Nickel-based catalyst used for preparation of hydrogenated petroleum resin as well as preparation method and application of catalyst

A technology for hydrogenating petroleum resins and nickel-based catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the influence of catalyst life and reduce catalyst hydrogenation activity , irreversible deactivation and other problems, to achieve the effect of inhibiting the reduction of softening point, high industrial application value, and excellent hydrogenation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

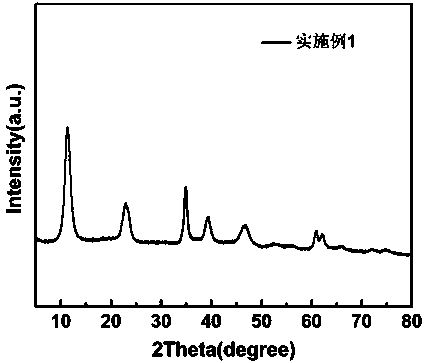

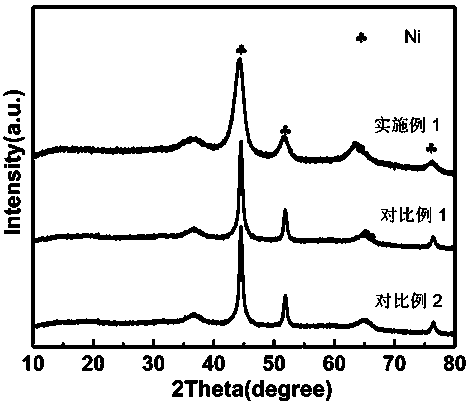

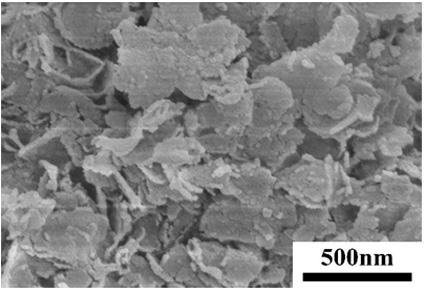

[0041] 0.01 mol Ni(NO 3 ) 2 •6H 2 O (molecular weight 290.81), 0.05 mol Mg(NO 3 ) 2 •6H 2 O (molecular weight 256.41), 0.05mol Al(NO 3 ) 3 •9H 2 O (molecular weight 375.13), 0.001 mol La(NO 3 ) 3 •9H 2 O (molecular weight 487.05) and 0.405 mol urea (molecular weight 60.06) were added to 100 g of deionized water, stirred evenly, transferred to a stainless steel reactor with a polytetrafluoroethylene liner, and then placed in a rotary oven at 95 °C for dynamic crystallization. 6 h, after static aging for 6 h, cool to room temperature, vacuum filter, wash the precipitate, and dry the precipitate in an oven at 70 °C to constant weight to obtain the quaternary nickel-magnesium-aluminum-lanthanum hydrotalcite NiMgLaAl-LDH, and then the obtained quaternary The nickel-magnesium-aluminum hydrotalcite was placed in a muffle furnace, raised from room temperature to 500 °C at a rate of 5 °C / min, and calcined for 6 h to obtain a composite metal oxide precursor, which was placed i...

Embodiment 2

[0044] 0.025 mol Ni(NO 3 ) 2 •6H 2 O, 0.05 mol Mg(NO 3 ) 2 •6H 2 O, 0.05mol Al(NO 3 ) 3 •9H 2 O , 0.002 mol Cu(NO 3 ) 2 •3H 2 O (molecular weight 235.56) and 0.45mol urea were added to 120g deionized water, stirred evenly, transferred to a stainless steel reactor with a polytetrafluoroethylene liner, and then placed in a rotary oven for dynamic crystallization at 105 °C for 12 h. After static aging for 6 h, cool to room temperature, vacuum filter, wash the precipitate, and dry the precipitate in an oven at 70 °C to constant weight to obtain light green quaternary hydrotalcite NiMgAlCu-LDH, and then place the obtained quaternary hydrotalcite in a horse In a Furnace, the temperature was increased from room temperature to 400 °C at a rate of 5 °C / min, and roasted for 6 h to obtain a composite metal oxide precursor, which was placed in a tube furnace under a hydrogen atmosphere at 750 °C (flow rate kept Reduction at 50-100 ml / min) for 6 h, then cooled to room temperatur...

Embodiment 3

[0047] 0.01 mol Ni(NO 3 ) 2 •6H 2 O, 0.05 mol Mg(NO 3 ) 2 •6H 2 O, 0.05mol Al(NO 3 ) 3 •9H 2 O , 0.002mol Cu(NO 3 ) 2 •3H 2 O and 0.405 mol urea were added to 100 g of deionized water, stirred evenly, transferred to a stainless steel reactor with a polytetrafluoroethylene liner, and then placed in a rotary oven for dynamic crystallization at 115 °C for 18 h, and after static aging for 6 h , cooled to room temperature, vacuum filtered, washed the precipitate, and dried the precipitate in an oven at 70 °C to constant weight to obtain light green quaternary hydrotalcite NiMgAlCu-LDH, and then place the obtained quaternary hydrotalcite in a muffle furnace to The rate of 5 ℃ / min was increased from room temperature to 600 ℃, and calcined for 6 h to obtain a composite metal oxide precursor, which was placed in a tube furnace under a hydrogen atmosphere of 850 ℃ (the flow rate was kept at 50-100 ml / min) reduction for 6 h, then cooled to room temperature, formed by mechanic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com