Liquid ceramic waterproof anti-corrosion novel material for water park and swimming pool and preparation method of liquid ceramic waterproof anti-corrosion novel material

A new material and swimming pool technology, applied in anti-corrosion coatings, fire-proof coatings, starch coatings, etc., can solve the problems of insignificant waterproof and wear-resistant effects, uneven quality, and environmental pollution, and achieve good mechanical properties and convenient construction and operation , no VOC emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

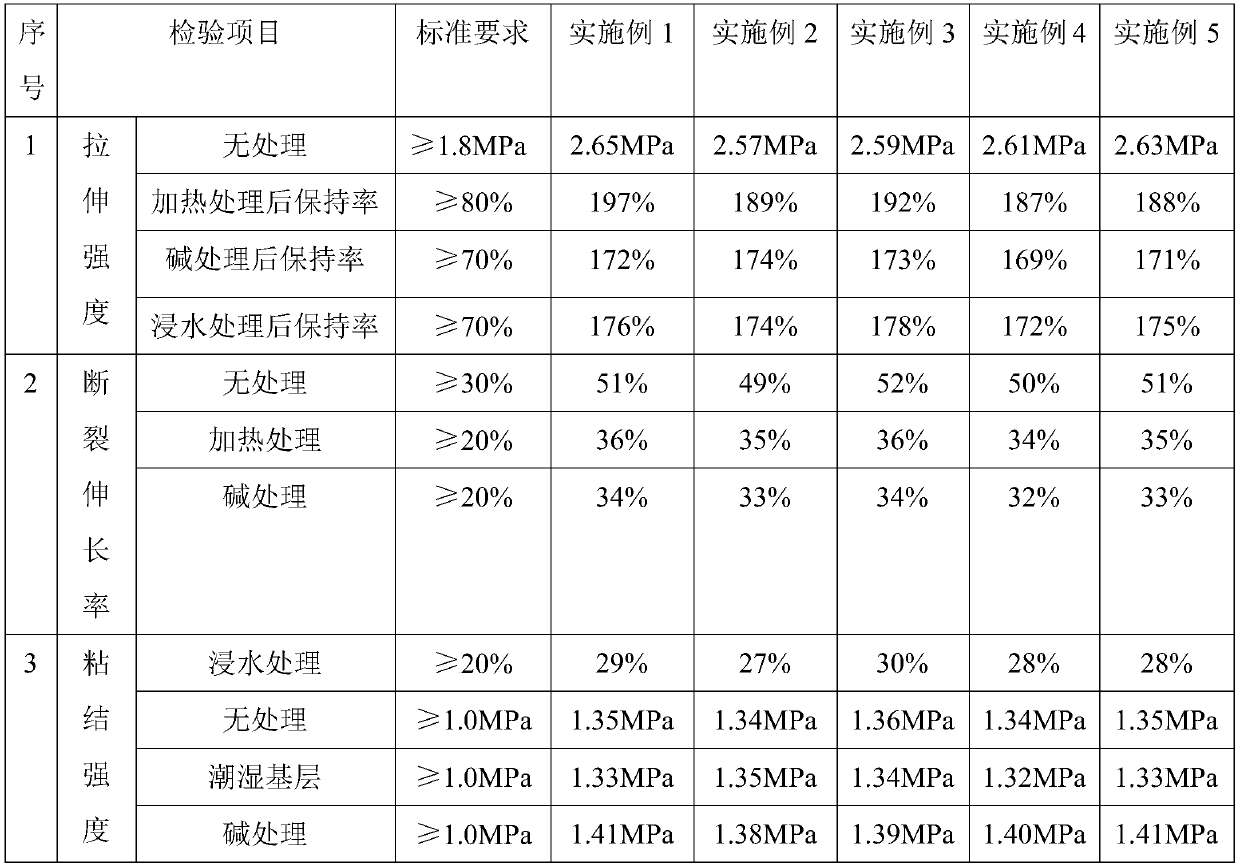

Examples

Embodiment 1

[0025] The liquid ceramic waterproof and anti-corrosion new material for water parks and swimming pools is composed of the following raw materials in parts by weight: 30 parts of epoxy resin, 30 parts of bismaleimide resin, 35 parts of allyl compound, 5 parts of nano-ceramic powder, 3 parts of variable agent, 10 parts of environmentally friendly pigment, 60 parts of inorganic filler, 50 parts of curing agent, 5 parts of white corundum micropowder, 15 parts of glutinous rice flour, 2 parts of liquid silicone rubber, 10 parts of cellulose ether, 2 parts of explosion-proof fiber, stone powder 5 parts, 10 parts of polyacrylate, 5 parts of water-based polyurethane, 5 parts of silicone, 6 parts of dispersant, 0.5 parts of water reducing agent, 1.5 parts of leveling agent, 2 parts of preservative, 2 parts of stabilizer; the environmental protection type The pigment is composed of the following raw materials in parts by weight: 10 parts of pigment, 8 parts of polyvinyl acetate emulsion...

Embodiment 2

[0033] The liquid ceramic waterproof and anti-corrosion new material for water parks and swimming pools is composed of the following raw materials in parts by weight: 35 parts of epoxy resin, 35 parts of bismaleimide resin, 38 parts of allyl compound, 6 parts of nano-ceramic powder, 3.5 parts of variable agent, 11 parts of environment-friendly pigment, 65 parts of inorganic filler, 60 parts of curing agent, 6 parts of white corundum powder, 16 parts of glutinous rice flour, 3 parts of liquid silicone rubber, 12 parts of cellulose ether, 2.5 parts of explosion-proof fiber, stone powder 5.5 parts, 12 parts of polyacrylate, 8 parts of water-based polyurethane, 8 parts of silicone, 6.5 parts of dispersant, 0.8 parts of water reducing agent, 1.8 parts of leveling agent, 2.5 parts of preservative, 2.5 parts of stabilizer; the environmental protection type The pigment is composed of the following raw materials in parts by weight: 11 parts of pigment, 8.5 parts of polyvinyl acetate emu...

Embodiment 3

[0041] The liquid ceramic waterproof and anti-corrosion new material for water parks and swimming pools is composed of the following raw materials in parts by weight: 40 parts of epoxy resin, 40 parts of bismaleimide resin, 40 parts of allyl compound, 7 parts of nano-ceramic powder, 4 parts of variable agent, 12 parts of environmentally friendly pigment, 70 parts of inorganic filler, 70 parts of curing agent, 8 parts of white corundum micropowder, 18 parts of glutinous rice flour, 3.5 parts of liquid silicone rubber, 15 parts of cellulose ether, 3 parts of explosion-proof fiber, stone powder 6 parts, 15 parts of polyacrylate, 10 parts of water-based polyurethane, 10 parts of silicone, 7 parts of dispersant, 1 part of water reducer, 2 parts of leveling agent, 3 parts of preservative, 3 parts of stabilizer; the environmental protection type The pigment is composed of the following raw materials in parts by weight: 12 parts of pigment, 9 parts of polyvinyl acetate emulsion, 6 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com