to obtain a manganese oxide / nickel foam nano film material. The field emission scanning electron microscope photograph of the obtained nano film material is as follows figure 1 As shown, the observation results of the surface morphology show that the surfa...

Embodiment 2

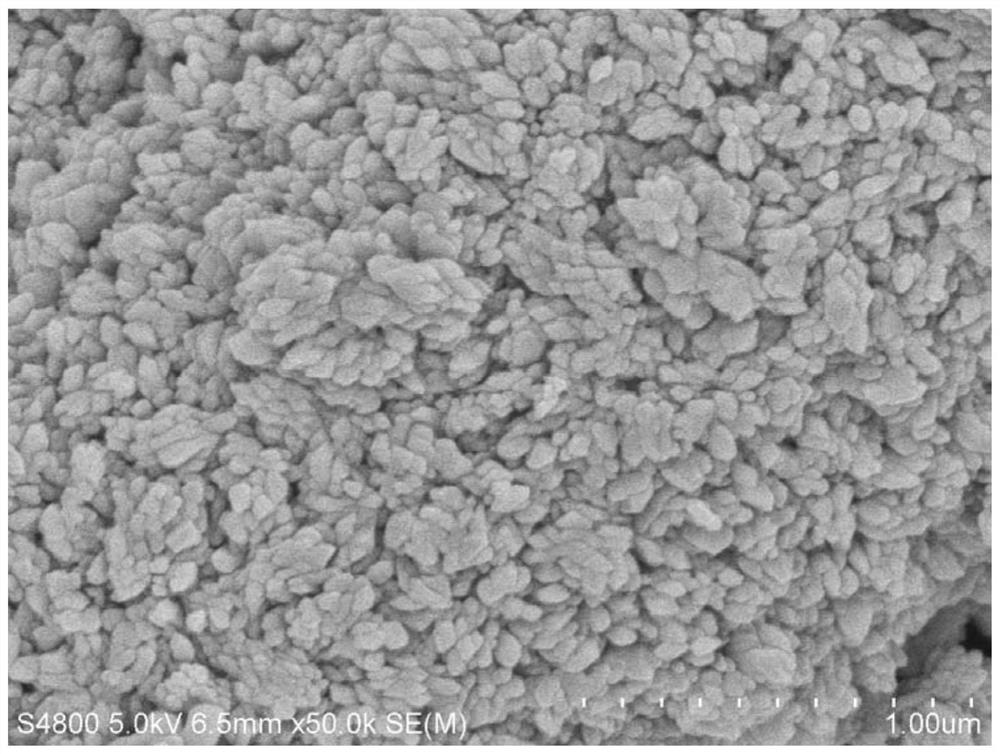

[0037] (1) Select size 4×2cm 2 The carbon cloth is the substrate, and the substrate is ultrasonically washed with deionized water and dried for later use; (2) Melt 4.3 g of potassium nitrate at 380°C; (3) After the potassium nitrate is completely melted, add the carbon fiber cloth to react for 2 minutes; 4) Add 2.9g of copper chloride to the reaction system of carbon cloth and potassium nitrate, raise the temperature by 10°C, and react for 30 seconds; (5) Take out the copper oxide / carbon fiber cloth nano film obtained in step (4) and cool it To room temperature, and ultrasonically clean with deionized water; (6) completely dry the cleaned product to obtain a copper oxide / carbon cloth nano-film material. The field emission scanning electron microscope photograph of the obtained nano film material is as follows figure 2 As shown, the observation results of the surface morphology show that the surface of the film is nanoparticles that grow head-to-tail, and the nanostructure layer...

Embodiment 3

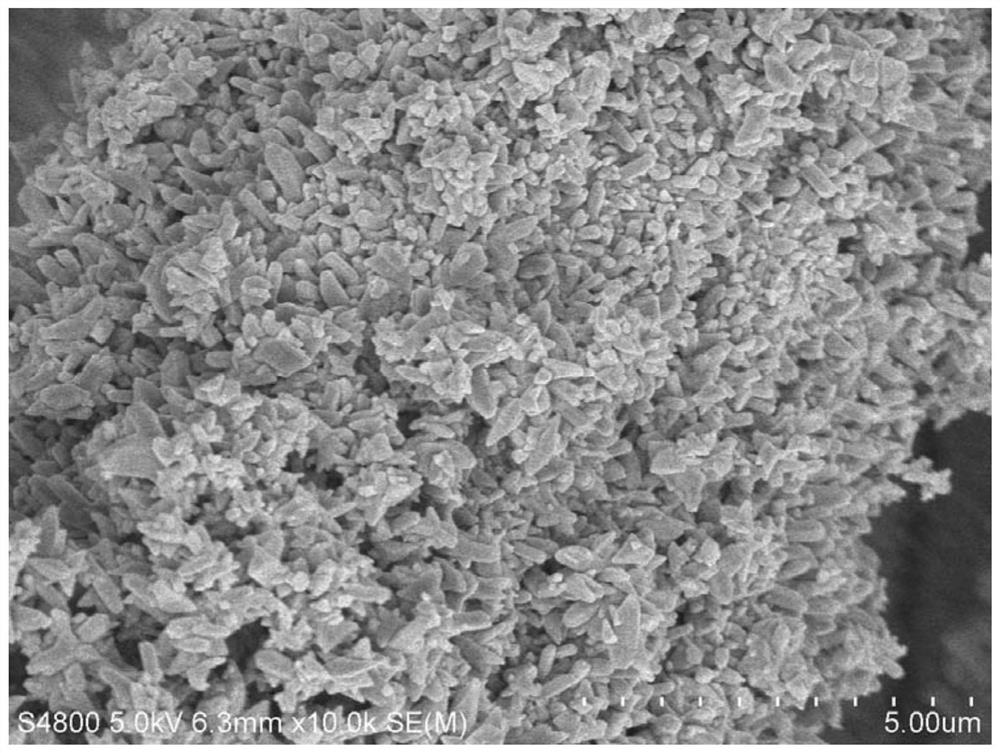

[0039] (1) Select size 4×2cm 2 The carbon cloth is the substrate, and the substrate is ultrasonically washed with deionized water and dried for later use; (2) Melt 2.6 g of potassium nitrate at 380°C; (3) After the potassium nitrate is completely melted, add the carbon fiber cloth to react for 10 minutes; 4) Add 0.17g of copper nitrate to the reaction system of carbon cloth and potassium nitrate, keep the temperature of the system unchanged, and continue to react for 10 seconds; (5) Take out the copper oxide / carbon fiber cloth nano film obtained in step (4) and cool it To room temperature, and ultrasonically clean with deionized water; (6) completely dry the cleaned product to obtain a copper oxide / carbon cloth nano cloth film material. The field emission scanning electron microscope photograph of the obtained nano film material is as follows image 3 As shown, the observation result of the surface morphology shows that the surface of the film is uniformly distributed nanorods, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com