Composite scaffold material and preparation method and application thereof

A composite scaffold and fiber skeleton technology, applied in the field of medicine, can solve problems such as poor biocompatibility, decreased repair effect, and volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

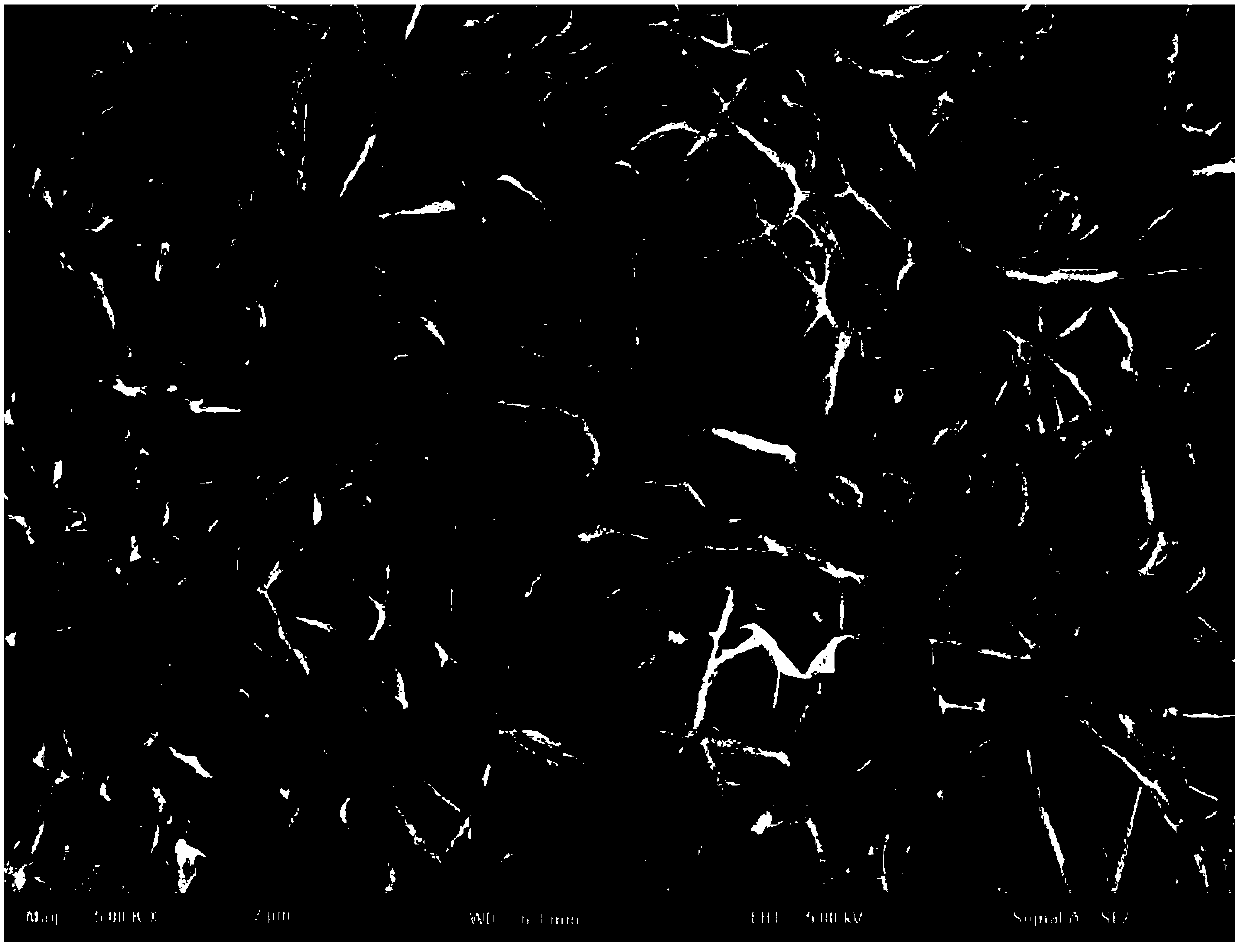

Image

Examples

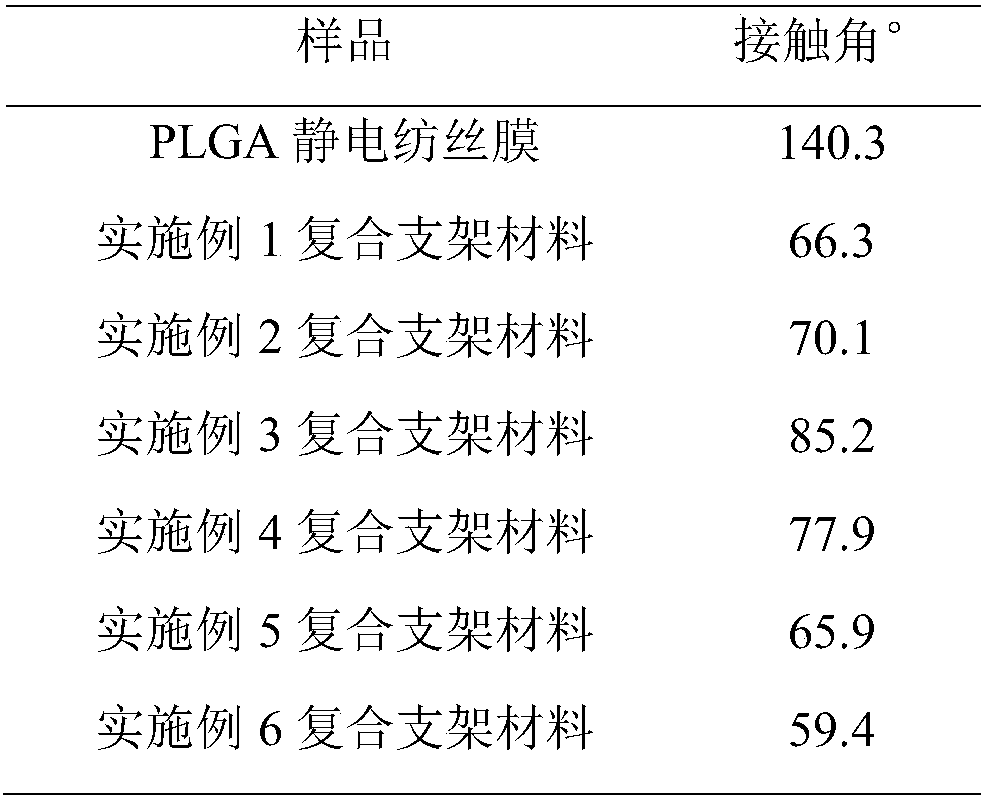

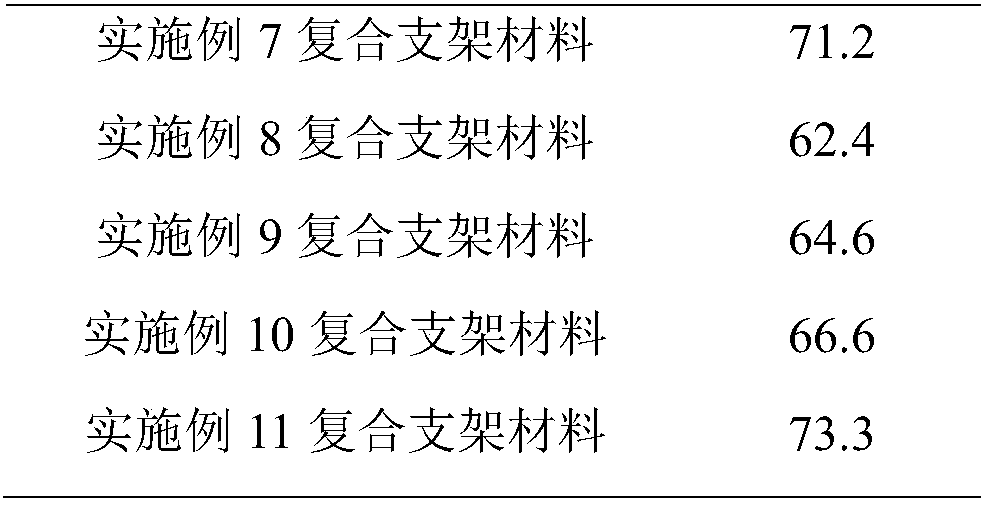

Embodiment 1

[0027] Prepare a petri dish with a diameter of 12cm (washed, sterilized and depyrogenated), dry it, and use it as an electrospinning receiver; weigh 1gPLGA and 0.2g collagen, add 10ml hexafluoroisopropanol, and prepare a degradable polymer The electrospinning A solution of the material PLGA and the material with cationic groups; add the above solution into the syringe of the electrospinning device, adjust the injection rate of the micro-injection pump to 0.1-0.3mm / min, adjust the positive voltage to 15V, and the negative voltage to 2V, The receiving distance of the receiving device was adjusted to 15 cm, and the fiber was received into a film-like structure to prepare an electrospun film A.

[0028] Weigh 0.5g of carboxymethyl dextran, dissolve in water, adjust pH=6, and prepare solution B with anionic groups; pour the above solution into the culture dish for preparing electrospun membrane A, soak, and dry into Membrane, a layer of carboxymethyl dextran membrane B was assemble...

Embodiment 2

[0031] Prepare a petri dish with a diameter of 12cm (washed, sterilized and depyrogenated), dried, and used as an electrospinning receiver; weigh 1g PLA and 0.2g chitosan, add 10ml hexafluoroisopropanol, and prepare a degradable A solution of polymer material PLA and material with cationic groups; add the above solution into the syringe of the electrospinning device, adjust the injection rate of the micro-injection pump to 0.5mm / min, adjust the positive voltage to 15V, and the negative voltage to 2V, and adjust the receiving device With a receiving distance of 10 cm, 20 layers of electrospun membrane A were electrospun.

[0032] Weigh 0.5 g of carboxymethyl dextran, dissolve in water, adjust pH=6, and prepare solution B of materials with anionic groups. The above solution was poured into the polypropylene petri dish for preparing the electrospun membrane A, soaked, and dried to form a membrane. The product is sterilized with ethylene oxide.

Embodiment 3

[0034] Prepare a petri dish with a diameter of 12 cm (washed, sterilized and depyrogenated), and dry it; weigh 0.5 g of hyaluronic acid, dissolve it in water, adjust the pH to 6, and prepare an anionic group material A solution. Spray the above A solution on a petri dish and dry it to form a film A; weigh 0.5g of chitosan, dissolve it in water, adjust the pH=4, prepare a cationic group material B solution, spray it on the film A, and make it Assembled under the action of electrostatic force, the electrostatic assembly was stacked 20 times continuously to obtain an electrostatic assembled film. Weigh 1g of PCL and 0.2g of polylysine, add 10ml of hexafluoroisopropanol, and prepare the degradable polymer material PCL and the electrospinning C solution of the material with cationic groups; add the above solution into the syringe of the electrospinning device, adjust The injection rate of the micro-injection pump was 1.0mm / min, the positive voltage was adjusted to 15V, the negative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com