Ultra-small multi-component alloy composite material, its preparation method and its application

A multi-component alloy and composite material technology, applied in the field of nanomaterials, can solve the problems of cumbersome polymer synthesis, incapable of large-scale production, uneven particle size, etc., and achieve the effect of unique activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present application also provides a method for preparing the above-mentioned ultra-small multi-element alloy composite material, comprising the following steps:

[0037] Mix sulfur-doped mesoporous carbon, a metal salt precursor and a solvent, and dry to obtain an initial mixture; the metal salt precursor is a metal salt precursor of two or more different metal elements;

[0038] The initial mixture is heat-treated in a reducing atmosphere to obtain an ultra-small multi-element alloy composite material; the temperature of the heat treatment is 400-800°C.

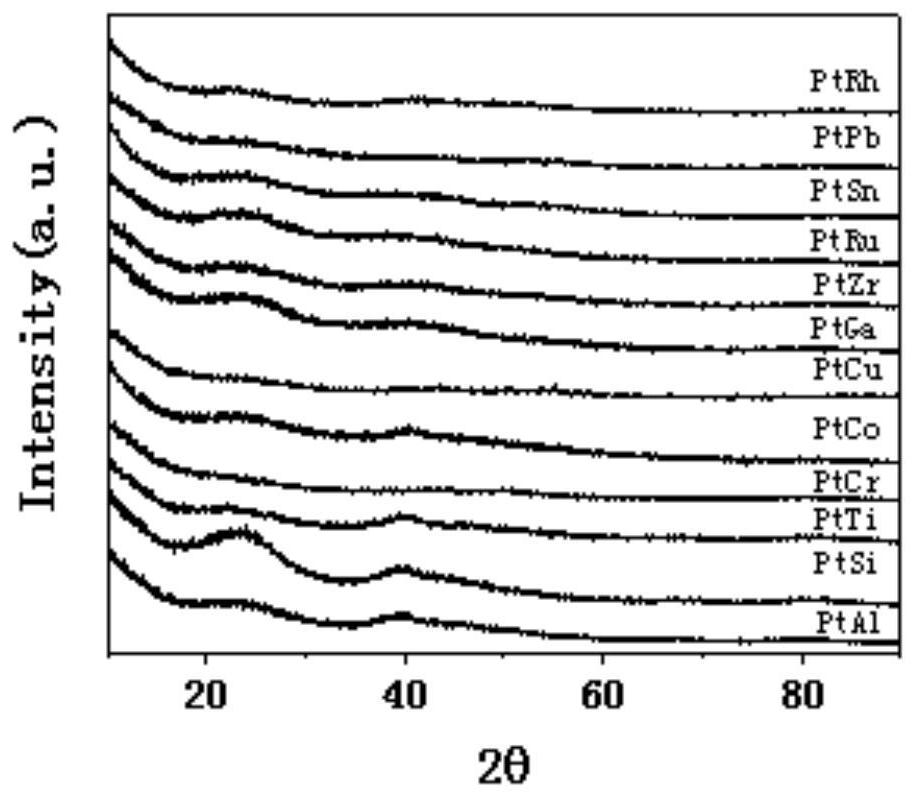

[0039] The ultra-small multi-element alloy composite material provided by the application can be prepared by impregnation and heat treatment. This method is universally applicable to various metals, and the process operation is simple and easy.

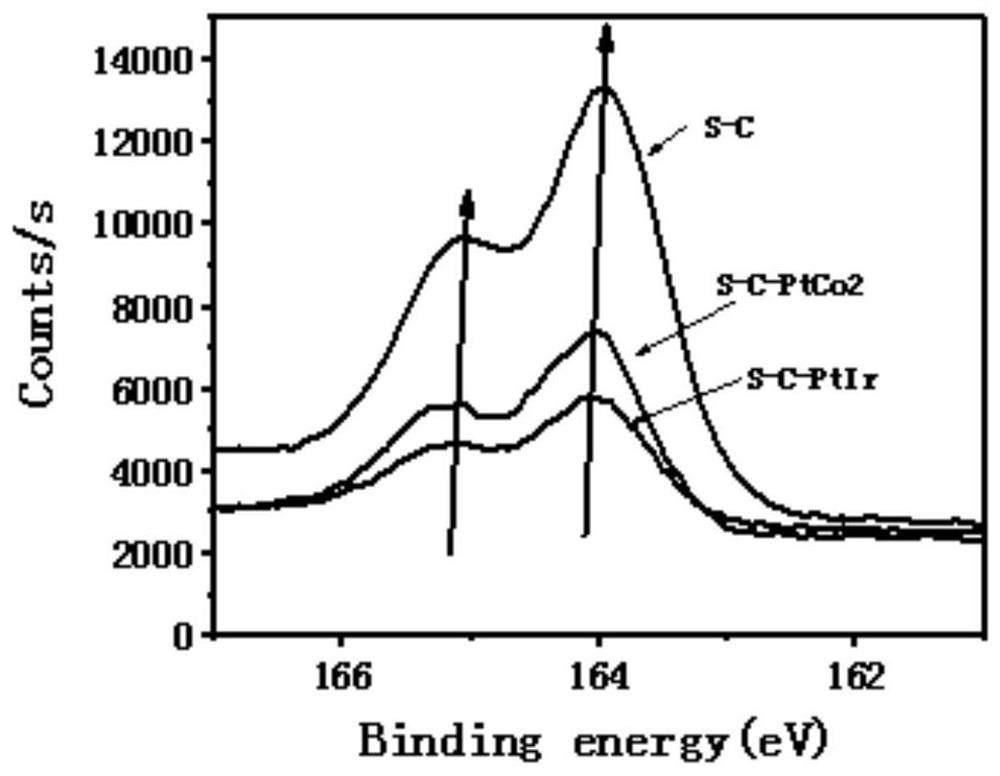

[0040] Specifically, in the process of preparing ultra-small multi-element alloy composite materials, the applicant first mixes sulfur-doped mesoporous carbon, metal salt...

Embodiment 1

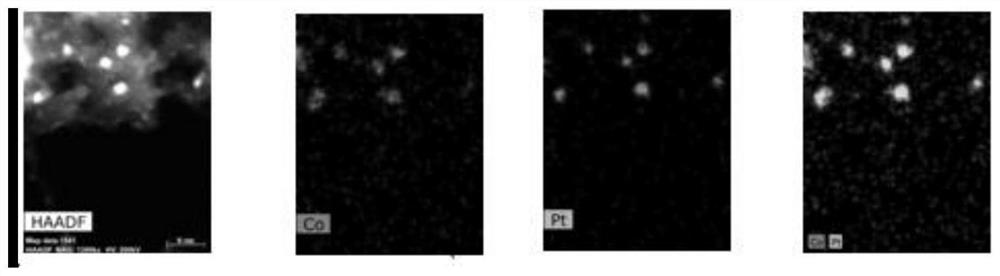

[0052] a. 0.5g dithiophene, 0.5g SiO 2 Airgel and 0.25g Co(NO 3 ) 2 ·6H 2 O is dispersed in tetrahydrofuran and stirred evenly, and the solvent is removed by rotary evaporation to obtain a uniform mixture; the obtained uniform mixture is transferred to a quartz crucible or a corundum crucible, put into a tube furnace, and then nitrogen is introduced as a protective gas, and the tube furnace Raise the temperature to 800°C at a rate of 5°C / min, and keep it for 2h; then cool down to room temperature naturally, and maintain normal pressure in the tube furnace; then transfer the obtained product to a flask, add about 2mol / L NaOH solution 40mL, and stir for 36h Alkali etching for the first time; then centrifuge the solution in a centrifuge at 8000r for 5min; then pour off the centrifuged supernatant, transfer the lower solid to the flask again, and add about 2mol / L NaOH solution About 40mL, stirred for 36h, and carried out the second alkali etching; finally, centrifuged and washe...

Embodiment 2

[0064] a. 0.5g dithiophene, 0.5g SiO 2 Airgel and 0.25g Co(NO 3 ) 2 ·6H 2O is dispersed in tetrahydrofuran and stirred evenly, and the solvent is removed by rotary evaporation to obtain a uniform mixture; the obtained uniform mixture is transferred to a quartz crucible or a corundum crucible, put into a tube furnace, and then nitrogen is introduced as a protective gas, and the tube furnace Raise the temperature to 800°C at a rate of 5°C / min, keep it for 2h, then cool down to room temperature naturally, and keep the normal pressure in the tube furnace; then transfer the obtained product to a flask, add about 40mL of 2mol / L NaOH solution, and stir for 36h , carry out the first alkaline etching; then centrifuge the solution in a centrifuge at 8000r for 5min, pour off the centrifuged supernatant, transfer the lower solid to the flask again, and add about 2mol / L About 40mL of NaOH solution, stirred for 36h, and carried out the second alkali etching; finally, centrifuged and wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com