Lithium-containing silica sol doped PVDF composite gel polymer electrolyte film and preparation method thereof

A technology of electrolyte film and composite gel, which is applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems of failing to directly improve the lithium ion transfer capacity, and achieve the goal of promoting electrochemical performance, promoting crystallinity, and promoting reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Mix 11.8g KH560 with 20.8g TEOS, add hydrochloric acid dropwise to adjust the pH to 3, raise the temperature to 65°C, and react for 5 hours to form a silica sol. Then 2.4g LiOH was gradually added into the reaction system at this temperature, and the reaction was carried out for 2 hours to obtain a lithium-containing silica sol.

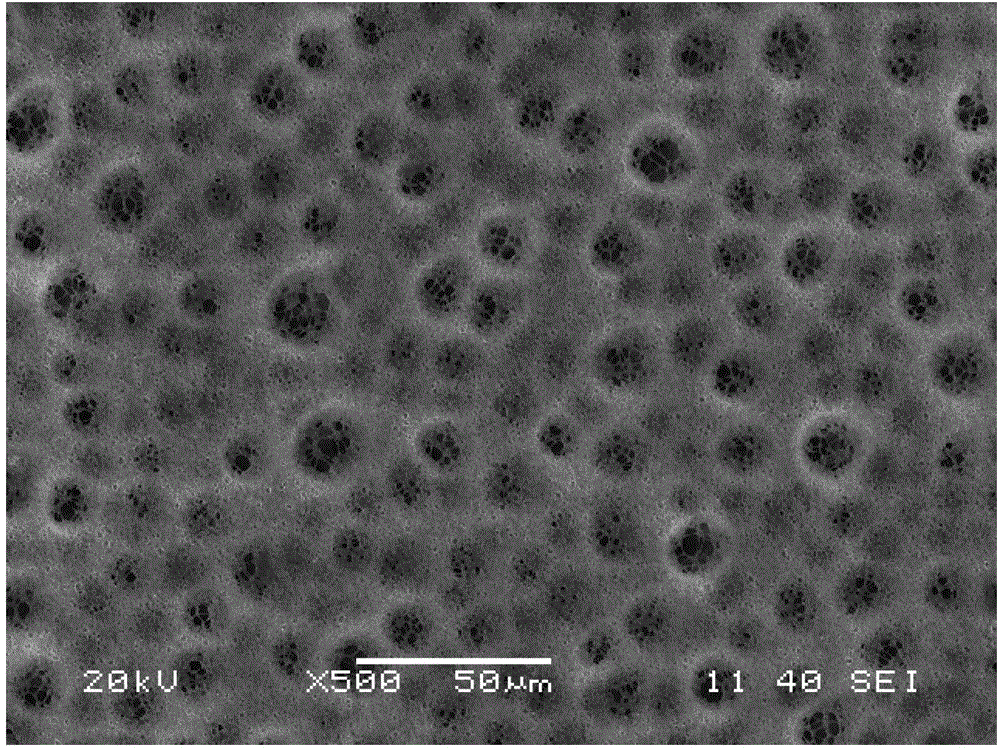

[0022] (2) The molecular weight of 9.6g is M n =5×10 5 Add PVDF powder into 55.53g of DMF solution, stir at room temperature for 18 hours, add 0.2g of lithium-containing silica sol, and stir for another 6 hours until completely dissolved. The polymer solution was left to defoam, and then spread on the glass plate with a spatula, and the thickness was controlled at 30 μm. Then, using methanol as the precipitant, the lithium-containing silica sol-doped PVDF composite porous membrane was prepared by immersion precipitation.

[0023] (3) Dry the lithium-containing silica sol-doped PVDF composite porous membrane under vacuum conditions at 80°...

Embodiment 2

[0028] (1) Mix 23.6g KH560 with 20.8g TEOS, add hydrochloric acid dropwise to adjust the pH to 2, raise the temperature to 70°C, and react for 6 hours to form a silica sol. Then 4.8g LiOH was gradually added into the reaction system at this temperature, and the reaction was carried out for 1.5 hours to obtain a lithium-containing silica sol.

[0029] (2) The molecular weight of 8g is M n =5×10 5 PVDF powder was added to 56.67g of DMF solution, stirred at room temperature for 12 hours, then 2g of lithium-containing silica sol was added, and stirred for another 12 hours until it was completely dissolved. After the polymer solution was left to defoam, it was evenly coated on a glass plate with a spatula, and its thickness was controlled at about 35 μm. Then, methanol was used as a precipitant to prepare a lithium-containing silica sol doped PVDF composite porous membrane by immersion precipitation.

[0030] (3) Dry the lithium-containing silica sol-doped PVDF composite porous m...

Embodiment 3

[0032](1) Mix 11.8g KH560 and 31.2g TEOS, add hydrochloric acid dropwise to adjust the pH to 4, raise the temperature to 75°C, and react for 7 hours to form a silica sol. Then 2.4g LiOH was gradually added into the reaction system at this temperature, and the reaction was carried out for 1 hour to obtain a lithium-containing silica sol.

[0033] (2) The molecular weight of 10g is M n =5×10 5 PVDF powder was added to 73.67g of DMF solution, stirred at room temperature for 24 hours, then 3g of lithium-containing silica sol was added, and stirred for another 8 hours until completely dissolved. After the polymer solution was left to defoam, it was evenly coated on a glass plate with a spatula, and its thickness was controlled at about 50 μm. Then, methanol was used as a precipitant to prepare a lithium-containing silica sol doped PVDF composite porous membrane by immersion precipitation.

[0034] (3) Dry the lithium-containing silica sol doped PVDF composite porous membrane unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com