A kind of preparation method of near-infrared enhanced room temperature gas sensing material

A gas sensing and near-infrared technology, applied in the field of nanomaterials, can solve the problems of difficult desorption of the detected gas, affecting the overall performance of the material, and long detection recovery time, so as to improve the gas sensing performance and improve the gas sensing sensitivity. , to achieve the effect of gas sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

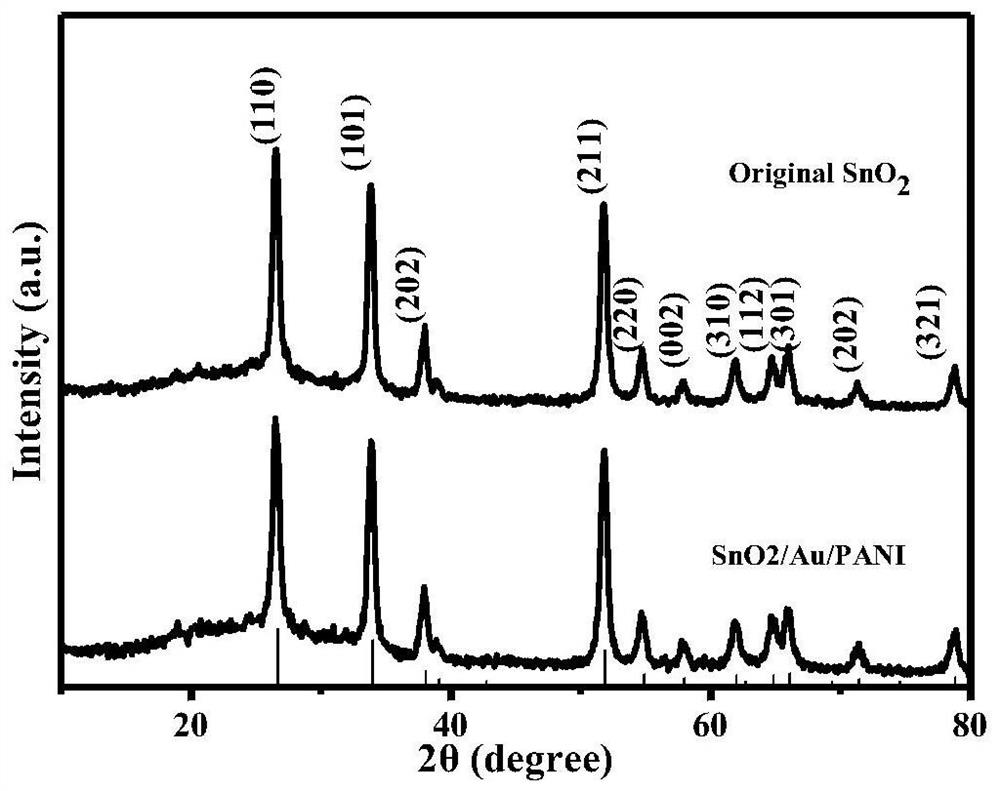

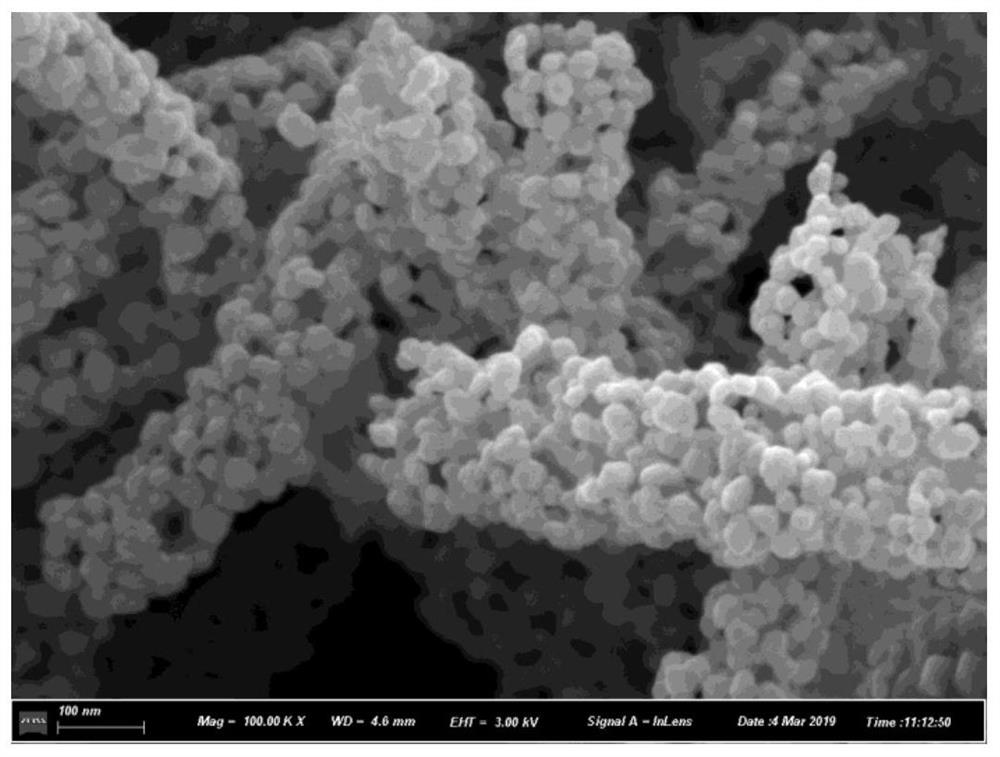

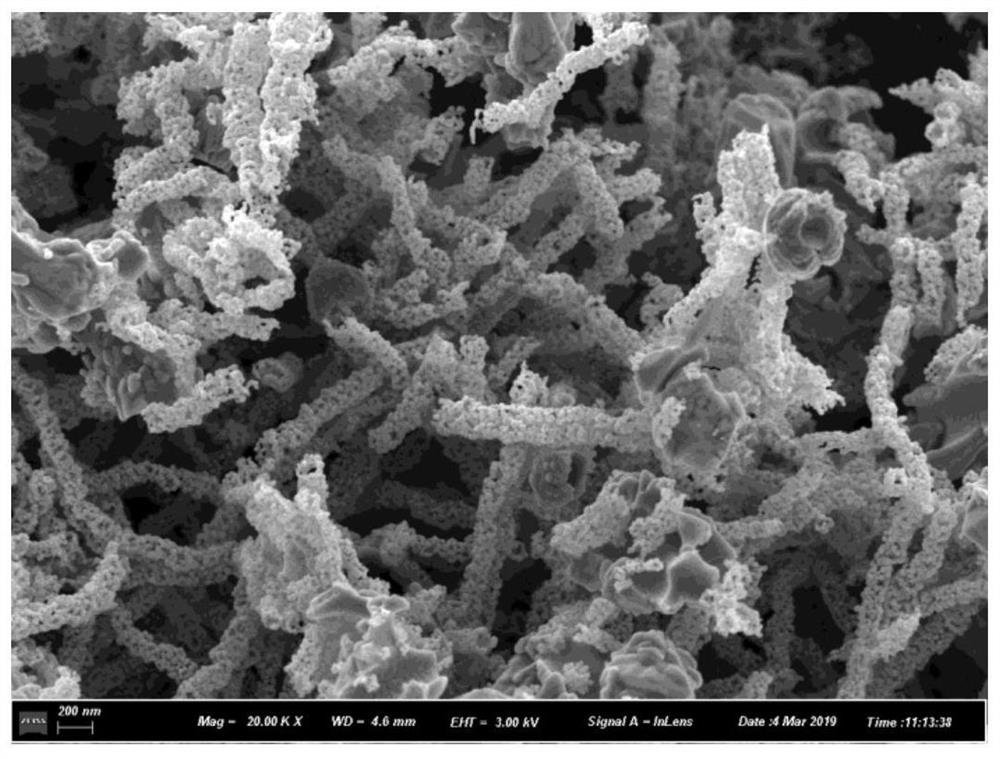

[0026] The preparation of a tin oxide porous nanotube containing oxygen vacancies is carried out as follows:

[0027] (1) Weigh 0.35g of tin chloride pentahydrate, 2.2g of N,N-dimethylformamide, and 2.2g of ethanol into the Erlenmeyer flask and stir to dissolve, then add 0.4g of PVP into it, stir for 12 hours, and prepare the precursor .

[0028] (2) Take the precursor solution and put it in the high-voltage electrospinning molding equipment, and use the high-voltage electrostatic molding technology to synthesize it. The precursor solution is put into a syringe pump with a needle of 0.8mm, and the high-voltage static electricity is set to 16KV, and the temperature is set to 60°C. Sol fibers; put the collected fibers in an oven with a temperature set at 80°C, and dry for 3 hours; finally put the fibers in a muffle furnace, heat up at a rate of 4°C / min, and roast at 600°C for 3 hours to obtain tin dioxide porous nanotubes.

[0029] (3) The tin dioxide porous nanotubes are plac...

Embodiment 2

[0035] The preparation of a tin oxide porous nanotube containing oxygen vacancies is carried out as follows:

[0036] (1) Weigh 0.33g of tin chloride pentahydrate, 2.0g of N,N-dimethylformamide, and 2.0g of ethanol into the Erlenmeyer flask and stir to dissolve, then add 0.3g of PVP into it, stir for 8 hours, and prepare the precursor .

[0037] (2) Take the precursor solution and put it in the high-voltage electrospinning molding equipment, and use the high-voltage electrostatic molding technology to synthesize it. The precursor solution is put into a syringe pump with a needle of 0.8mm, and the high-voltage static electricity is set to 12KV, and the temperature is set to 50°C. Sol fiber; put the collected fiber in an oven with a temperature set at 70°C, and dry it for 4 hours; finally put the fiber into a muffle furnace, heat up at a rate of 4°C / min, and bake it at 650°C for 2 hours to obtain tin dioxide porous nanotubes.

[0038] (3) The tin dioxide porous nanotubes are p...

Embodiment 3

[0043] The preparation of a tin oxide porous nanotube containing oxygen vacancies is carried out as follows:

[0044] (1) Weigh 0.37g of tin chloride pentahydrate, 2.4g of N,N-dimethylformamide, and 2.4g of ethanol into the Erlenmeyer flask and stir to dissolve, then add 0.5g of PVP into it, stir for 15h, and prepare the precursor .

[0045] (2) Take the precursor solution and put it in the high-voltage electrospinning molding equipment, and use the high-voltage electrostatic molding technology to synthesize it. The precursor solution is put into a syringe pump with a needle of 0.8mm. Sol fiber; put the collected fiber in an oven with a temperature set at 90°C, and dry it for 4 hours; finally put the fiber into a muffle furnace, heat up at a rate of 4°C / min, and roast at 650°C for 3 hours to obtain tin dioxide porous nanotubes.

[0046] (3) The tin dioxide porous nanotubes are placed in a hydrogen plasma tubular induction furnace, the hydrogen flow rate is set to 50ml / min, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com