High-valent metal fluorination catalyst and preparation method and application thereof

A technology of fluorination catalysts and high-valent metal ions, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve human health damage, difficulty in circulation, and environmental pollution And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

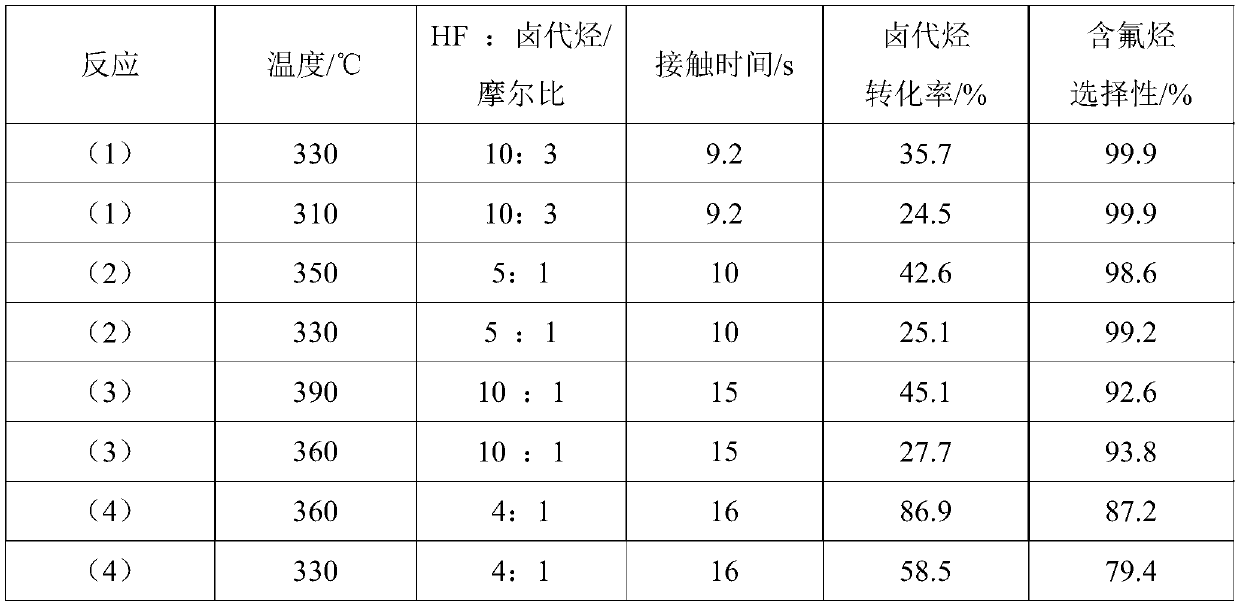

Embodiment 1

[0040] According to the composition of 100% and 0% of chromium ions and auxiliary elements, dissolve chromium trichloride in water, drop concentrated ammonia water for precipitation, adjust the pH value to 7.5, then wash with water, filter, and dry in an oven at 80°C for 36 hour, the resulting solid was pulverized, pressed into tablets to obtain a catalyst precursor, and 10 mL of the catalyst precursor was packed into a tube reactor made of Monel material with an inner diameter of 1 / 2 inch and a length of 30 cm, and nitrogen gas was fed into it for roasting at 450 ° C. 8 hours, nitrogen air velocity is 200h -1 , and then lower the temperature to 300°C, and at the same time pass a mixed gas composed of hydrogen fluoride and nitrogen with a mass ratio of 1:2, and the total space velocity of the gas is 220h -1 , activated for 24 hours; then the temperature was raised to 375°C, and at the same time, a mixed gas composed of nitrogen and nitrogen trifluoride with a mass ratio of 10:...

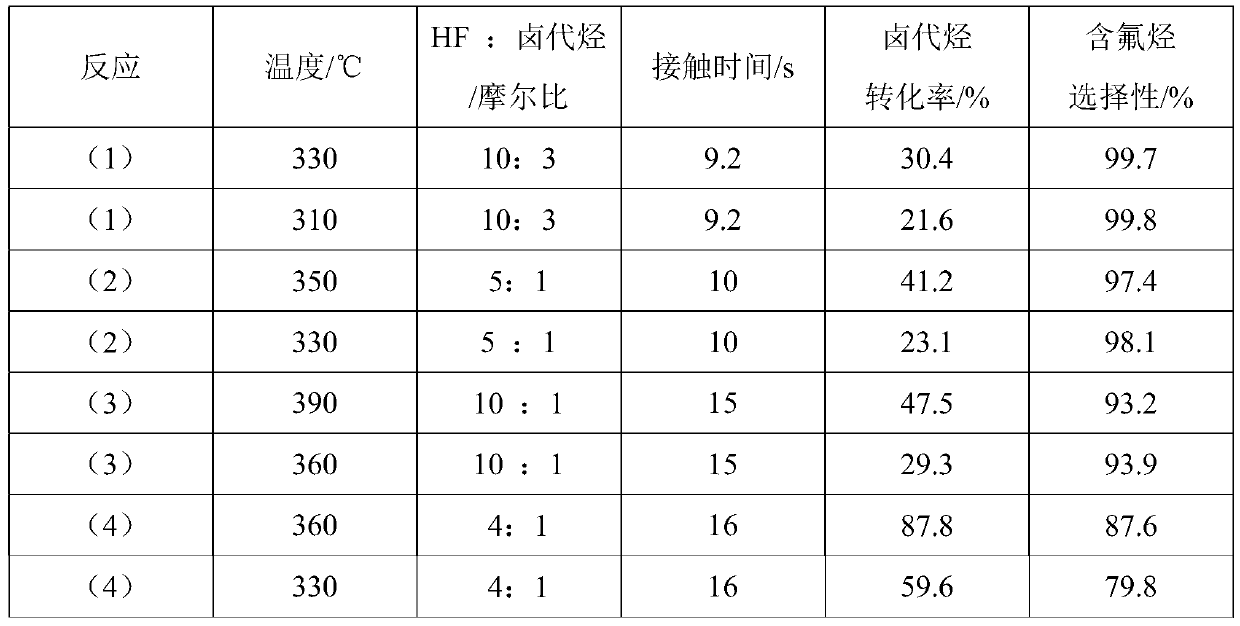

Embodiment 2

[0042] The catalyst preparation process is basically the same as in Example 1, except that the percentage composition of chromium ions and zinc elements is 90% and 10%.

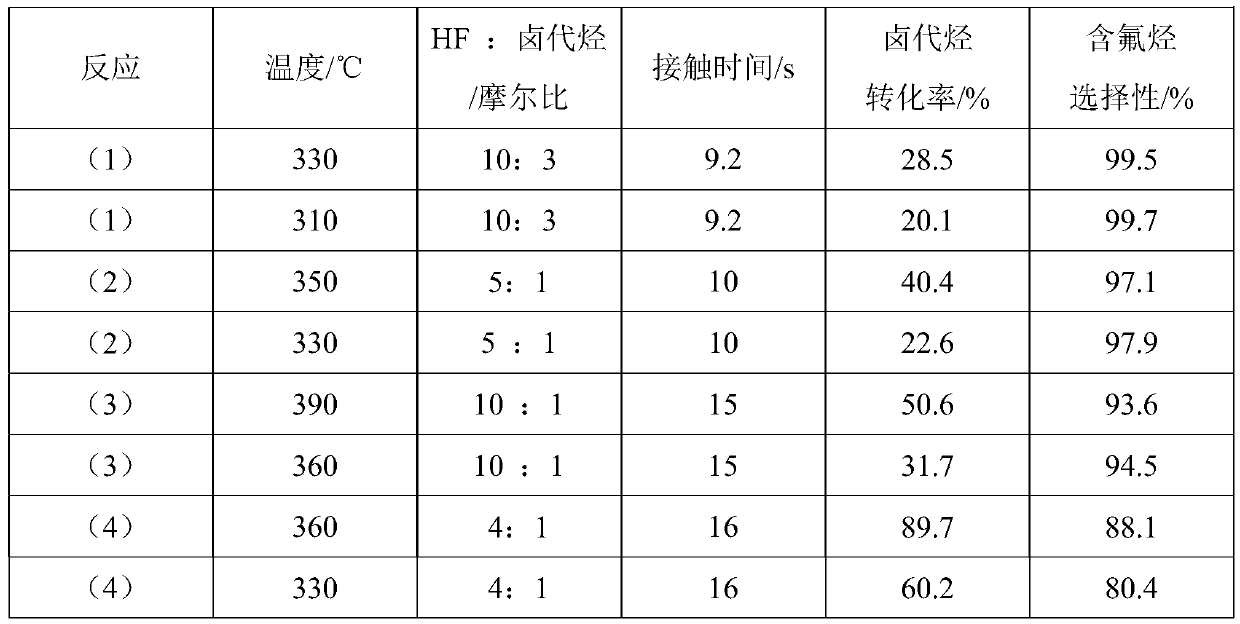

Embodiment 3

[0044] The catalyst preparation process is basically the same as in Example 1, except that the percentage composition of chromium ions and cobalt elements is 90% and 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com