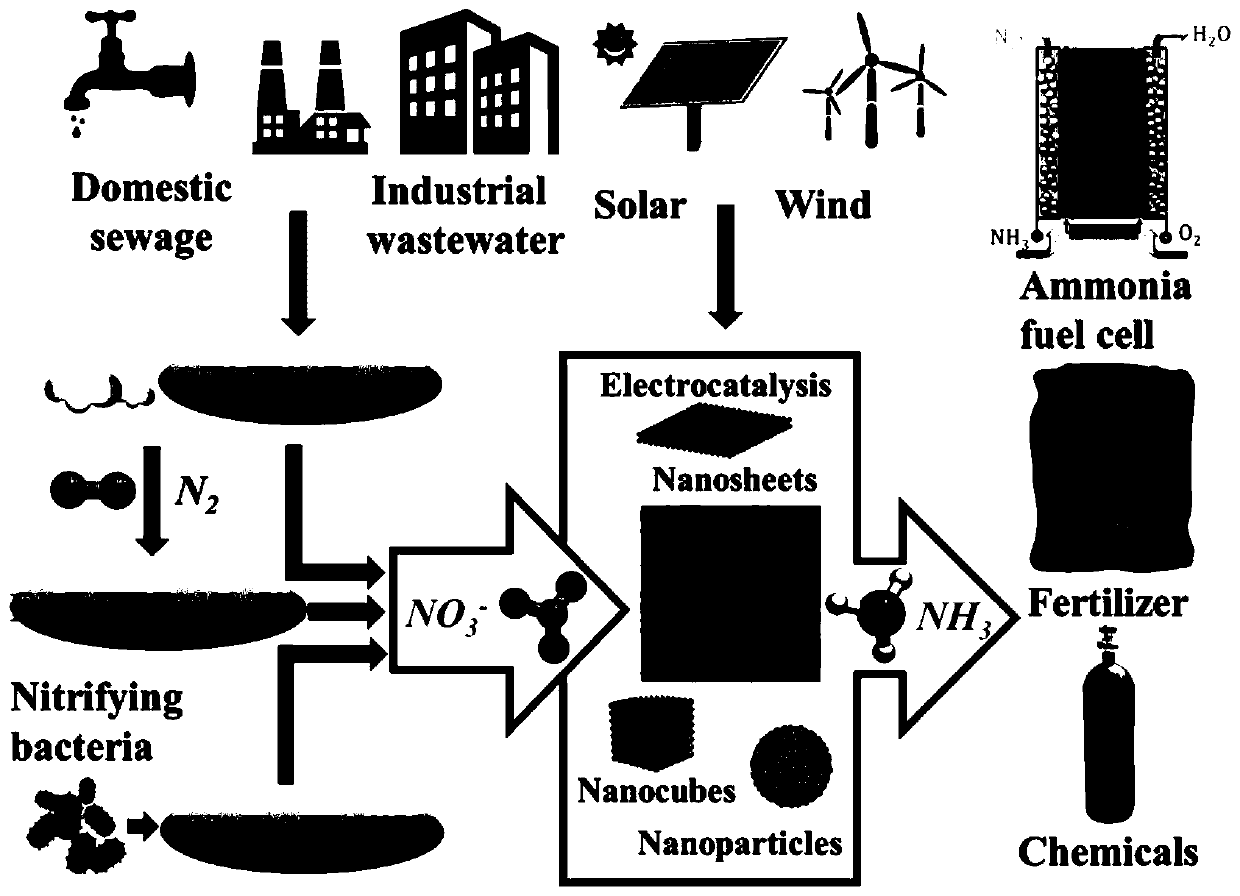

Nano-copper catalyst, preparation method thereof and application to synthesis of acetic acid or ammonia

A catalyst, nano-copper technology, applied in nano-copper catalyst and its preparation, application field in synthesizing acetic acid or ammonia, can solve the problems of low ammonia production rate and current efficiency, limited application, etc., achieve clear structure, efficiency and selectivity High and regular appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

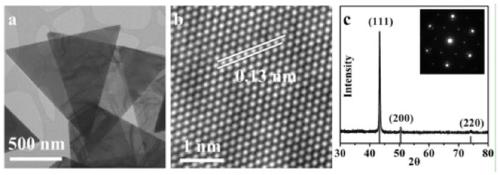

[0026] A kind of nano-copper catalyst, this catalyst comprises carbon paper substrate and the copper nano sheet that is loaded on carbon paper, and the loading capacity of copper nano sheet on carbon paper is 1.0mg / cm 2 about. The catalyst is prepared by the following method:

[0027] (1) Synthesis of copper nanosheets: Dissolve copper nitrate, ascorbic acid, hexamethylenetetramine and cetyltrimethylammonium bromide in deionized water at a molar ratio of 1:0.1:0.5:0.5, and stir to form Homogeneous solution, the solution is placed in an oil bath at 100°C for 2 hours, and after cooling, a mixture of ethanol and water is added for washing and centrifugation, and the precipitate is taken and dried to obtain an active agent, which is copper nanosheets;

[0028] (2) Clean copper nanosheets: prepare cleaning agent with ethanol and deionized water, and the volume ratio of ethanol and deionized water in the prepared cleaning agent is 1:9; 4 Hz frequency ultrasonic cleaning for 8min, ...

Embodiment 2

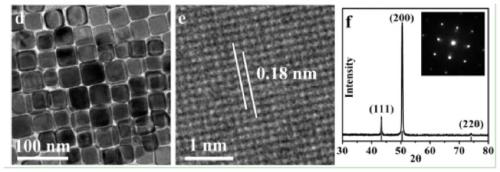

[0032] A nano-copper catalyst comprising a carbon cloth substrate and copper nanocubes loaded on the carbon cloth, the loading of the copper nanocubes on the carbon paper is 3.0 mg / cm 2 about. The catalyst is prepared by the following method:

[0033] (1) Clean copper nano cube: prepare cleaning agent with ethanol and deionized water, the volume ratio of ethanol and deionized water in the prepared cleaning agent is 1:1; Then the copper nano cube that will make is immersed in the cleaning agent, Take 8×10 4 Hz frequency ultrasonic cleaning for 5min, then dry for later use;

[0034] (2) Preparation of slurry: Add Nafion conductive binder with a concentration of 10% to the cleaned active agent, the mass ratio of Nafion to active agent is 1:1, then add appropriate amount of ethanol, fully stir and disperse After obtaining the slurry;

[0035] (3) Catalyst preparation: the slurry was uniformly coated on the surface of carbon paper and dried with nitrogen flow to obtain a cataly...

Embodiment 3

[0037] A kind of nano-copper catalyst, this catalyst comprises carbon paper substrate and the copper nanowire that is loaded on carbon paper, and the loading capacity of copper nanowire on carbon paper is 0.5mg / cm 2 about. The catalyst is prepared by the following method:

[0038] (2) Clean copper nanowires: prepare cleaning agent with ethanol and deionized water, the volume ratio of ethanol and deionized water in the prepared cleaning agent is 4:1; Then the copper nanowires prepared are immersed in the cleaning agent, to 4×10 4 Hz frequency ultrasonic cleaning for 10min, then dry for later use;

[0039] (3) Preparation of slurry: Add Nafion conductive binder with a concentration of 10% to the cleaned active agent, the mass ratio of Nafion to active agent is 1:4, then add appropriate amount of ethanol, fully stir and disperse After obtaining the slurry;

[0040] (4) Catalyst preparation: the slurry was uniformly coated on the surface of carbon paper and dried with nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com