Preparation method and application of green manganese-doped silicate fluorescent material

A fluorescent material and manganese doping technology, applied in the field of fluorescent materials, can solve the problems of low absorption intensity, short afterglow time, low quantum efficiency, etc., and achieve the effects of low equipment requirements, simple preparation process and high luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a green manganese-doped silicate fluorescent material, the preparation of which includes the following steps:

[0044] (1) According to the chemical formula Zn 1.92 mn 0.08 SiO 4 Composition, reduce the ZnO in the experimental raw material by 15% of its stoichiometric ratio, weigh 0.5983gZnO, 0.0414gMnCO 3 , 0.2075gSiO 2 , and grind for 30 minutes to mix the raw materials evenly to obtain a mixed powder;

[0045] (2) Put the mixed powder into a corundum crucible, put it into a tubular atmosphere furnace, raise the temperature up to 800°C at a rate of 5°C / min, keep it warm for 2 hours, and then raise it to 1250°C at a rate of 5°C / min ℃, keep warm for 4h, then drop to 800°C at a rate of 5°C / min, hold for 2h, and finally drop to 500°C at a rate of 5°C / min, then cool to room temperature naturally, take out the obtained powder and grind it into powder Get the required phosphor material.

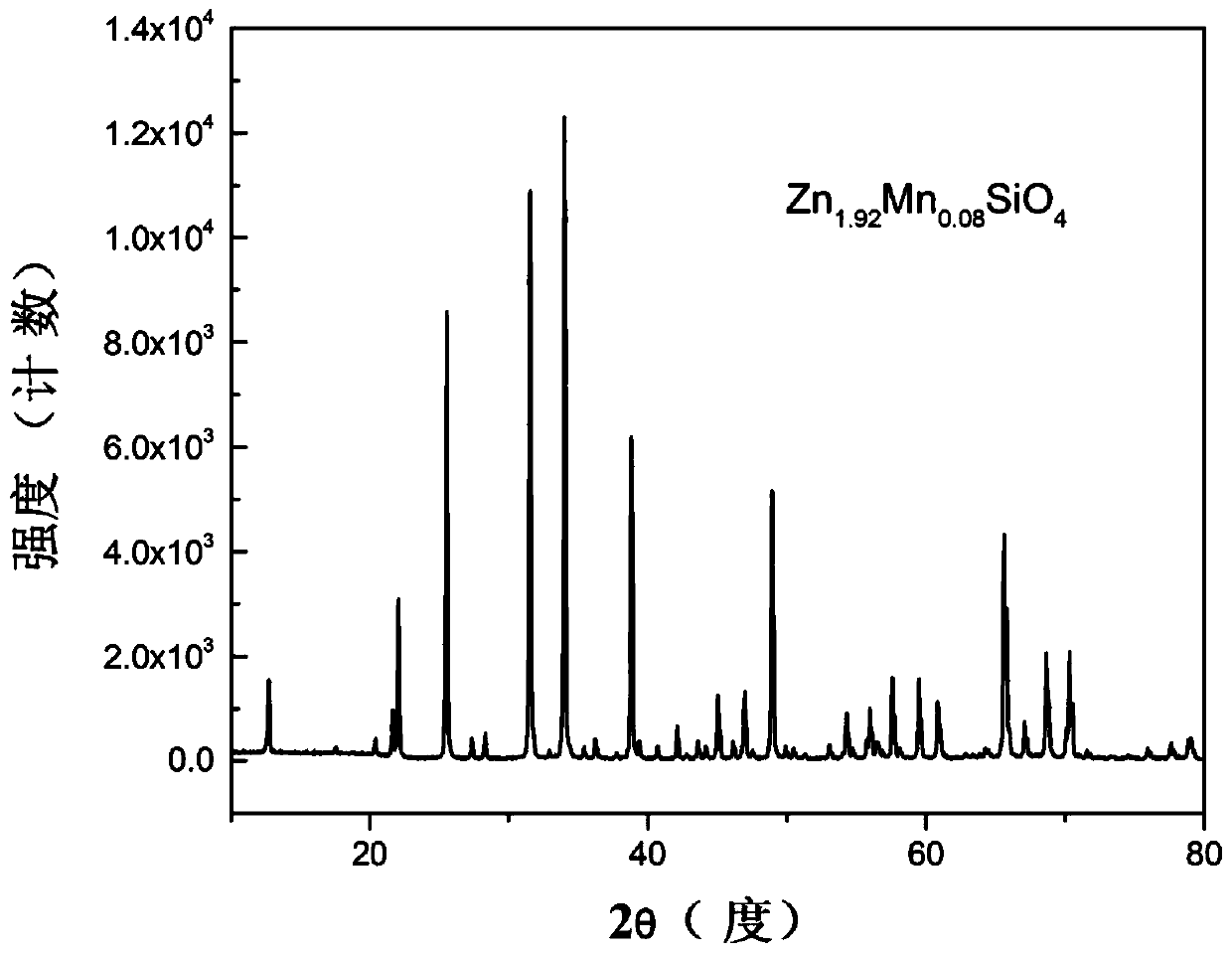

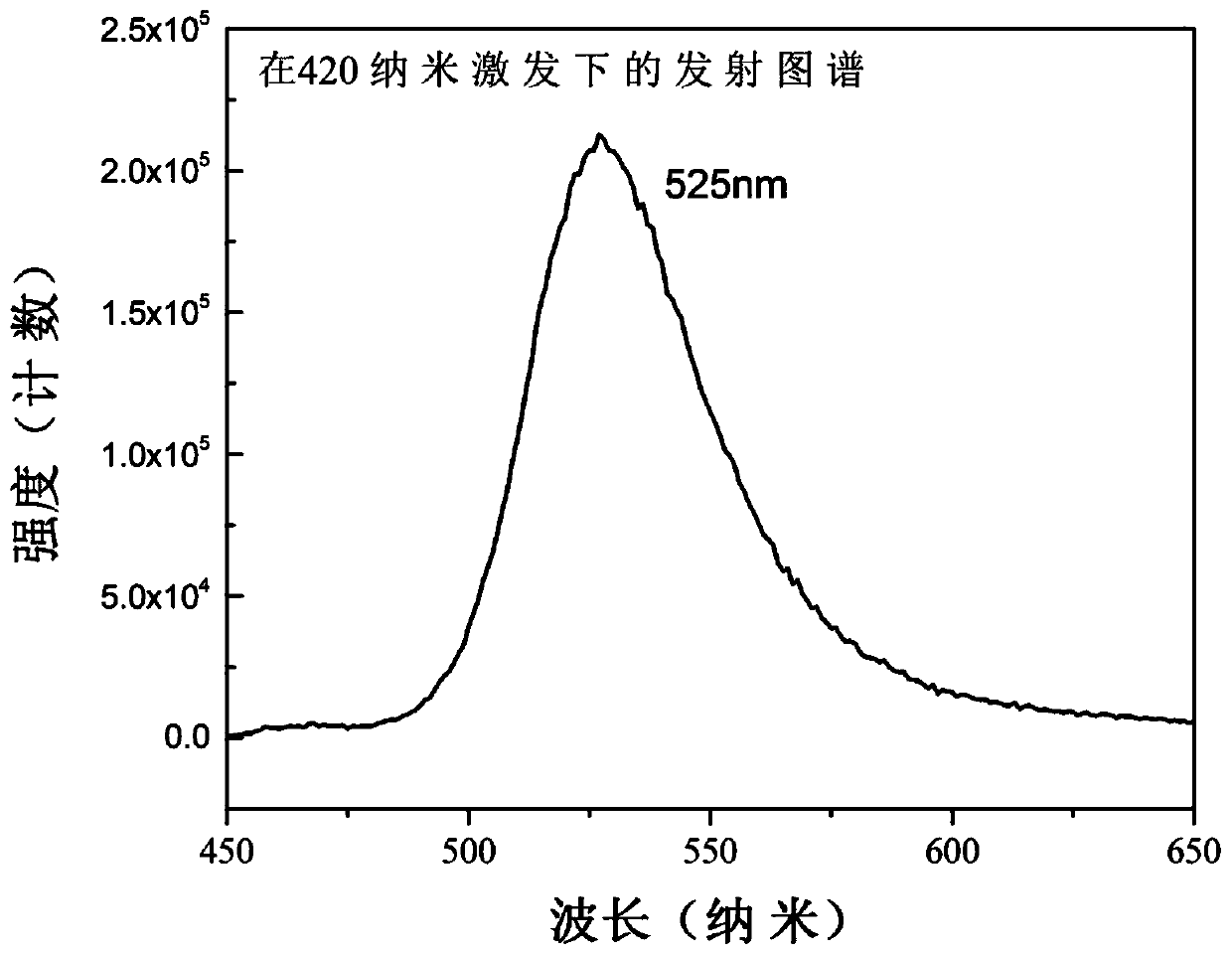

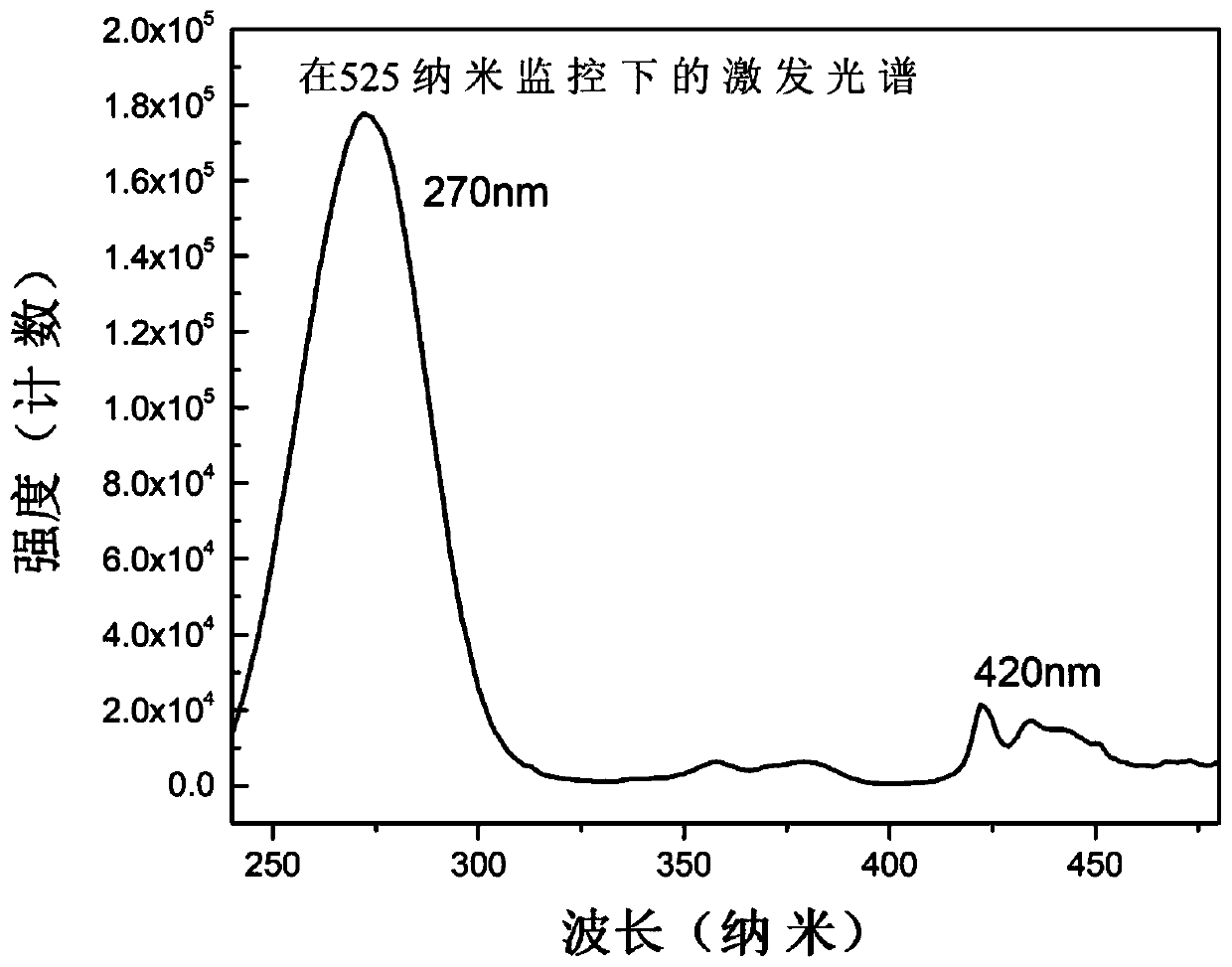

[0046] Figure 7 Shown is the XRD spectrum of the fluor...

Embodiment 2

[0048] This embodiment provides a green manganese-doped silicate fluorescent material, the preparation of which includes the following steps:

[0049] (1) According to the chemical formula Zn 1.92 mn 0.08 SiO 3.9 N 0.1 Composition, reduce the ZnO in the experimental raw material by 15% of its stoichiometric ratio, weigh 0.5988gZnO, 0.2505gSiO 2 , 0.0158gSi 3 N 4 and 0.0414gMnCO 3 , and grind for 30 minutes to mix the raw materials evenly to obtain a mixed powder;

[0050] (2) Put the mixed powder into a corundum crucible, put it into a tube-type atmosphere furnace, and 2 Under the atmosphere, the temperature was raised to 800°C at a rate of 5°C / min, kept for 2 hours, and then raised to 1250°C at a rate of 5°C / min, kept for 4 hours, and then the reducing gas H was introduced. 2 , lowered to 800°C at a rate of 5°C / min, kept for 2 hours, and finally cooled to room temperature at a rate of 5°C / min to 500°C, then the obtained powder was taken out and ground into a powder to...

Embodiment 3

[0052] This embodiment provides a green manganese-doped silicate fluorescent material, the preparation of which includes the following steps:

[0053] (1) According to the chemical formula Zn 1.92 mn 0.08 SiO 3.8 N 0.2 Composition, reduce the ZnO in the experimental raw material by 15% of its stoichiometric ratio, weigh 0.5993gZnO, 0.2304gSiO 2 , 0.0317gSi 3 N 4 and 0.0415gMnCO 3 , and grind for 30 minutes to mix the raw materials evenly to obtain a mixed powder;

[0054] (2) Put the mixed powder into a corundum crucible, put it into a tube-type atmosphere furnace, and 2 Under the atmosphere, the temperature was raised to 800°C at a rate of 5°C / min, kept for 2 hours, and then raised to 1250°C at a rate of 5°C / min, kept for 4 hours, and then the reducing gas H was introduced. 2 , lowered to 800°C at a rate of 5°C / min, kept for 2 hours, and finally cooled to room temperature at a rate of 5°C / min to 500°C, then the obtained powder was taken out and ground into a powder to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com