Ceramic reinforced steel-based wear-resisting composite and preparation method thereof

A technology of composite materials and ceramics, applied in the field of wear-resistant composite materials, can solve problems such as performance improvement, achieve good impact resistance and wear resistance, avoid overall shedding, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

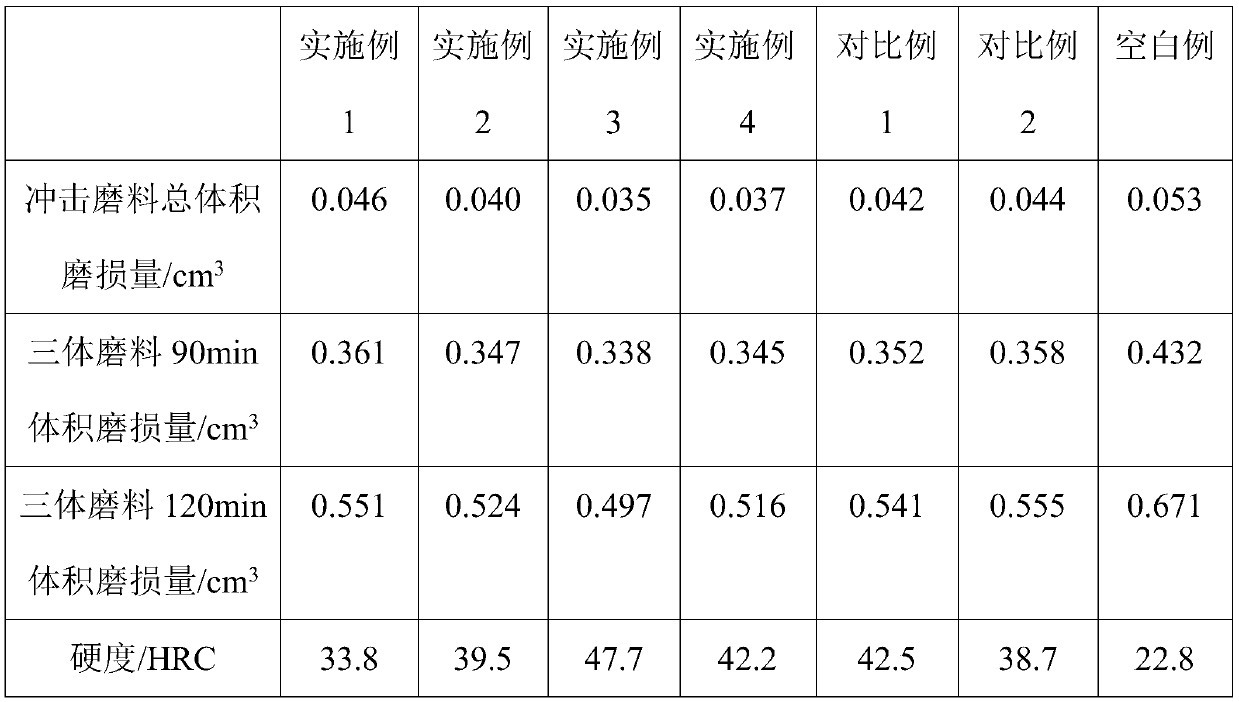

Examples

Embodiment 1

[0022] A ceramic-reinforced steel-based wear-resistant composite material proposed by the present invention is prepared by casting alloy steel metal liquid and casting and infiltrating ceramic prefabricated body by casting infiltration method;

[0023] Among them, the alloy steel is ZGMn13Cr2 high manganese steel;

[0024] The ceramic prefabricated body is made up of the raw material of following percentage by weight: spherical ceramic particle 55wt%, non-spherical polyhedron ceramic particle 40wt%, binder 5wt%; Wherein, spherical ceramic particle is spherical WC ceramic particle, particle size is 0.5mm; non-spherical polyhedron The ceramic particles are polyhedral alumina ceramic particles with a particle size of 0.8mm; the binder is an epoxy resin binder or a phenolic liquid resin binder; the volume fraction of the ceramic particles in the ceramic preform in the composite material is 18vt%;

[0025] The present invention also proposes a method for preparing the ceramic-reinf...

Embodiment 2

[0030] A ceramic-reinforced steel-based wear-resistant composite material proposed by the present invention is prepared by casting alloy steel metal liquid and casting and infiltrating ceramic prefabricated body by casting infiltration method;

[0031] Among them, the alloy steel is ZGMn13Cr2 high manganese steel;

[0032] The ceramic prefabricated body is made up of the raw material of following percentage by weight: spherical ceramic particle 49wt%, non-spherical polyhedral ceramic particle 49wt%, binding agent 2wt%; Wherein, spherical ceramic particle is spherical ZTA ceramic particle, particle size is 0.7mm; non-spherical polyhedral The ceramic particles are polyhedral WC ceramic particles with a particle size of 1.5mm; the binder is an epoxy resin binder or a phenolic liquid resin binder; the volume fraction of the ceramic particles in the ceramic preform in the composite material is 20vt%;

[0033] The present invention also proposes a method for preparing the ceramic-re...

Embodiment 3

[0038] A ceramic-reinforced steel-based wear-resistant composite material proposed by the present invention is prepared by casting alloy steel metal liquid and casting and infiltrating ceramic prefabricated body by casting infiltration method;

[0039] Among them, the alloy steel is ZGMn13Cr2 high manganese steel;

[0040] The ceramic prefabricated body is made up of the raw material of following percentage by weight: spherical ceramic particle 46wt%, non-spherical polyhedral ceramic particle 50wt%, binding agent 4wt%; Wherein, spherical ceramic particle is spherical ZTA ceramic particle, particle size is 0.6mm; non-spherical polyhedral The ceramic particles are polyhedral alumina ceramic particles with a particle size of 1.3mm; the binder is an epoxy resin binder or a phenolic liquid resin binder; the volume fraction of the ceramic particles in the ceramic preform in the composite material is 23vt%;

[0041] The present invention also proposes a method for preparing the ceram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com