Organic-inorganic composite lubricating protective coating material with excellent space-environment resistance

A space environment, inorganic composite technology, applied in the direction of coating, etc., can solve the gaps in adhesion, impact resistance and lubrication performance, restrict the life and reliability of space equipment, and cannot meet the actual use needs, etc., to achieve good adhesion , low friction coefficient and long wear life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of organic-inorganic composite resin: Weigh H 3 PO 4 35 g, CrO 3 7g, Al(OH) 3 14g, water 20g, put into a container and raise the temperature to 90~100°C and stir for 1~2 hours to form a homogeneous phase; when the temperature is lowered to below 40°C, add 24 g of PTFE emulsion and continue to stir for 4 hours, cool to room temperature and discharge;

[0024] Preparation of lubricating coating: Weigh 13 g of organic-inorganic composite resin, 18 g of tungsten disulfide, 10 g of antimony trioxide, 3.5 g of cerium trifluoride, and 55.5 g of water; mix the raw materials and disperse them evenly by ball milling to obtain a lubricating coating ;

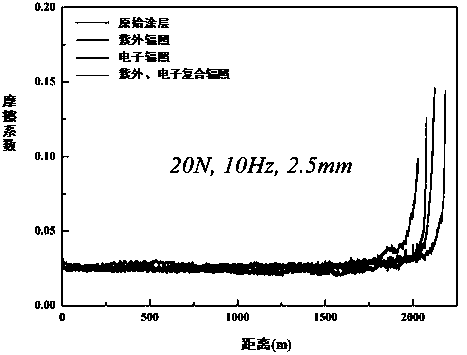

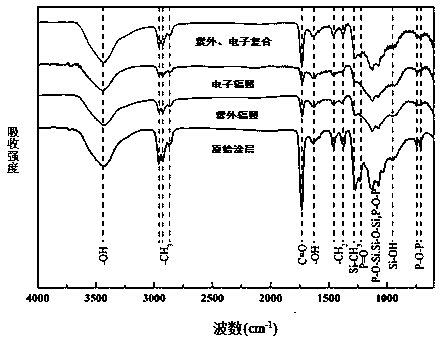

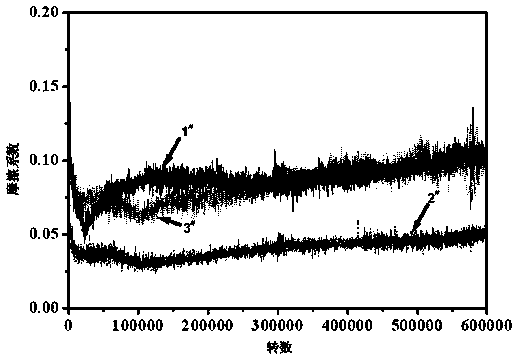

[0025] Performance of lubricating coating: Spray the dispersed lubricating coating on the surface of the part under compressed air (no oil) or compressed nitrogen (the surface of the part needs to be pre-degreased, derusted, sand blasted, ultrasonic and other surface treatment). The sprayed parts should be placed ...

Embodiment 2

[0027] Preparation of organic-inorganic composite resin: Weigh H 3 PO 4 35 g, CrO 3 7g, Al(OH) 3 14g, water 20g, put into a container and raise the temperature to 90~100°C and stir for 1~2 hours to form a homogeneous phase; when the temperature is lowered to below 40°C, add 24 g of PTFE emulsion and continue to stir for 4 hours, cool to room temperature and discharge;

[0028] Preparation of lubricating coating: Weigh 18 g of organic-inorganic composite resin, 12 g of molybdenum disulfide, 15 g of antimony trioxide, 4.5 g of cerium trifluoride, and 50.5 g of water. After mixing the raw materials used, they are evenly dispersed by ball milling to obtain a lubricating coating

[0029] Performance test of lubricating coating: Spray the dispersed lubricating coating on the surface of the part under compressed air (no oil) or compressed nitrogen (the surface of the part needs to be degreased, derusted, sand blasted, ultrasonic and other surface treatment in advance). The spr...

Embodiment 3

[0031] Preparation of organic-inorganic composite resin: Weigh H 3 PO 4 35 g, CrO 3 7g, Al(OH) 3 14g, water 24g, put into a container and raise the temperature to 90~100°C and stir for 1~2 hours to form a homogeneous phase; when the temperature drops below 40°C, add 20 g of FEP emulsion and continue stirring for 4 hours, then cool to room temperature and discharge;

[0032]Preparation of lubricating coating: Weigh 20 g of organic-inorganic composite resin, 14 g of molybdenum disulfide, 15 g of antimony trioxide, 3.5 g of cerium trifluoride, and 47.5 g of water. The raw materials used are mixed and dispersed uniformly by ball milling to obtain a lubricating coating;

[0033] Performance test of lubricating coating: Spray the dispersed lubricating coating on the surface of the part under compressed air (no oil) or compressed nitrogen (the surface of the part needs to be degreased, derusted, sand blasted, ultrasonic and other surface treatment in advance). The sprayed part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com