Cerium-zirconium composite oxide as well as preparation method and application thereof

A composite oxide, cerium oxide technology, applied in chemical instruments and methods, catalyst activation/preparation, separation methods, etc., can solve the problems of unsatisfactory practical application, low oxygen storage capacity of cerium zirconium composite oxide, etc. Oxygen storage capacity, improving oxygen storage performance, good oxygen storage and reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

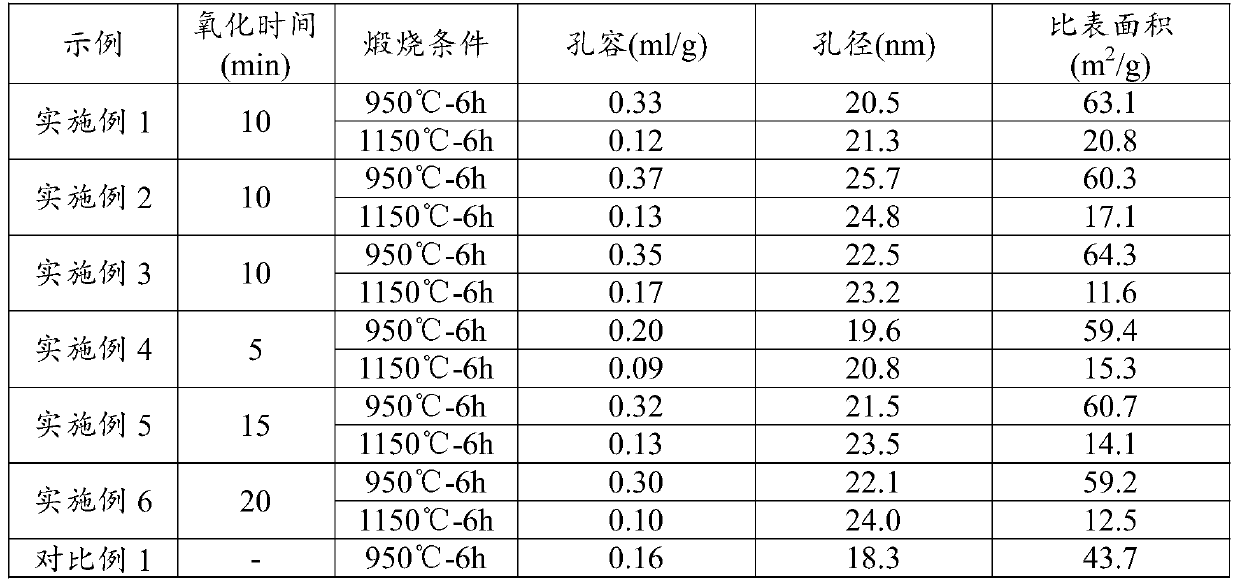

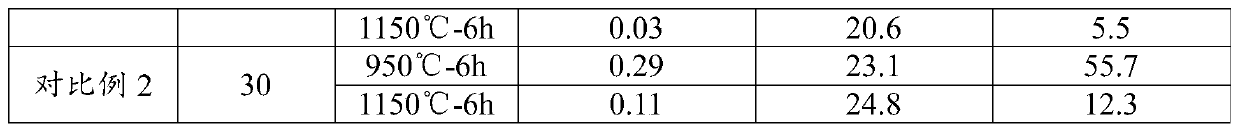

[0047] The invention provides a method for preparing a cerium-zirconium composite oxide, including the steps of preparing by hydrothermal method, specifically as follows:

[0048] S1, dissolving salts of cerium, zirconium, and rare earth metals respectively, with a total concentration of 20-160g / L;

[0049] S2, add an appropriate amount of 30% H to the above solution 2 o 2 , stirred and oxidized for 5-35min;

[0050] S3, drop an alkaline precipitating agent, the alkaline precipitating agent is one or more of ammonia water, sodium hydroxide, and amines, preferably ammonia water, and then adjust the pH of the solution to 1.5-2;

[0051] S4, introducing the above solution into a high-pressure reactor, and performing a high-temperature hydrolysis reaction at 120-220° C. for 10-20 hours;

[0052] S5, adding an alkaline precipitant dropwise to the precursor slurry obtained in S3 to adjust the pH to 8-10;

[0053] S6, introducing the precursor slurry obtained in S4 into an autocl...

Embodiment 1

[0057] Example 1 provides a cerium-zirconium composite oxide, which is prepared by the following method:

[0058] Take 473.5g of zirconium nitrate, dissolve it with 2000ml of deionized water until it becomes clear, and take another 16.3g of yttrium oxide, dissolve it with 53.2g of concentrated nitric acid, mix it with the above solution, add 434.4g of ammonium cerium nitrate and 84.9g of lanthanum nitrate, and stir until it becomes clear. Obtain solution A, then add 30% H in solution A with 1.5 times the molar amount of cerium 2 o 2 , stirred and oxidized for 10 minutes;

[0059] Adjust the pH of the oxidized solution A to 1.5-2 with ammonia water in a 50°C water bath, set the volume to 6400ml, and introduce it into a polytetrafluoroethylene-lined pressure melting bomb. Adjust the pH to about 9.5 with ammonia water to obtain slurry B;

[0060] Transfer the slurry B to a titanium kettle, and conduct a hydrothermal reaction at 180° C. for 10 h at a rotation speed of 200 r / min...

Embodiment 2

[0063] Example 2 provides a cerium-zirconium composite oxide, which is prepared by the following method:

[0064] Take 550.7g of zirconium nitrate, dissolve it with 2000ml of deionized water until it becomes clear, take another 39.9g of yttrium oxide, dissolve it with 102.0g of concentrated nitric acid and mix it with the above solution, then add 194.9g of ammonium cerium nitrate and 22.3g of lanthanum nitrate, and stir until it becomes clear , to obtain solution A, and then add 30% H with 1.5 times the molar amount of cerium to solution A 2 o 2 , stirred and oxidized for 10 minutes;

[0065] Adjust the pH of the oxidized solution A to 1.5-2 with ammonia water in a 50°C water bath, set the volume to 6400ml, and introduce it into a polytetrafluoroethylene-lined pressure melting bomb. Adjust the pH to about 9.5 with ammonia water to obtain slurry B;

[0066] Transfer the slurry B to a titanium kettle, and conduct a hydrothermal reaction at 180° C. for 10 h at a rotation speed...

PUM

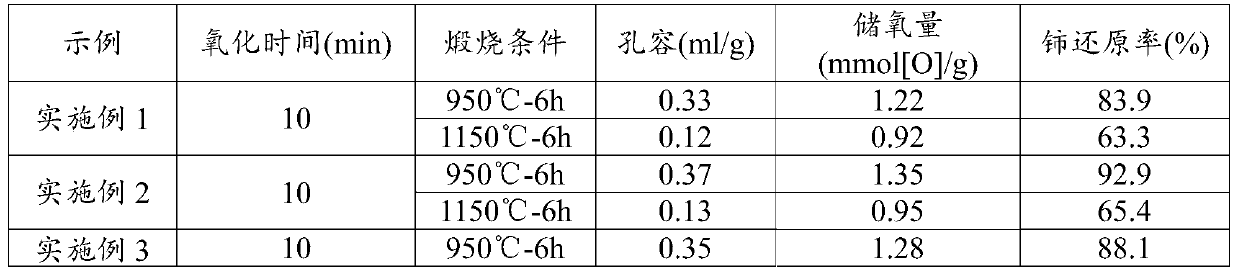

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com