All-solid composite polymer solid electrolyte and preparation method thereof

A solid electrolyte and matrix technology, applied in electrolytes, circuits, electrical components, etc., can solve problems affecting battery current density and cycle performance, low ionic conductivity, poor interface stability, etc., to achieve improved conductivity, high conductivity, The effect of low crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation of polyperfluorohexyl ethyl methacrylate

[0039] According to azobisisobutyronitrile: polyperfluorohexyl ethyl methacrylate = 1:99, feed into the reaction kettle separately, dissolve in DMF solution, and raise the temperature to 70°C, nitrogen protection, and continue the reaction for seven Hours; after the reaction is over, the product solution is concentrated, separated out using n-hexane solution, and washed several times to obtain polyperfluorohexylethyl methacrylate, and then dried at 50-60°C for future use.

Embodiment 2

[0040] Example 2 Preparation of solid electrolyte matrix S1

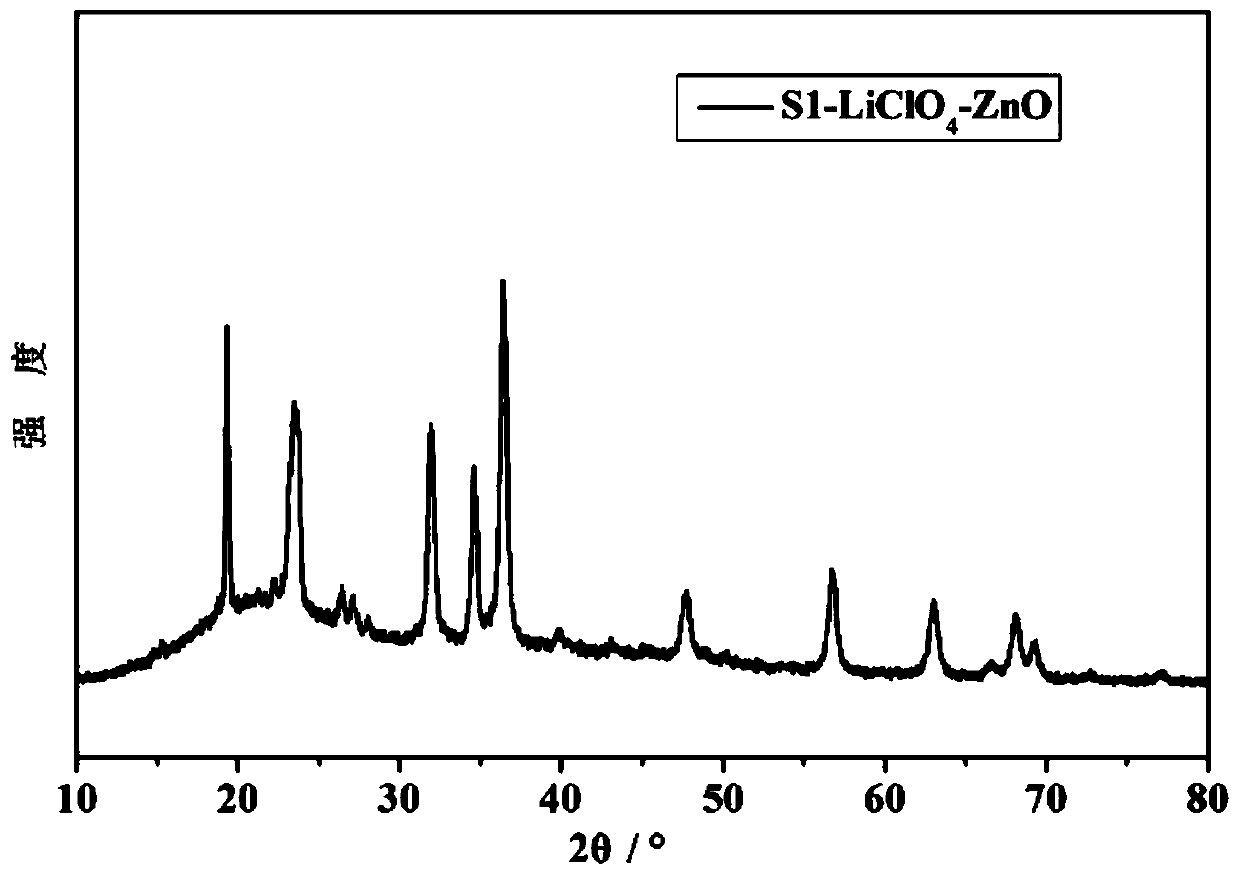

[0041] Take an appropriate amount of PEO polymer (polyethylene oxide) and polyperfluorohexylethyl methacrylate and dry it in vacuum at 60°C for 24h, weigh 5.28g of PEO polymer and 2.64g of polyperfluorohexylethylmethacrylate Acrylate poly(PEO polymer: polyperfluorohexylethyl methacrylate poly=10:5), add an appropriate amount of acetonitrile, and stir magnetically at 60°C until uniform to obtain a solid electrolyte matrix S1. In order to further verify the formation of solid electrolyte matrix S1, the XSD diagrams of the blended product and the two raw materials were compared and analyzed. The comparison results showed that a new polymer phase, namely solid electrolyte matrix S1, was formed after blending.

Embodiment 3

[0042] Example 3 Preparation of solid electrolyte matrix S2

[0043]Take an appropriate amount of PEO polymer (polyethylene oxide) and polyperfluorohexylethyl methacrylate and dry it in vacuum at 60°C for 24h, weigh 5.28g of PEO polymer and 5.28g of polyperfluorohexylethyl methacrylate Acrylate poly(PEO polymer: polyperfluorohexylethyl methacrylate poly=10:10), add an appropriate amount of acetonitrile, and stir magnetically at 70°C until uniform to obtain a solid electrolyte matrix S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com