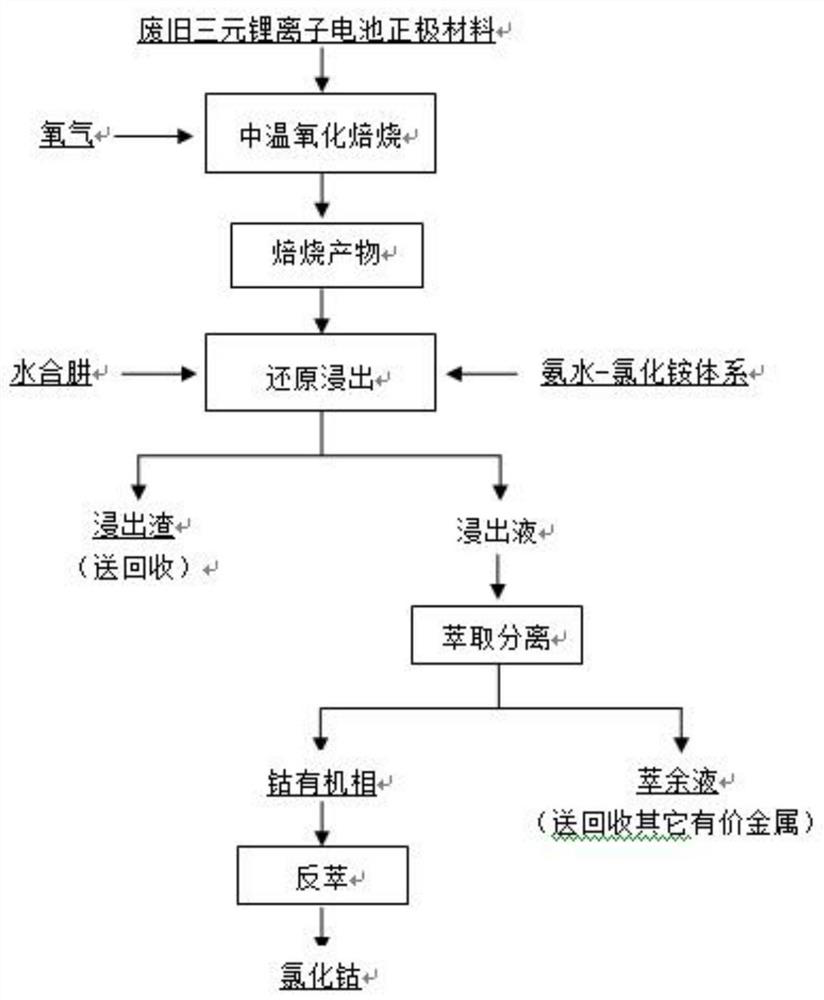

A method for recovering valuable metals from waste ternary lithium ion cathode materials

A cathode material and valuable metal technology, applied in the field of metallurgy, can solve the problems of high metal recovery rate, low product purity, large processing capacity by precipitation method, etc., achieve high metal leaching rate, good extraction effect, and promote valuable metal leaching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Waste ternary lithium ion battery cathode material, its main components are (%): Li 5.31, Ni 28.35, Co10.35, Mn 13.17, Fe 0.26, Al 0.71, Cu 0.05, C 2.11; industrial grade oxygen, of which O 2 Content ≥99.5%; technical grade ammonium chloride, of which NH 4 Cl content ≥ 99.5%; industrial grade ammonia water, of which NH 3 ·H 2 O content is 25-28%; industrial grade hydrazine hydrate, of which N 2 h 4 ·H 2 O content is 80%, industrial grade sodium hydroxide, of which NaOH≥96%; industrial grade hydrochloric acid, of which HCl content is 36-38%; industrial grade Versatic 911, of which Versatic 911 content is ≥99%.

[0022] Weigh 10.00 g of the waste ternary lithium-ion battery powder of the above components, add it to a quartz crucible, place the quartz crucible in a roasting furnace, seal the roasting furnace and start to feed oxygen, control the flow rate of oxygen fed to 500mL / min, normal temperature After passing oxygen for 15 minutes, the roasting furnace began to ...

Embodiment 2

[0026] Waste ternary lithium ion battery powder, its main components are (%): Li 5.13, Ni 28.80, Co 11.40, Mn14.78, Fe 0.21, Al 0.60, Cu 0.03, C 1.81; industrial grade oxygen, of which O 2 Content ≥99.5%; technical grade ammonium chloride, of which NH 4 Cl content ≥ 99.5%; industrial grade ammonia water, of which NH 3 ·H 2 O content is 25-28%; industrial grade hydrazine hydrate, of which N 2 h 4 ·H 2 O content is 80%, industrial grade sodium hydroxide, of which NaOH≥96%; industrial grade hydrochloric acid, of which HCl content is 36-38%; industrial grade Versatic 911, of which Versatic 911 content is ≥99%.

[0027] Weigh 100.00 g of the waste ternary lithium-ion battery powder of the above ingredients, add it to a quartz crucible, place the quartz crucible in a roasting furnace, seal the roasting furnace and start to feed oxygen, control the flow rate of oxygen fed to 500mL / min, normal temperature After passing oxygen for 20 minutes, the roasting furnace began to heat up ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Evaporation rate | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com