Heat-resisting cast aluminum alloy with high elongation and pressure casting preparation method thereof

A technology of casting aluminum alloy and high elongation rate, which is applied in the field of high elongation heat-resistant casting aluminum alloy and its pressure casting preparation, can solve the problems of elongation rate, insufficient heat resistance, application restrictions, etc., and achieve improved recycling rate, The effect of reducing inclusion requirements, improving mechanical properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

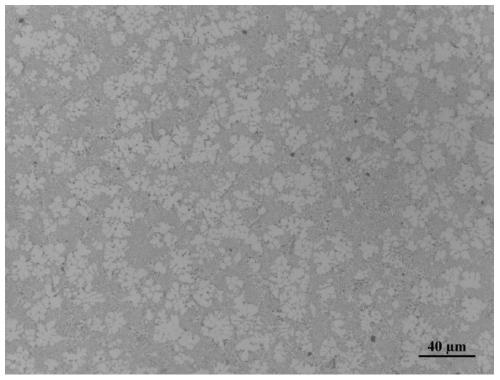

Image

Examples

Embodiment 1

[0038] The weight percent of a high-elongation heat-resistant cast aluminum alloy is: according to the theoretical ratio, 9.0% Si, 0.05% Cu, 0.05% Mg, 0.05% Sc, 0.3% Zr, the balance is Al and unavoidable impurities Fe .

[0039] Its preparation method is:

[0040] (1) After properly considering the burning loss, calculate the amount of raw materials required according to the above alloy composition and stoichiometric ratio; remove the oxide layer from industrial pure aluminum ingots, industrial pure magnesium ingots and Al-Si master alloy AlSi23 and dry them in advance. Heat to 200°C; calculate the amount of raw materials required according to the composition and stoichiometric ratio of the alloy;

[0041] (2) After melting the industrial pure aluminum ingots accounting for 25% of the height of the crucible into a molten pool at 710°C, add the remaining aluminum ingots;

[0042] (3) After the aluminum ingot is completely melted, the temperature is raised to 720°C, and the Al...

Embodiment 2

[0048] The weight percent of a high-elongation heat-resistant cast aluminum alloy is: according to the theoretical ratio, 11.0% Si, 0.4% Cu, 0.02% Mg, 0.1% Sc, 0.3% Zr, 0.1% Ti, and the balance is Al and not Avoid impurity Fe.

[0049] The preparation method is as follows: (1) Remove the oxide layer from industrial pure aluminum ingots, industrial pure magnesium ingots and Al-Si master alloy AlSi28, dry and preheat to 200°C; calculate the required the amount of raw material used;

[0050] (2) After melting the industrial pure aluminum ingots accounting for 25% of the height of the crucible into a molten pool at 715°C, add the remaining aluminum ingots;

[0051] (3) After the aluminum ingot is completely melted, the temperature is raised to 720°C, and the Al-Si master alloy is added in 3 times, and the temperature is kept constant at 715°C;

[0052] (4) After the Al-Si master alloy is completely melted, heat up to 760°C, add AlCu50, AlZr4 master alloy, AlTi5 master alloy, AlS...

Embodiment 3

[0057] The weight percent of a high-elongation heat-resistant cast aluminum alloy is: according to the theoretical ratio, 12.0% Si, 0.4% Cu, 0.05% Mg, 0.1% Sc, 0.1% Zr, 0.1% Ti, 0.2% V, the balance It is Al and unavoidable impurity Fe.

[0058] Its preparation method is:

[0059] (1) Remove the oxide layer from industrial pure aluminum ingots, industrial pure magnesium ingots and Al-Si master alloy AlSi23 and dry and preheat to 200°C; calculate the amount of raw materials required according to the composition and stoichiometric ratio of the alloy;

[0060] (2) After melting the industrial pure aluminum ingots accounting for 25% of the height of the crucible into a molten pool at 710°C, add the remaining aluminum ingots;

[0061] (3) After the aluminum ingot is completely melted, the temperature is raised to 720°C, and the Al-Si master alloy is added in 2 times, and the temperature is kept constant at 710°C;

[0062] (4) After the Al-Si master alloy is completely melted, rais...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com