A kind of aqueous electrolyte and aqueous metal ion battery

A water-based electrolyte, metal ion technology, applied in water-based electrolytes, secondary batteries, circuits, etc., can solve the problems of material dissolution, low capacity retention or Coulomb efficiency, and achieve high capacity retention and stable electrode/electrolyte interface. , the effect of good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1.1 Preparation of aqueous electrolyte

[0048] 3.64g triethyl phosphate, 2.12g LiClO 4 (anhydrous) and 0.018gH 2 O mixed (stabilizer: water: metal salt molar ratio = 2:0.1:2), heated and stirred at 80°C, and allowed to cool to room temperature to obtain an aqueous electrolyte solution.

[0049] 1.2 Performance test

[0050] (1) Electrochemical window test

[0051] The glassy carbon electrode was used as the working electrode, the platinum wire was used as the counter electrode, and the silver-silver chloride was used as the reference electrode, and the test was carried out as a three-electrode system.

[0052] The above-mentioned three-electrode system was subjected to a cyclic voltammetry test on a Sultron (Salartron Analytical 1470E electrochemical test system in the UK), with a voltage range of -2.5V to 2.5V and a scan rate of 20mV / s.

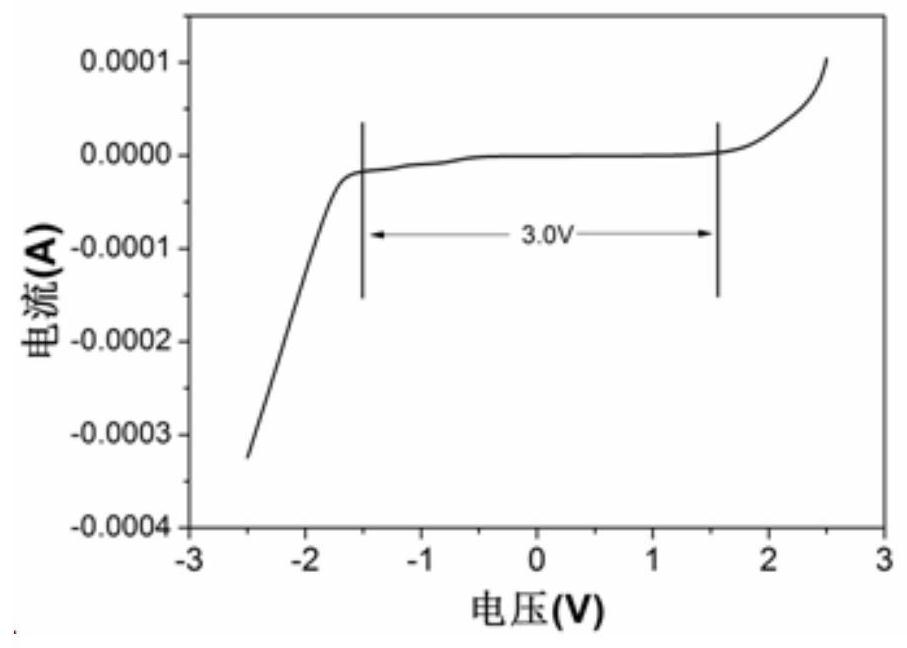

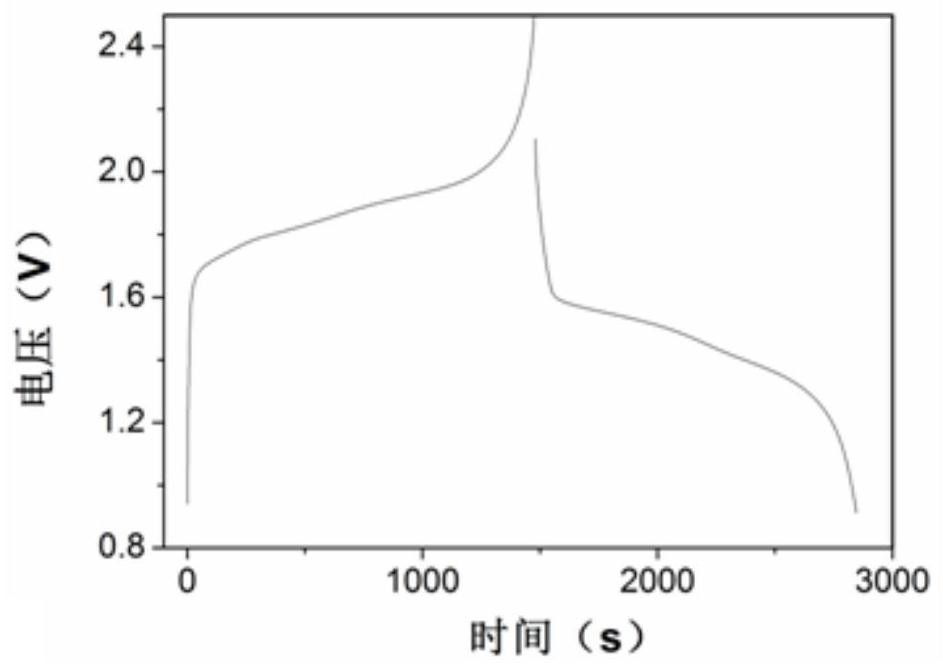

[0053] For test results see figure 1 , figure 1 From the cyclic voltammetry curve obtained in Example 1 of the present invent...

Embodiment 2~3

[0059] 1.1 Preparation of aqueous electrolyte

[0060] Prepare the aqueous electrolyte according to the preparation process of Example 1, the difference is that triethyl hemiphosphate is replaced by equimolar acetone; that is, the stabilizer is a mixture of triethyl phosphate and acetone, and the mixture of triethyl phosphate and acetone Molar ratio is 1:1, is recorded as embodiment 2.

[0061] The aqueous electrolyte solution was prepared according to the preparation process of Example 1, except that triethyl phosphate was replaced by acetone, which was recorded as Example 3.

[0062] 1.2 Performance test

[0063] According to the test method of Example 1, the performance tests of Examples 2-3 were carried out respectively, and compared with Example 1, the results are shown in Table 1.

[0064] The performance test result of table 1 embodiment 2-6

[0065] Electrochemical window, V Charge and discharge voltage, V Capacity retention Coulombic efficiency ...

Embodiment 4~5

[0069] 1.1 Preparation of aqueous electrolyte

[0070] Prepare the aqueous electrolyte solution according to the preparation process of Example 1, the difference is that the amount of water is increased to make the molar ratio of stabilizer: water: metal salt = 2:1:2; record it as Example 4.

[0071] The aqueous electrolyte was prepared according to the preparation process of Example 1, except that the amount of stabilizer was reduced so that the molar ratio of stabilizer: water: metal salt = 1:0.1:2; recorded as Example 5.

[0072] 1.2 Performance test

[0073] According to the test method of Example 1, the performance tests of Examples 4-5 were carried out respectively, and compared with Example 1, the results are shown in Table 2.

[0074] The performance test result of table 2 embodiment 7-8

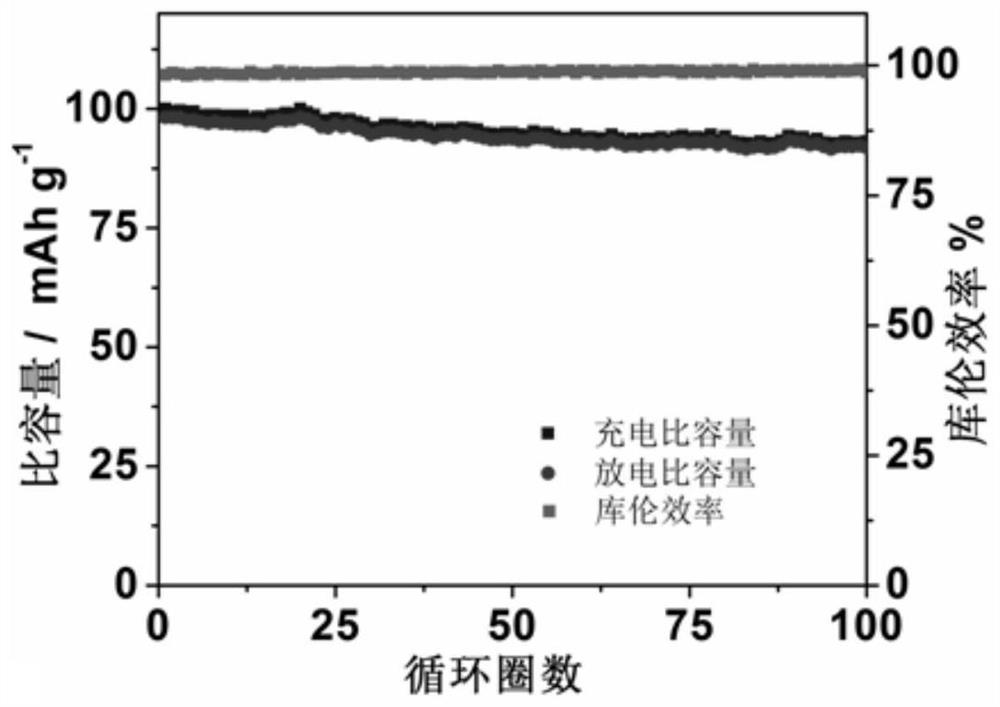

[0075] Electrochemical window, V Charge and discharge voltage, V Capacity retention Coulombic efficiency Example 1 3.0 2.5 94.6% 99.2% Example 4 2.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com