Aluminum alloy for hydrogen production by hydrolysis and method for improving aluminum alloy hydrogen production rate

A technology for producing hydrogen and aluminum alloys by hydrolysis, which is applied in the field of hydrogen production from aluminum alloys. It can solve problems such as unsatisfactory hydrogen production performance, large demand for metal In, and insufficient transportation and storage, so as to improve hydrogen production performance and reduce energy consumption. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0035] Preparation of Al-Ga-In-Sn-Zn Quinary Alloy

[0036] (1) The alloy composition is shown in Table 1:

[0037]The alloy element composition mass percent (wt%) of table 1 embodiment 1-4

[0038]

[0039] (2) Preparation process:

[0040] According to the content ratio of each metal element in the aluminum alloy given in Table 1, each metal raw material is weighed, the purity of the raw material is ≥99wt%, and the weighed metal is placed in a high-temperature furnace under nitrogen protection, at 800 ° C. Sintering is carried out and the temperature is maintained at 800° C. for one hour. Stir and cast after heat preservation, cool under natural conditions after casting, and pack after cooling.

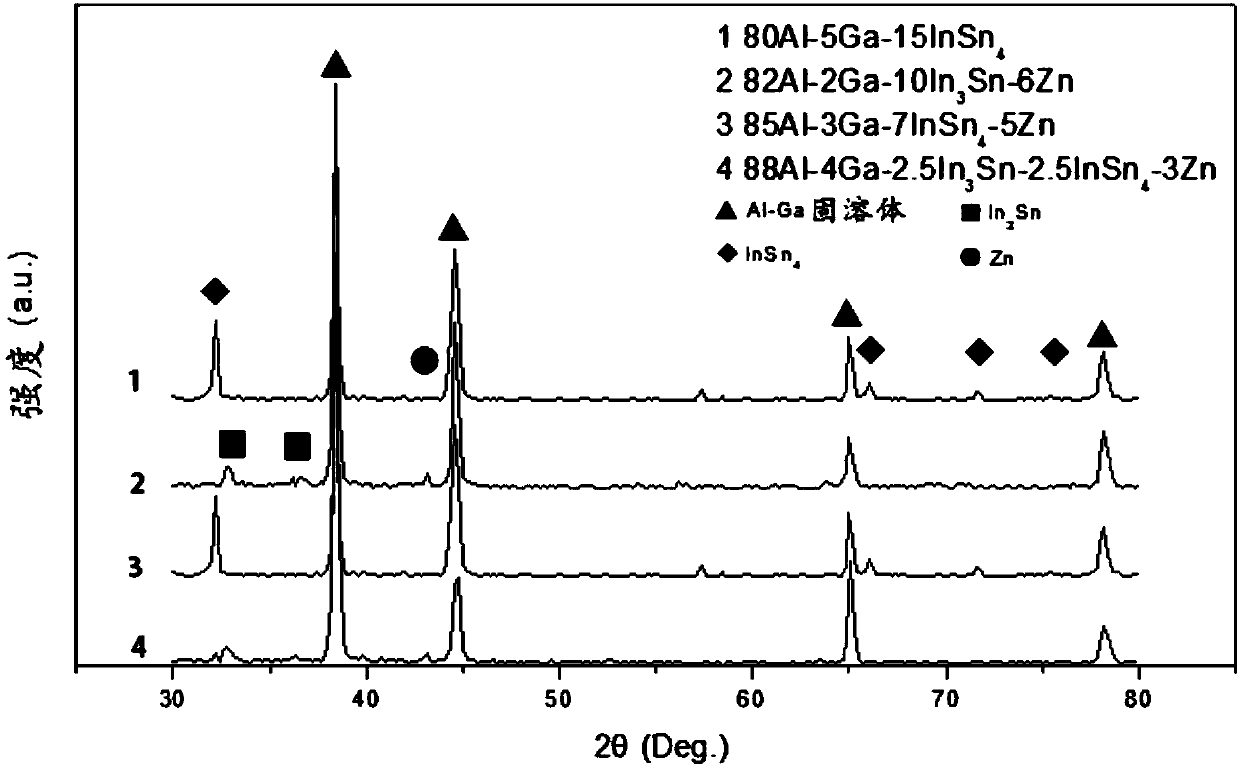

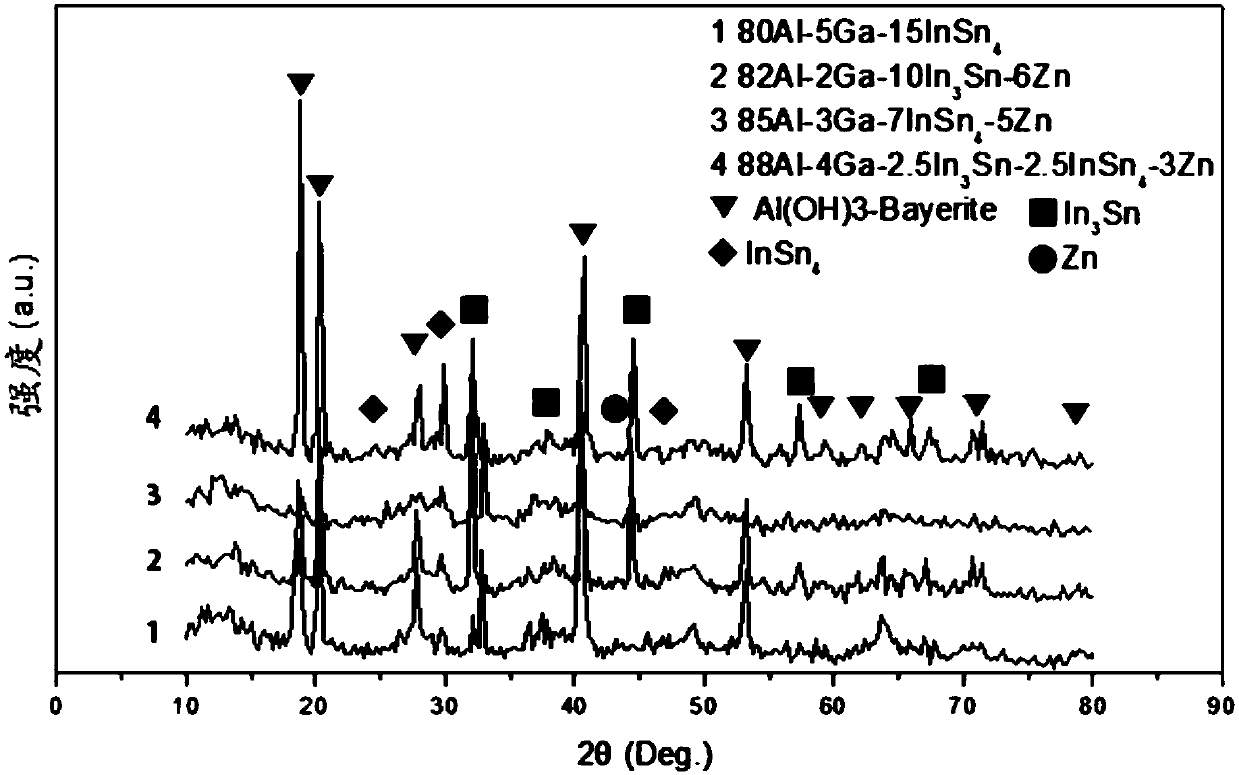

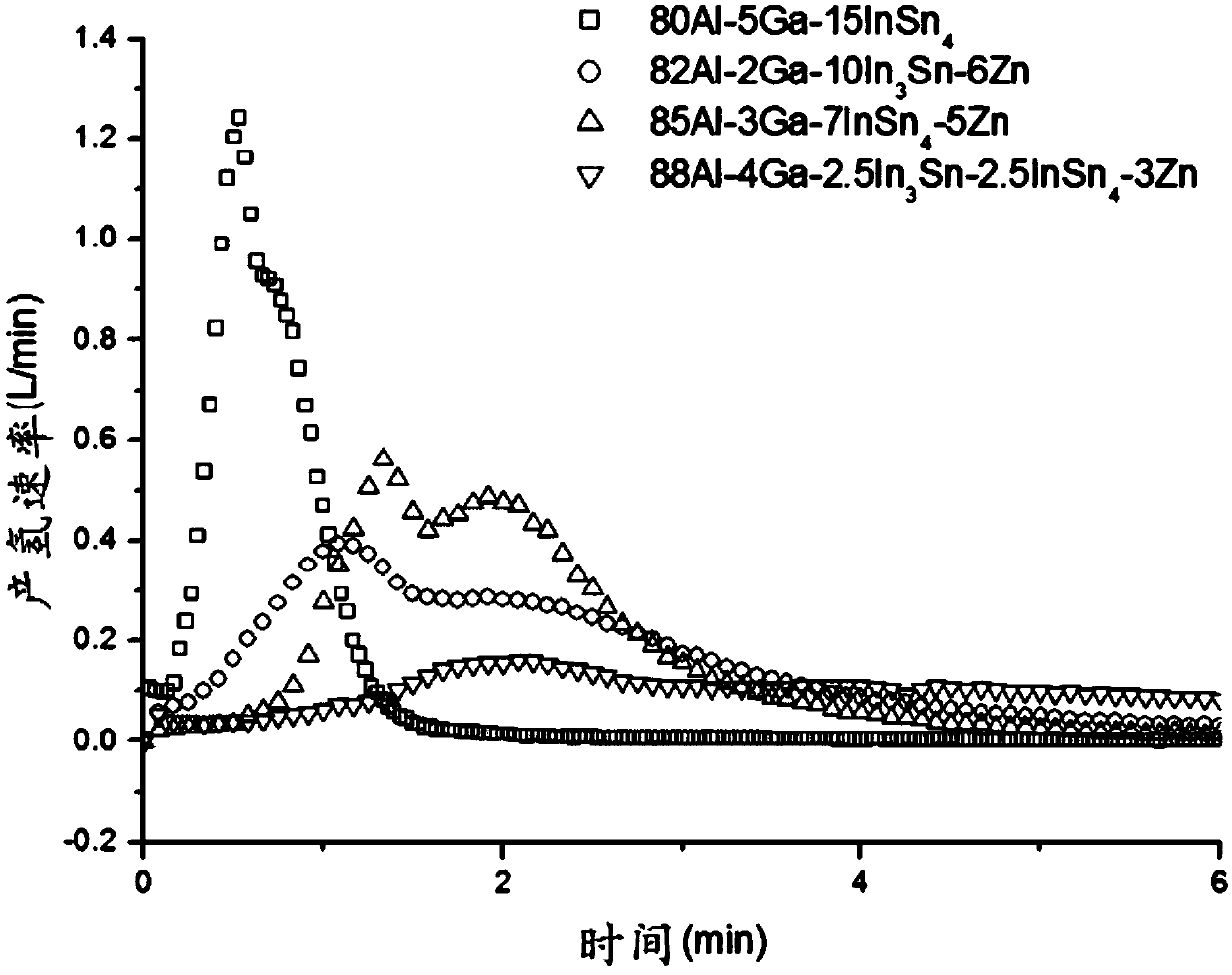

[0041] Among them, the alloys prepared in Examples 1-4 and the products after the hydrolysis reaction were characterized by XRD. For details, please refer to figure 1 with figure 2 ; by the figure 1 with 2 It can be seen that the phase of the alloy obtained in Examples 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com