Temperature control-based high-energy storage flexible composite membrane and preparation method thereof

A composite film and high energy storage technology, which is applied to the parts of fixed capacitors and the dielectric of fixed capacitors, etc., can solve the problems of poor conductivity and increase energy storage density, and achieve increased dielectric constant, avoid aggregation, and simple process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

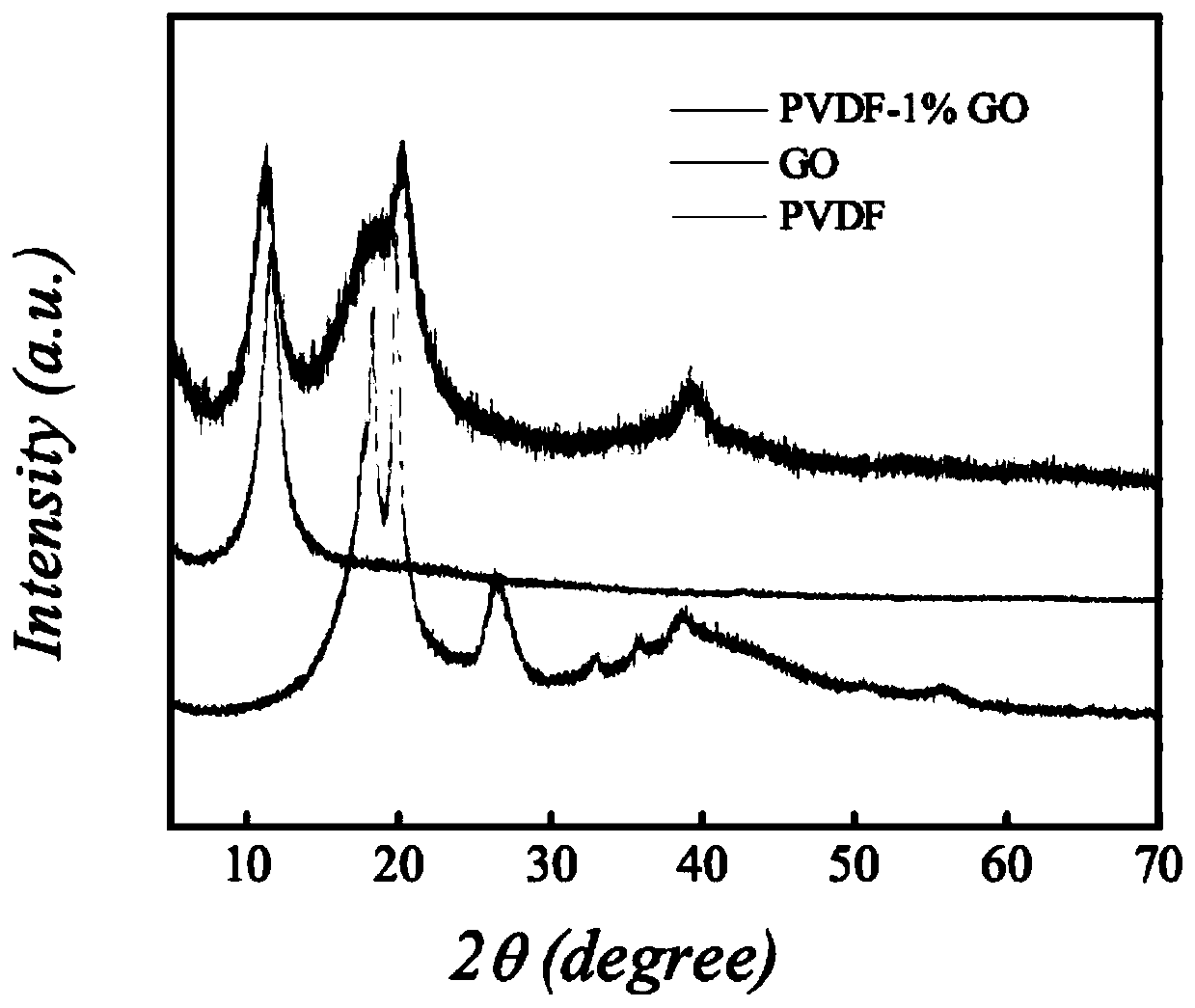

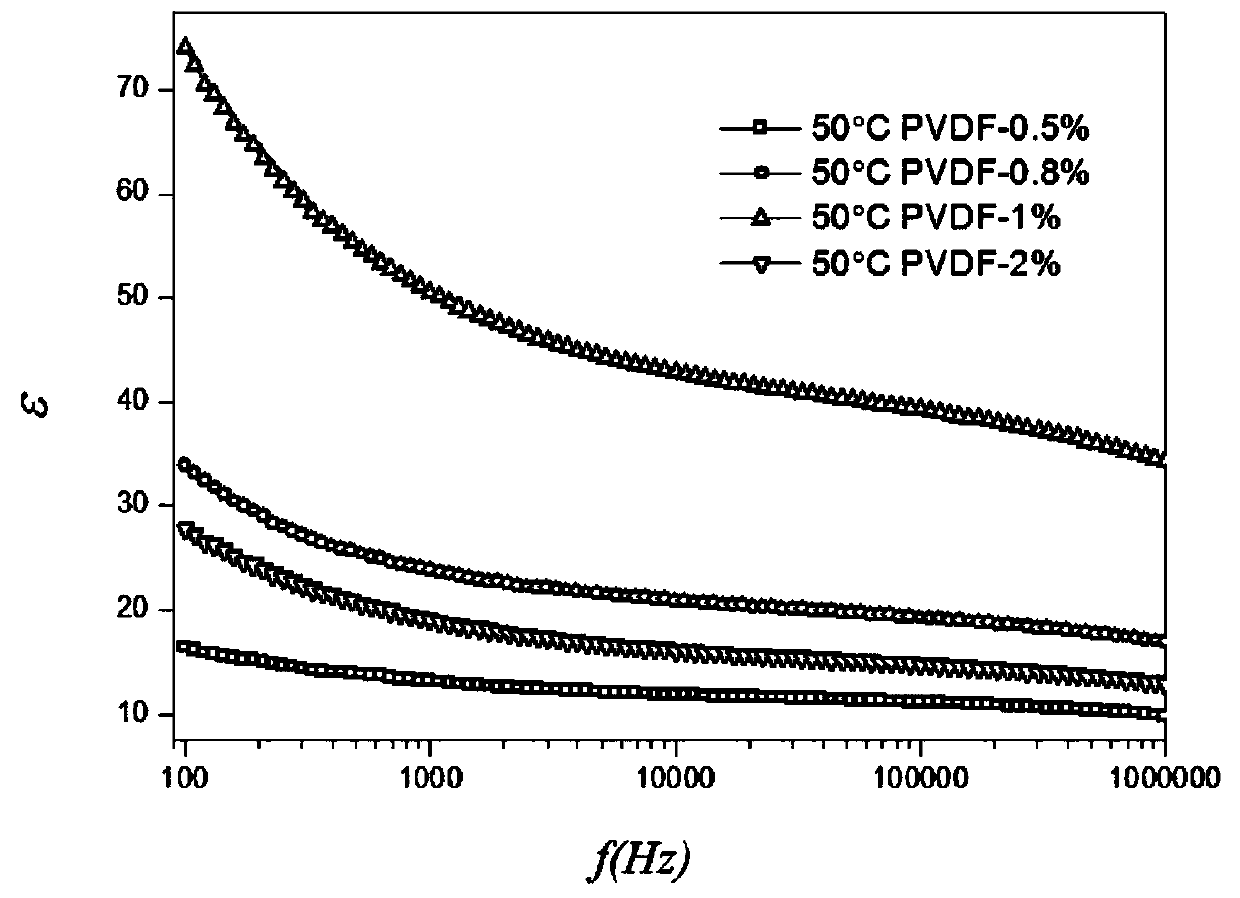

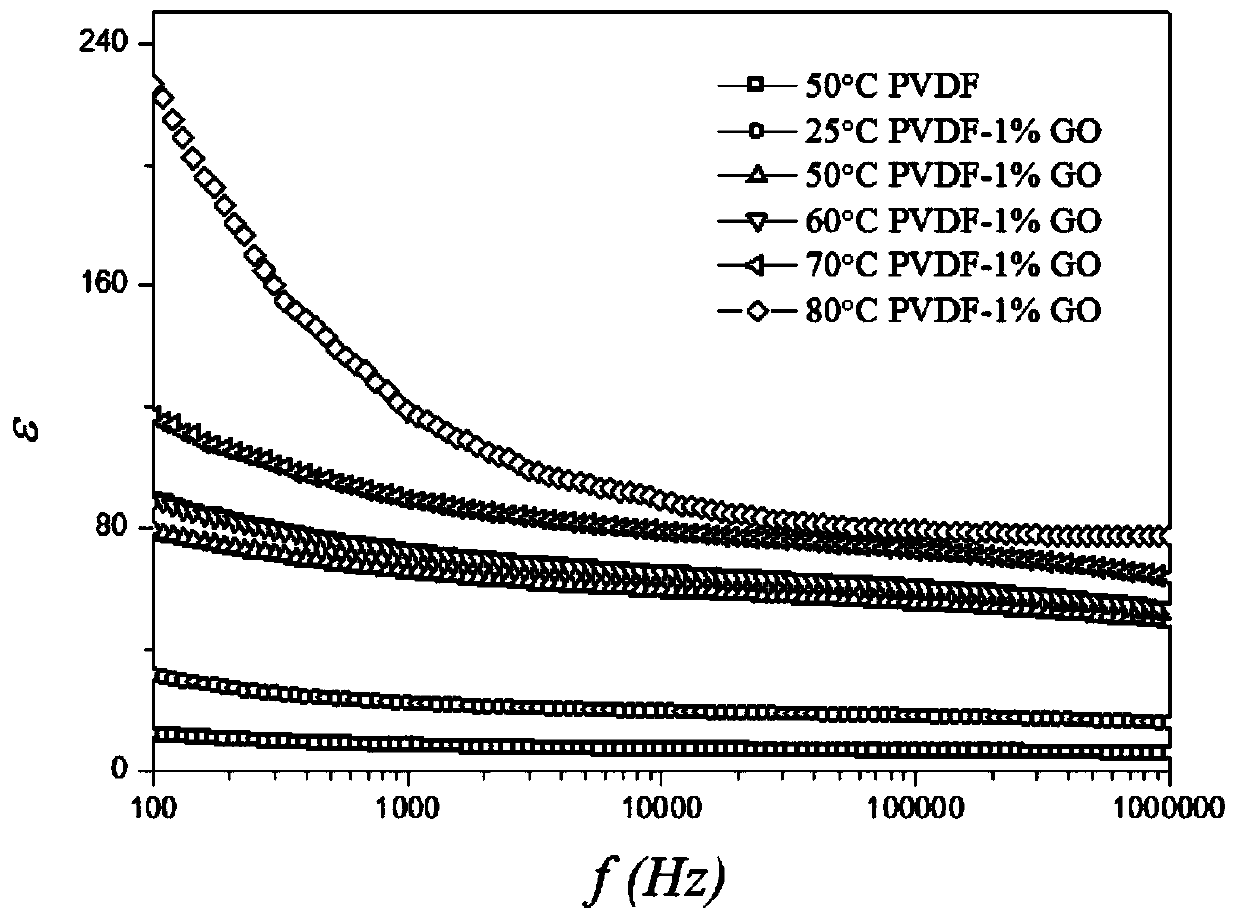

[0037] Example 1: Preparation of PVDF-1%GO composite membrane at 50°C

[0038] Step 1: Weigh a certain amount of GO and PVDF according to volume percentage 1:99.

[0039] The second step: at first, according to the mass percentage 7% of solute and solvent, the above-mentioned weighed PVDF powder is dissolved in the corresponding amount of N, N-dimethylformamide (DMF), stir on a magnetic stirrer for 2 Hours, a PVDF / DMF solution was obtained; then, the weighed GO was added to the PVDF / DMF solution, and the mixed solution was stirred on a magnetic stirrer at 50°C for another 3 hours and ultrasonically treated for 2 hours. Finally, let stand for 30 minutes to remove air bubbles.

[0040] Step 3: Slowly pour the solution that has been left standing on the cleaned flat silicon wafer, and wait for the solution to level off automatically to form a wet film.

[0041] Step 4: Move the above-mentioned silicon wafer with the wet film into a vacuum oven, dry it under vacuum at 50° C. for...

Embodiment 2

[0045] Example 2: Preparation of PVDF-0.5%GO composite membrane at 60°C

[0046] Step 1: Weigh a certain amount of GO and PVDF according to the volume percentage of 0.5:99.5.

[0047] The second step: at first, according to the mass percentage 7% of solute and solvent, the above-mentioned weighed PVDF powder is dissolved in the corresponding amount of N, N-dimethylformamide (DMF), stir on a magnetic stirrer for 2 Hours, a PVDF / DMF solution was obtained; then, the weighed GO was added to the PVDF / DMF solution, and the mixed solution was stirred on a magnetic stirrer at 60°C for another 2 hours and ultrasonically treated for 2 hours. Finally, let stand for 30 minutes to remove air bubbles.

[0048] Step 3: Slowly pour the solution that has been left standing on the cleaned flat silicon wafer, and wait for the solution to level off automatically to form a wet film.

[0049] Step 4: Move the above-mentioned silicon wafer with the wet film into a vacuum oven, dry it under vacuum ...

Embodiment 3

[0053] Example 3: Preparation of PVDF-1.5%GO composite membrane at 70°C

[0054] Step 1: Weigh a certain amount of GO and PVDF according to volume percentage 1.5:98.5.

[0055] Second step: at first, according to the mass percent of solute and solvent 7%, the above-mentioned weighed PVDF powder is dissolved in the corresponding amount of N,N-dimethylformamide (DMF), stir on a magnetic stirrer for 3 Hours, a PVDF / DMF solution was obtained; then, the weighed GO was added to the PVDF / DMF solution, and the mixed solution was stirred on a magnetic stirrer at 70°C for another 3 hours and ultrasonically treated for 3 hours. Finally, let stand for 30 minutes to remove air bubbles.

[0056] Step 3: Slowly pour the solution that has been left standing on the cleaned flat silicon wafer, and wait for the solution to level off automatically to form a wet film.

[0057] Step 4: Move the above-mentioned silicon wafer with the wet film into a vacuum oven, dry it under vacuum at 70° C. for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com