Durable concrete colored tile

A technology for durable concrete and colored tiles, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as large porosity, weak adhesion, paint peeling, etc., to enhance bending resistance , the effect of reducing porosity and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

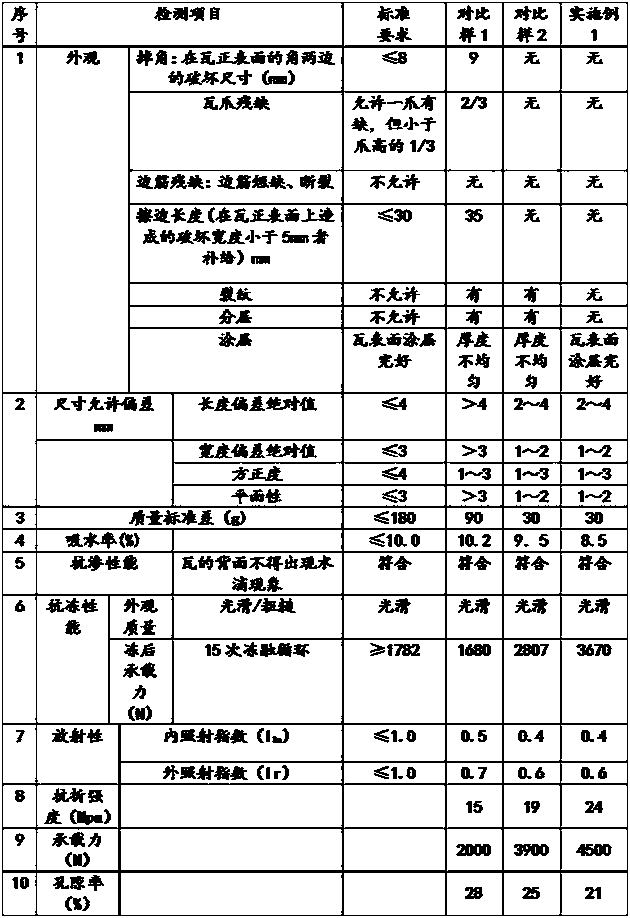

Examples

Embodiment 1

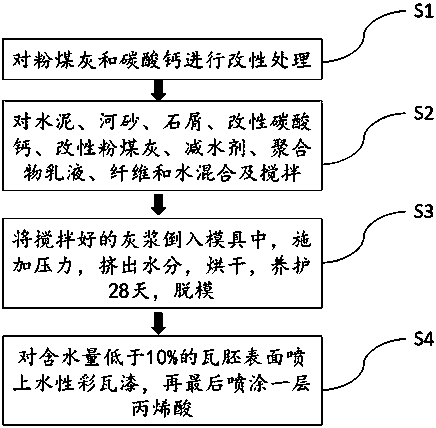

[0035] Such as figure 1 As shown, the preparation steps of the durable concrete color tile are as follows:

[0036] S1: To modify the fly ash and calcium carbonate, first soak the fly ash in 10% mass fraction of hydrochloric acid, put it into the reaction kettle, keep the temperature at 100°C, stir for 24 hours, and then use 10% mass fraction of hydrochloric acid Rinse with sodium hydroxide 5 times, then rinse with clean water and dry, soak the dried fly ash into 6% by mass titanate coupling agent, the solid-liquid ratio is 3 / 5, stir and soak for 24 hours; soak the nano-scale calcium carbonate in 75% mass percent ethanol solution, put it into a centrifuge, disperse for 3 hours, dry it, add it to 5% mass percent titanate coupling agent and stir for 4 hours, filter ,drying.

[0037] S2: The mass fraction is based on kilograms. Put 75 kilograms of cement, 35 kilograms of modified fly ash, 25 kilograms of river sand and 40 kilograms of stone chips into the mixing tank and stir, ...

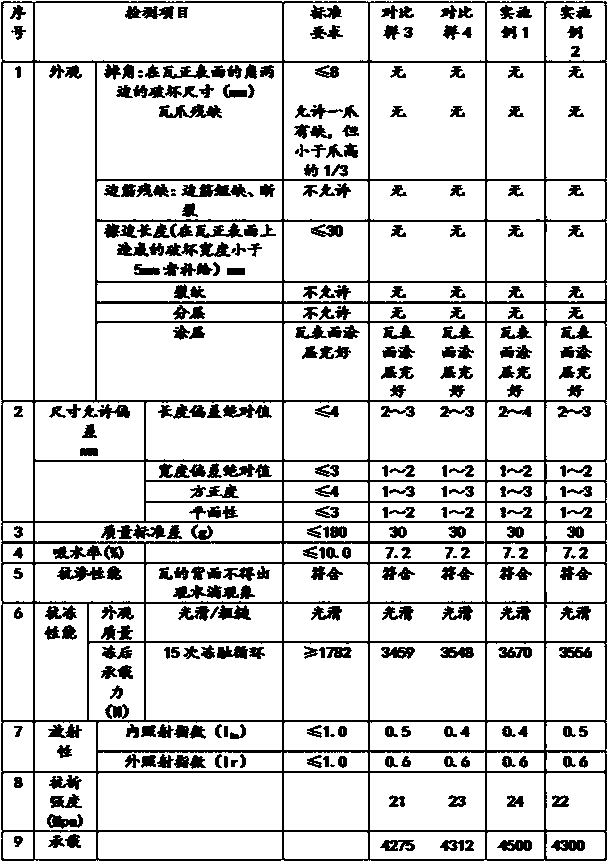

Embodiment 2

[0051] The concrete colored tile and its preparation method in this embodiment are improvements on the basis of Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to the content disclosed in this embodiment.

[0052] Such as figure 1 As shown, the preparation steps of the durable concrete color tile are as follows:

[0053] S1: Modification of fly ash and calcium carbonate.

[0054] S2: The mass fraction is based on kilograms. Put 75 kilograms of cement, 35 kilograms of modified fly ash, 25 kilograms of river sand and 40 kilograms of stone chips into the mixing tank and stir, and add fiber and polymer in two times. Emulsion, water, modified calcium carbonate and water reducer, after the first addition, add 2.5 kg of epoxy emulsion, 16 kg of water, 1.5 kg of aramid fiber, 10 kg of modified calcium carbonate and 0.2 kg of polycarboxylic acid Water reducer, stirred for 2min, adde...

Embodiment 3

[0065] The concrete colored tile and its preparation method in this embodiment are improvements on the basis of Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to the content disclosed in this embodiment.

[0066] The preparation steps of the durable concrete colored tiles are as follows:

[0067] S1: Preparation of modified fly ash and modified calcium carbonate.

[0068] S2: The mass fraction is based on kilograms. Put 75 kilograms of cement, 35 kilograms of modified fly ash, 25 kilograms of river sand and 40 kilograms of stone chips into the mixing tank and stir, and add fiber and polymer in two times. Emulsion, water, modified calcium carbonate and water reducer, after the first addition, add 2.5 kg of epoxy emulsion, 16 kg of water, 1.5 kg of polypropylene fiber, 10 kg of modified calcium carbonate and 0.2 kg of polycarboxylic acid Water reducer, stirring for 2min, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com