Method for improving enzymatic hydrolysis efficiency by adopting hydrothermal-microwave approach combined with ionic liquid for two-step pretreatment of lignocellulose raw material

A lignocellulose and ionic liquid technology, applied in the field of biomass energy utilization, can solve the problems of reduced concentration of tetrabutylammonium hydroxide, difficult temperature control, unfavorable sustainable mass production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Using hydrothermal pretreatment of lignocellulosic raw materials to improve enzymatic hydrolysis efficiency

[0031] 1) pulverizing the lignocellulose raw material into 100 mesh lignocellulose powder;

[0032]2) Accurately weigh 5 g of the lignocellulose powder obtained in step 1 and mix it with 50 mL of distilled water and heat it in a water bath for 2 hours at a temperature of 90°C; after the heating is completed, filter and dry to obtain a sample after hydrothermal pretreatment;

[0033] 3) Accurately weigh 4 g of sample I obtained in step 2, place it in a 50 mL Erlenmeyer flask, add 20 mL of sodium citrate buffer solution (pH=4.8), and simultaneously add cellulase 55 FPU / g substrate, and the amount of β-glucosidase is 75FPU / g substrate, sealed with plastic wrap and placed in a constant temperature oscillator at 180rpm / min, 55°C for 72h; then cooled to room temperature, 1mL of supernatant was taken, and the content of reducing sugar in the enzymatic soluti...

Embodiment 2

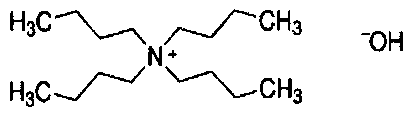

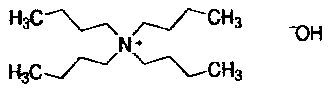

[0035] Example 2: Using [TBA][OH] in combination with distilled water to pretreat lignocellulosic raw materials to improve enzymatic hydrolysis efficiency

[0036] 1) pulverizing the lignocellulose raw material into 100 mesh lignocellulose powder;

[0037] 2) Accurately weigh 5g of the lignocellulose powder obtained in step 1, place it in a 75mL Erlenmeyer flask, add 40mL of ionic liquid and 10mL of distilled water at the same time, place it in a water bath and heat for 40min at a temperature of 60°C;

[0038] 3) After heating, centrifuge the solid-liquid mixture obtained in step 2 at a speed of 15000r / min for 10min, separate the solid from the liquid, and take the supernatant;

[0039] 4) Add absolute ethanol to the supernatant obtained in step 3 at a volume ratio of 1:3. Obtain the mixed solution containing the precipitate, dry and store the obtained precipitate after suction filtration, that is, obtain the sample after the hydrothermal pretreatment of the ionic liquid tetr...

Embodiment 3

[0043] Example 3: Using microwaves combined with distilled water to pretreat lignocellulosic raw materials to improve enzymatic hydrolysis efficiency

[0044] 1) pulverizing the lignocellulose raw material into 100 mesh lignocellulose powder;

[0045] 2) Accurately weigh 5g of the sample I obtained in step 1, put it in a 75mL conical flask, add 50mL distilled water at the same time, put it in a microwave reactor, set the microwave power to 700w, the microwave frequency to 2450HHz, and the time to 20min. dry to obtain a sample pretreated by microwave combined with distilled water;

[0046] 3) Accurately weigh 4 g of the sample obtained in step 2, place it in a 50 mL Erlenmeyer flask, add 20 mL of sodium citrate buffer solution (pH=4.8), and simultaneously add cellulase 55 FPU / g substrate, and the amount of β-glucosidase is 75FPU / g substrate, sealed with plastic wrap and placed in a constant temperature oscillator at 180rpm / min, 55°C for 72h; then cooled to room temperature, 1m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com