Lithium iron phosphate composite positive electrode material and its preparation method and application

A composite cathode material, lithium iron phosphate technology, applied in the field of lithium ion batteries, can solve the problems affecting the rate performance of lithium iron phosphate materials, poor conductivity of lithium ion diffusion, poor lithium ion diffusion ability, etc., to avoid equipment and Huge energy consumption, avoiding enrichment or segregation, and improving the effect of diffusion capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

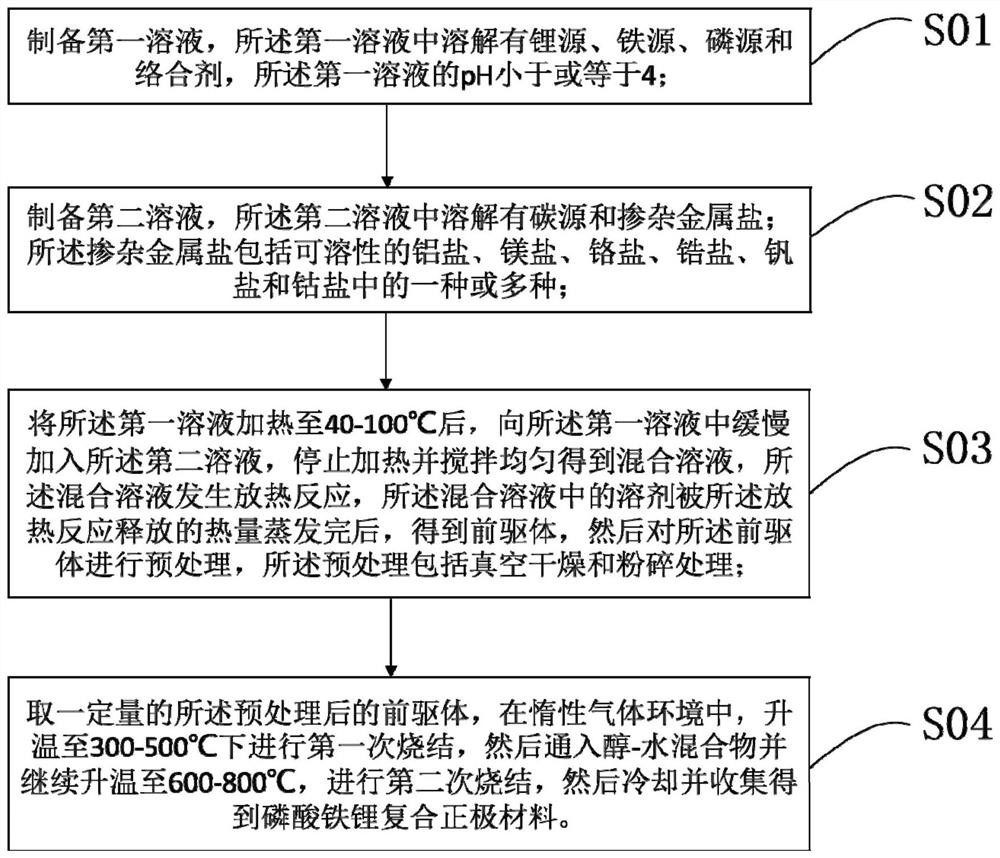

[0070] Such as figure 1 As described above, in one embodiment of the present invention, a method for preparing a lithium iron phosphate composite positive electrode material is provided, comprising the following steps:

[0071] S01, preparing a first solution, in which a lithium source, an iron source, a phosphorus source and a complexing agent are dissolved, and the pH of the first solution is less than or equal to 4;

[0072] S02, preparing a second solution, in which a carbon source and a doping metal salt are dissolved; the doping metal salt includes soluble aluminum salts, magnesium salts, chromium salts, zirconium salts, vanadium salts and cobalt salts one or more of

[0073] S03, after heating the first solution to 40-100°C, slowly add the second solution into the first solution, stop heating and stir evenly to obtain a mixed solution, the mixed solution undergoes an exothermic reaction, the After the solvent in the mixed solution is evaporated by the heat released by...

Embodiment 1

[0078] A preparation method of lithium iron phosphate composite cathode material, comprising the following steps:

[0079] (1) Add lithium carbonate, iron nitrate and ammonium dihydrogen phosphate in a molar ratio of 1:1:1 to the nitric acid solution, and add a citric acid complexing agent to adjust the pH to 3 to prepare the first solution.

[0080] (2) take by weighing about 0.5% soluble ammonium metavanadate, cobalt nitrate etc. of mole percentage and enter into deionized water for dissolving, then add the carbon source that glucose and fructose form, wherein, the quality of carbon source accounts for lithium carbonate, 25% of the total mass of ferric nitrate and ammonium dihydrogen phosphate is fully stirred to form a second solution; the molar ratio of ammonium metavanadate to cobalt nitrate is 2:1; the volume ratio of the second solution to the first solution It is 1:3.

[0081] (3) Turn on the heating, heat the first solution to 80°C, slowly pour the second solution into...

Embodiment 2

[0085] A preparation method of lithium iron phosphate composite cathode material, comprising the following steps:

[0086] Same as Example 1, except that the molar percentage of doped metal salt is brought up to 2%, except that, other steps are all the same as Example 1, specifically comprising:

[0087] (1) Add lithium carbonate, iron nitrate and ammonium dihydrogen phosphate in a molar ratio of 1:1:1 to the nitric acid solution, and add a citric acid complexing agent to adjust the pH to 3 to prepare the first solution.

[0088] (2) take by weighing about 2% soluble ammonium metavanadate, cobalt nitrate etc. of molar percentage and enter into deionized water and dissolve, then add the carbon source that glucose and fructose form, wherein, the quality of carbon source accounts for lithium carbonate, 25% of the total mass of ferric nitrate and ammonium dihydrogen phosphate is fully stirred to form a second solution; the molar ratio of ammonium metavanadate to cobalt nitrate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com