Photocatalysis compound filling material for micro pollution raw material pretreatment and preparation method thereof

A composite filler and pretreatment technology, which is applied in the direction of light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of unsatisfactory photocatalytic efficiency, difficult industrialization, and insufficient firmness, so as to improve photocatalytic activity , strong fluidity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

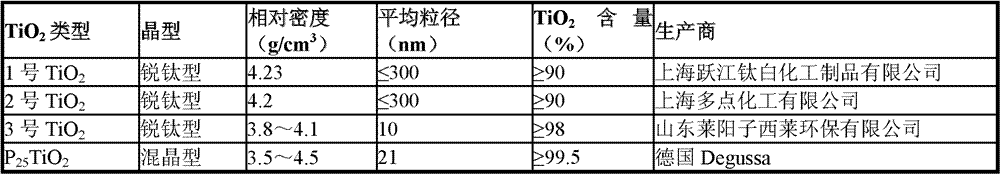

[0025] Example 1: Mix 20mg of titanate coupling agent and 10mL of ethanol, heat to 80°C, stir evenly, after reacting for 3 hours, add 1% TiO by mass ratio 2powder, and fully stirred until the ethanol boils and volatilizes to a small amount of solvent (about 1-2ml), and then repeatedly adds ethanol with the same mass ratio. Repeat the above method 2 times. Put the obtained viscous colloid in an oven, adjust the temperature to 80°C, dry it for 12 hours, crush and grind the obtained solid, and set it aside for use.

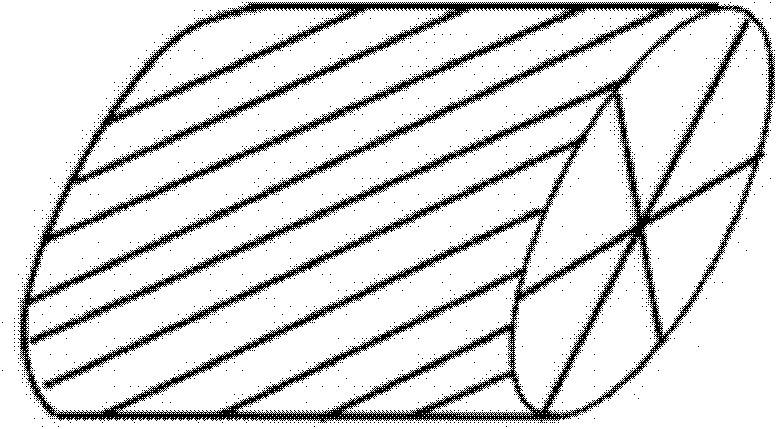

[0026] Polypropylene raw material and pretreated TiO 2 Blended on a twin-screw extruder, TiO 2 The mass fraction of the polypropylene is 8%, and the material enters the screw channel from the feeding port, so that the polypropylene raw material is gradually melted into a melt in the screw channel, and is output at a temperature of 180°C and a pressure of 78kPa, and is extruded by the screw. Shaped as oblique twist. The prepared composite filler has a diameter of ...

Embodiment 2

[0027] Example 2: Mix 25mg of titanate coupling agent and 15mL of ethanol, heat to 85°C, stir evenly, after 4.5 hours of reaction, add TiO with a mass ratio of 1.5% 2 powder, and fully stirred until the ethanol boils and volatilizes to a small amount of solvent (about 1-2ml), and then repeatedly adds ethanol with the same mass ratio. Repeat the above method 3 times. Put the obtained viscous colloid in an oven, adjust the temperature to 85°C, dry for 18 hours, crush and grind the obtained solid, and set it aside.

[0028] Polypropylene raw material and pretreated TiO 2 Blended on a twin-screw extruder, TiO 2 The mass fraction of the polypropylene is 9%, and the material enters the screw channel from the feeding port, so that the polypropylene raw material is gradually melted into a melt in the screw channel, and is output at a temperature of 190°C and a pressure of 94kPa, and is extruded by the screw. Shaped as oblique twist. The prepared composite filler has a diameter of ...

Embodiment 3

[0029] Example 3: Mix 30mg of titanate coupling agent and 20mL of ethanol, heat to 90°C, stir evenly, and after 6 hours of reaction, add TiO with a mass ratio of 2%. 2 powder, and fully stirred until the ethanol boils and volatilizes to a small amount of solvent (about 1-2ml), and then repeatedly adds ethanol with the same mass ratio. Repeat the above method 4 times. Put the obtained viscous colloid in an oven, adjust the temperature to 95°C, dry for 24 hours, crush and grind the obtained solid, and set it aside for use.

[0030] Polypropylene raw material and pretreated TiO 2 Blended on a twin-screw extruder, TiO 2 The mass fraction is 10%, and the material enters the screw channel from the feeding port, so that the polypropylene raw material is gradually melted into a melt in the screw channel, and is output at a temperature of 200 ° C and a pressure of 110kPa, and is extruded by the screw. Shaped as oblique twist. The prepared composite filler has a diameter of 15-25mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com