Production process of pipe pile

A production process and pipe pile technology, applied in the direction of manufacturing tools, strengthening molding, ceramic molding machines, etc., can solve the problems of poor industrial applicability, energy waste, etc., and achieve the effects of high density, water conservation, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

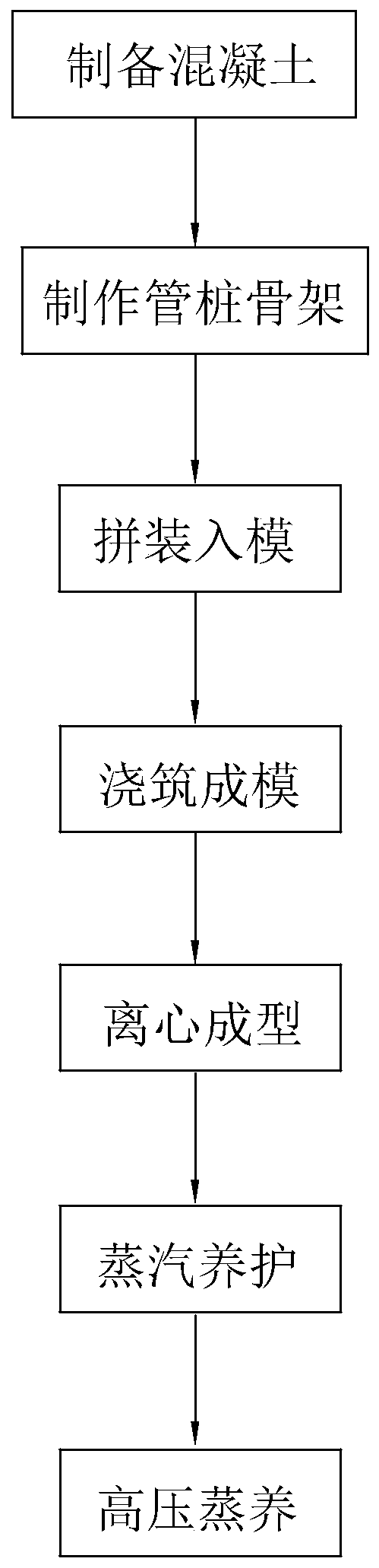

[0044] Embodiment 1: a kind of production technology of pipe pile, specifically comprises the following steps:

[0045] Step 1: Prepare concrete, dry and mix Portland cement, medium sand, fly ash, mineral powder, and stones, then add water and water reducing agent for mixing to obtain concrete for later use;

[0046] Step 2: Make the pipe pile skeleton, cut prestressed PC steel rods of equal length, fix multiple prestressed PC steel rods on the pier head of the seam welder, run the seam welder, and seam weld the spiral ribs on the prestressed PC On the steel bar, the two ends of the spiral reinforcement on the prestressed PC steel bar are contracted sections with a pitch of 45 mm, and the rest are extended sections with a pitch of 80 mm, and the length ratio of the contracted section to the extended section is 1:10, so that the pipe pile skeleton is obtained ;

[0047] Step 3: Assembling and loading the mold, disassembling the pipe pile mold into upper and lower half molds, h...

Embodiment 2-5

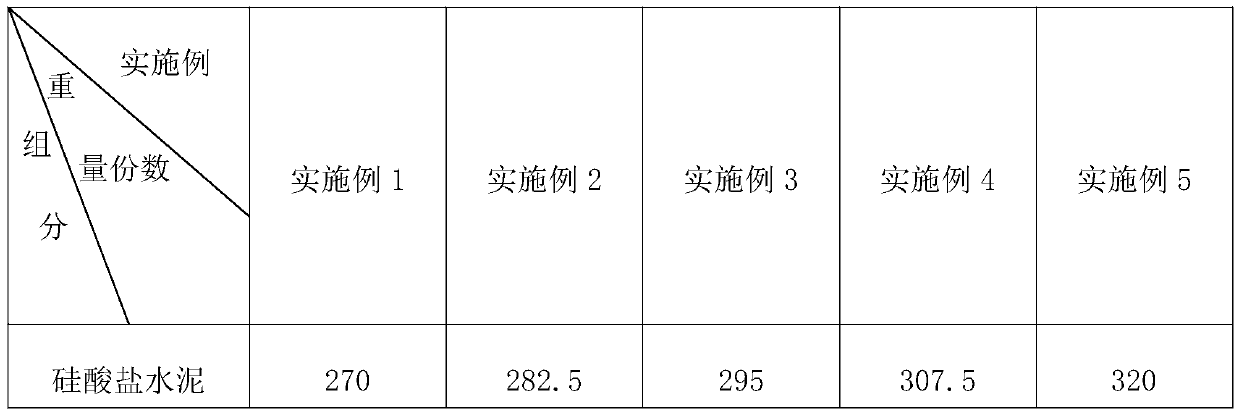

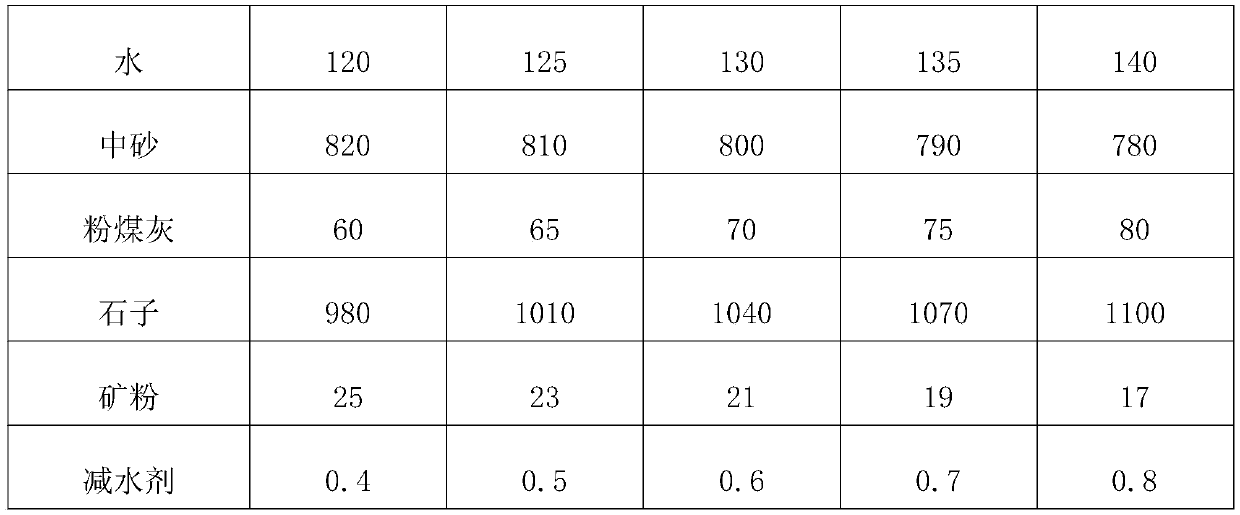

[0055] Embodiment 2-5: A production process of pipe piles. The difference from Embodiment 1 is that the components of the concrete and their corresponding parts by weight are shown in Table 1.

[0056] Each component of concrete and parts by weight thereof in Table 1 Embodiment 1-5

[0057]

[0058]

Embodiment 6

[0059] Embodiment 6: A production process of pipe piles. The difference from Embodiment 1 is that step 5 is specifically set as centrifugal molding, and the pipe pile mold after pouring into a mold is hoisted to a horizontal centrifuge for high-speed rotation. First keep the speed at 200rpm, run for 15min, then keep the speed at 500rpm, run for 15min, finally keep the speed at 300rpm, run for 12.5min, after standing for 10min, filter the slurry water in the pipe pile mold with a filter bag, and collect In the water storage tank, sample water 1 was obtained and stored for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com