Dampproof cabinet and its manufacturing method

A manufacturing method and cabinet technology, which is applied in the field of moisture-proof cabinets and its manufacture, can solve the problems of shortened service life of cabinets, mildew of wooden substrates, and poor moisture-proof performance, and achieve long service life, no oil penetration, and good moisture-proof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

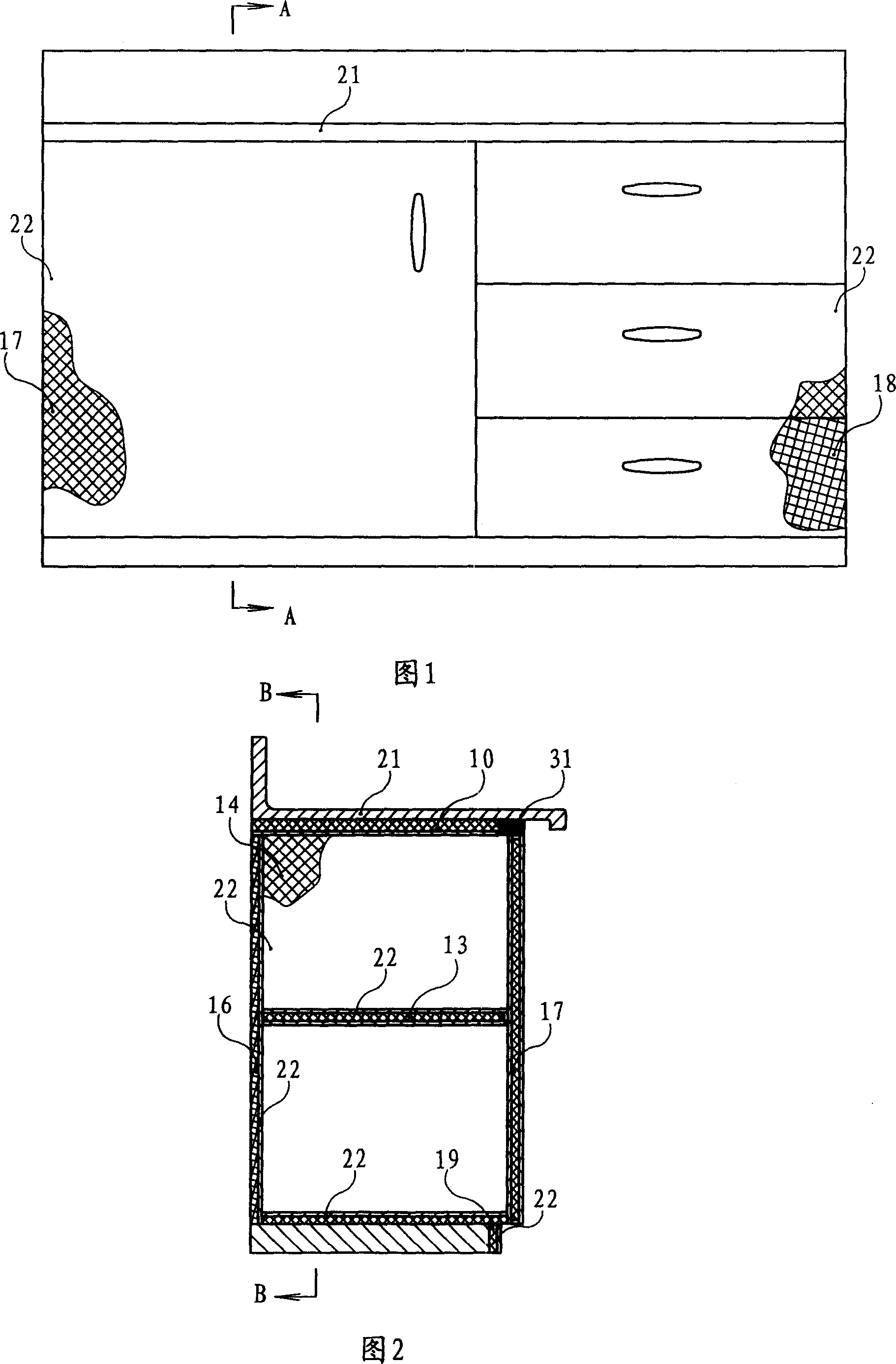

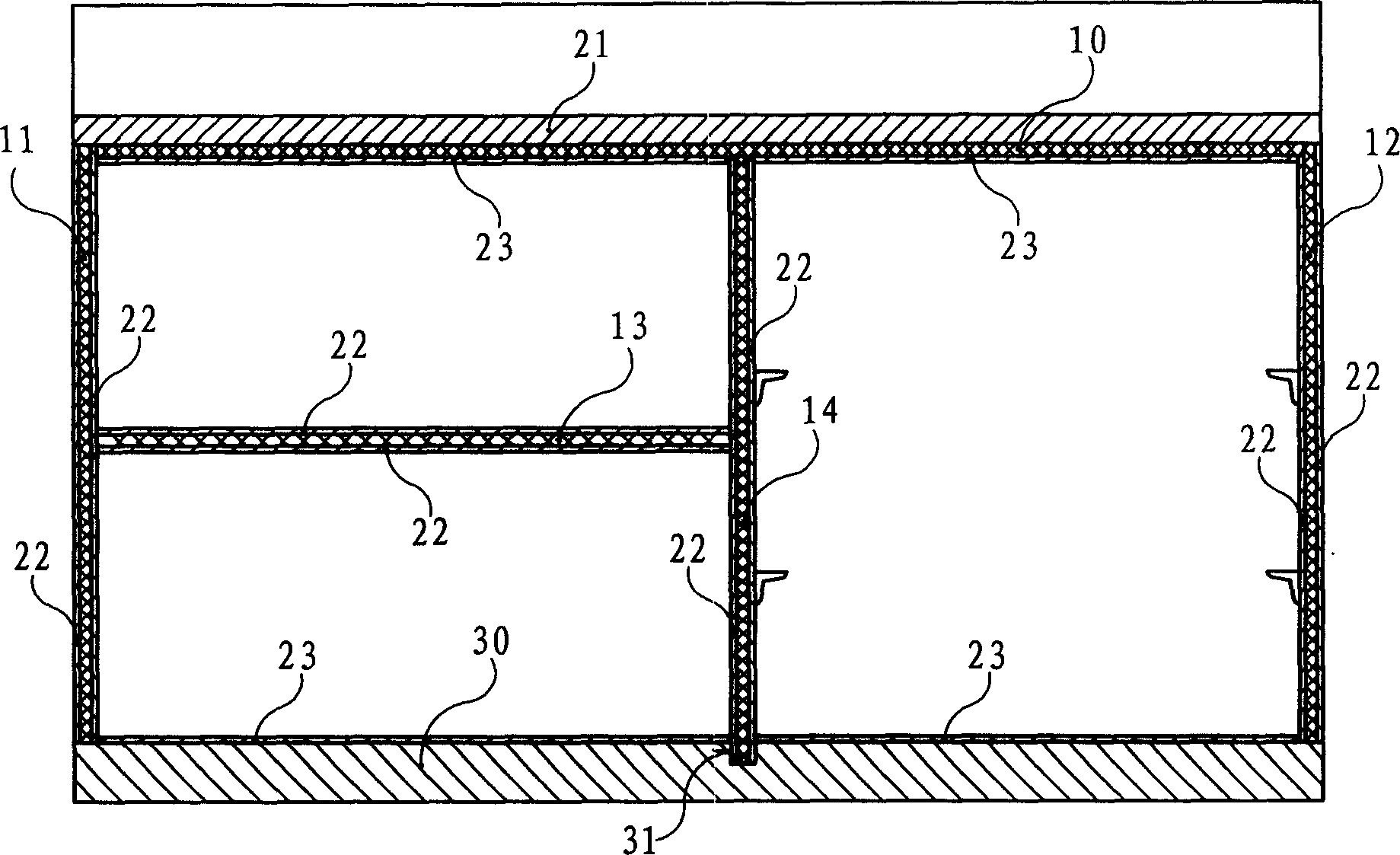

[0035] Figure 1, Figure 2, image 3As shown, the moisture-proof cabinet of the present invention comprises a cabinet body frame made of substrates (such as table top substrate 10, side vertical plate substrates 11 and 12, bottom plate substrate 15, etc.), the substrate forming the cabinet body is a concrete prefabricated board, and the cabinet body frame The top is covered with slabs of artificial marble forming the visible side of the cabinet. Above-mentioned artificial marble plate is divided into two kinds, and one of them is the artificial marble countertop 21 that thickness is 20mm, is used as the countertop on the countertop substrate 10; Other inner and outer visible faces of the panel. The artificial marble table top 21 , the artificial marble table thin plate 22 and the outer surface or inner surface of the corresponding substrate are bonded with marble glue added with a matching curing agent.

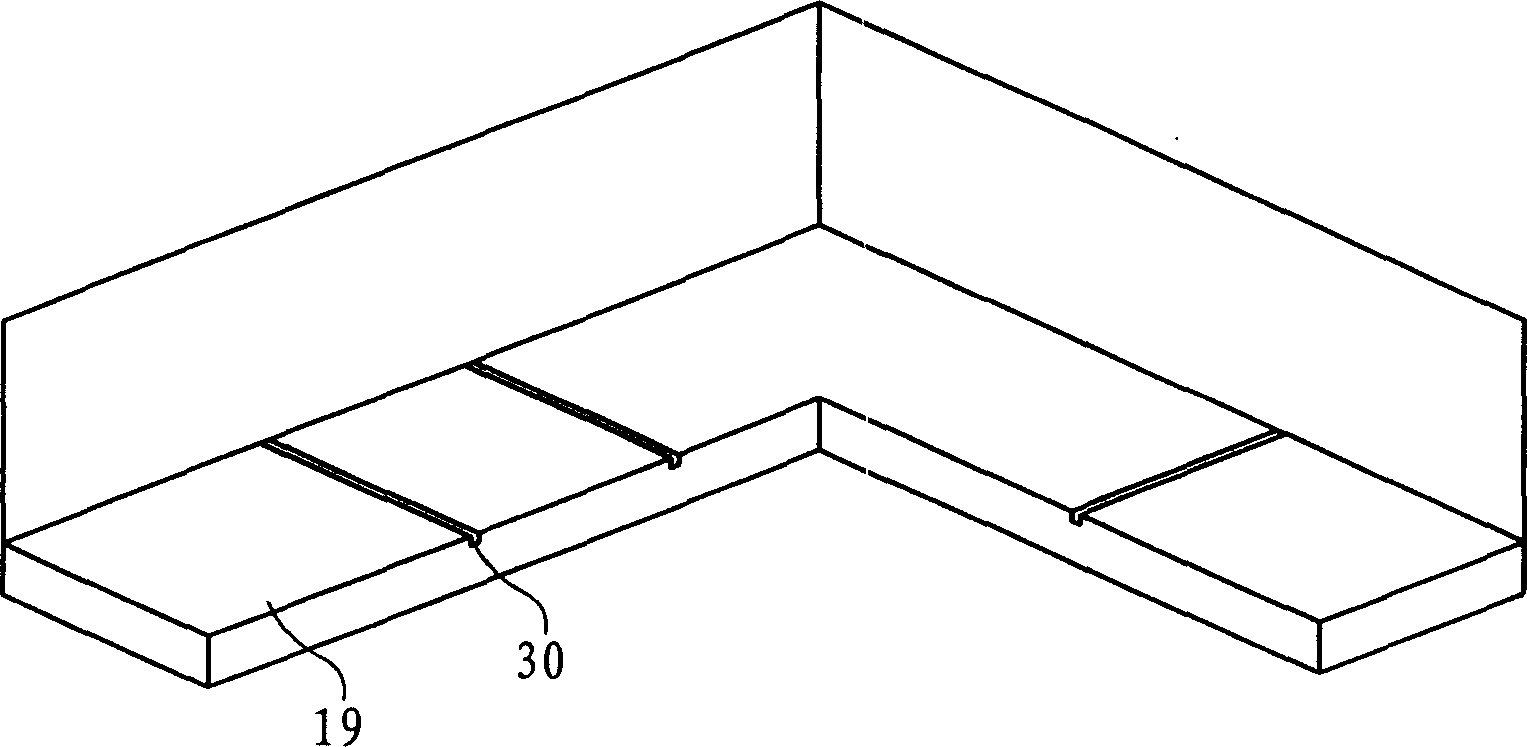

[0036] Such as Figure 4 As shown, the base plate 15 is directly arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com