Sulfone-containing epoxy resin and synthesis method thereof

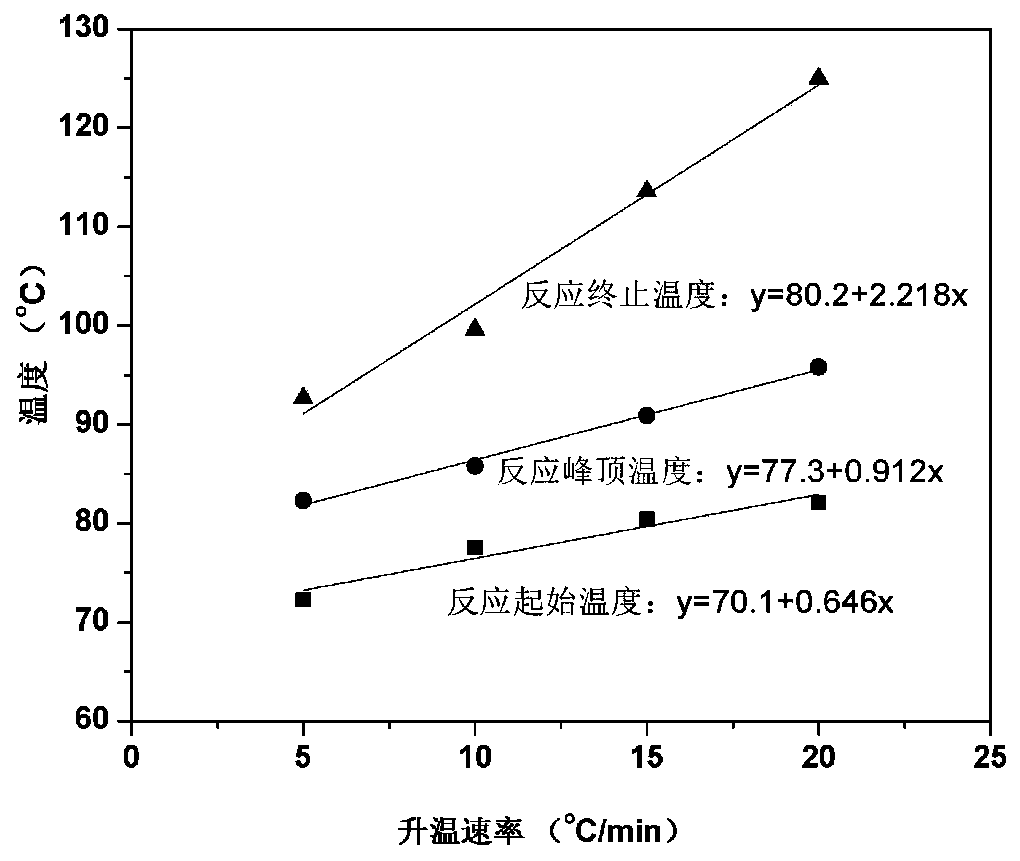

An epoxy resin and a technology for a synthesis method are applied in the field of epoxy resin preparation to achieve the effects of improving fracture strength and toughness, cheap and easy-to-obtain raw materials, and improving reaction activation energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

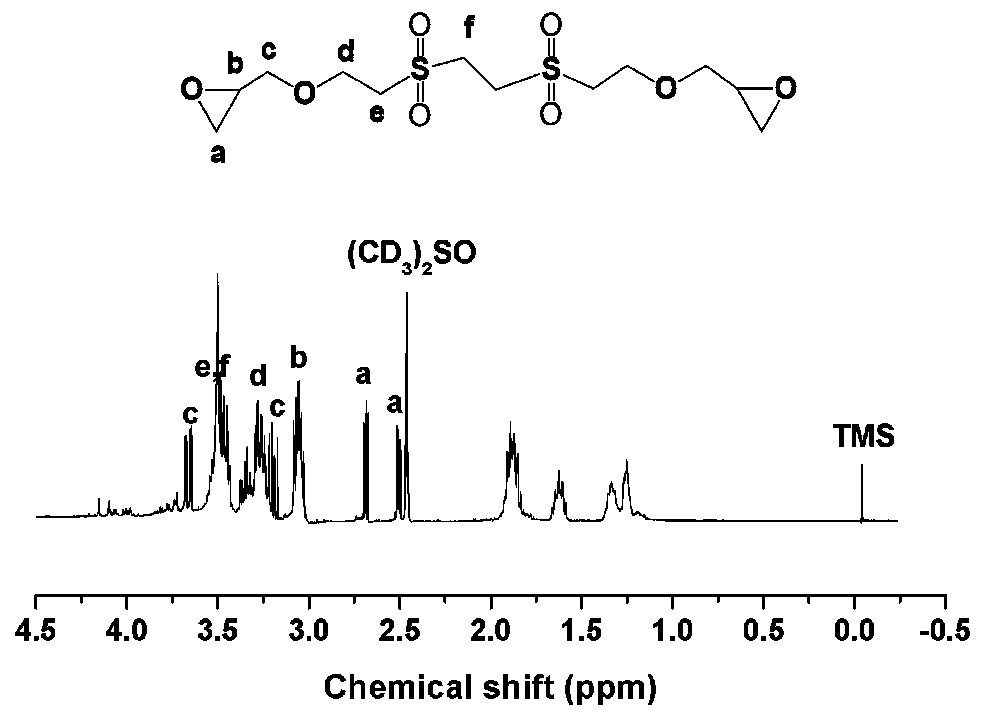

[0039] A synthetic method containing sulfone-based epoxy resin, comprising the following steps;

[0040] The raw material allyl glycidyl ether and 1,2-ethanedithiol are put into the reactor according to the molar ratio of 2:1, and benzoin dimethyl ether (accounting for the raw material allyl glycidyl ether and 1,2 -5% of the total mass of ethanedithiol) and 1,4-dioxane (accounting for 50% of the total mass of allyl glycidyl ether and 1,2-ethanedithiol), and at 3000mW / cm 2 Under the conditions of ultraviolet light irradiation and stirring, react in an ice-water bath for 1.0 hour; after the reaction, remove the solvent (1,4-dioxane) in a rotary evaporator to obtain the product;

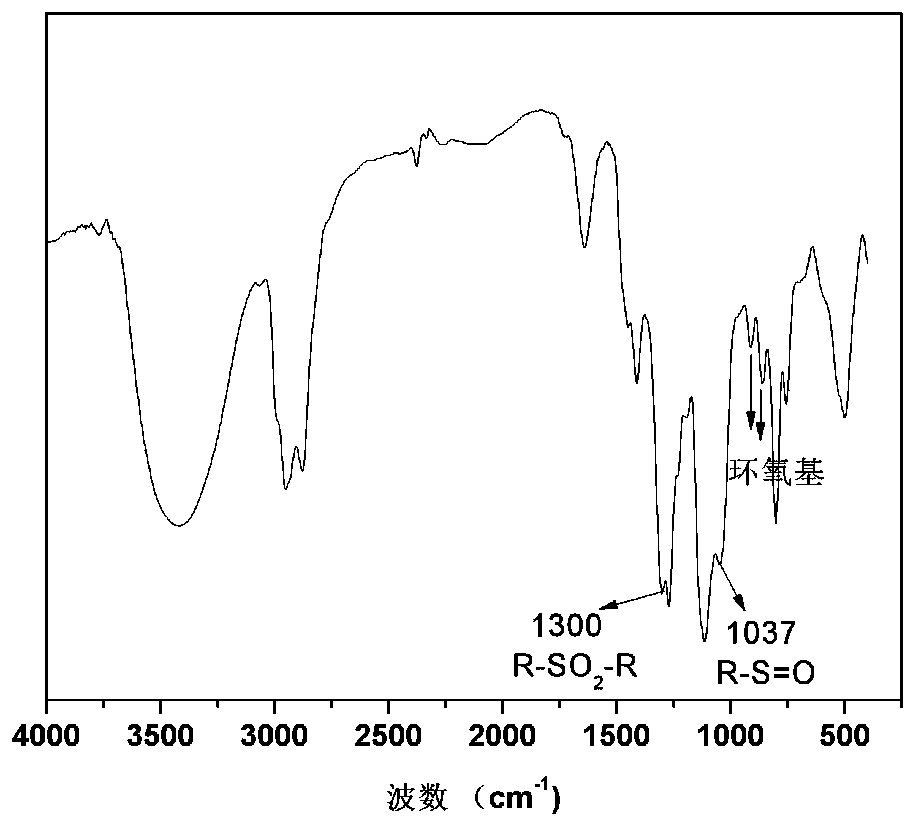

[0041]The obtained product was dissolved in methanol of 10 times its mass, and a concentration of 30% H 2 o 2 (The number of moles of the active ingredient is 3 times the number of moles of the product) and sodium tungstate dihydrate accounting for 1% of the product mass, reacted at room temperature a...

Embodiment 2

[0055] A kind of synthetic method containing sulfone group epoxy resin, comprises the following steps;

[0056] Put the raw material allyl glycidyl ether and 1,3-propanedithiol in a molar ratio of 2.1:1 into the reactor, and add 2-hydroxy-1-[4-(2-hydroxyethoxy) Phenyl]-2-methyl-1-propanone (accounting for 3% of the total mass of the raw material allyl glycidyl ether and 1,3-propanedithiol) and tetrahydrofuran (accounting for the raw material allyl glycidyl ether and 1, 70% of the total mass of 3-propanedithiol), and at 1500mW / cm 2 Under ultraviolet light irradiation and stirring conditions, react in an ice-water bath for 4.5 hours; after the reaction, remove the solvent (tetrahydrofuran) in a rotary evaporator to obtain the reaction product;

[0057] The obtained product was dissolved in 1,4-dioxane (20 times the mass of the product), added peracetic acid (3 times the molar mass of the product) and magnesium sulfate (3% of the mass of the product), and reacted at room tempera...

Embodiment 3

[0065] A kind of synthetic method containing sulfone group epoxy resin, comprises the following steps;

[0066] The raw material allyl glycidyl ether and 1,5-pentanedithiol are put into the reactor at a molar ratio of 1.9:1, and 2,2-dimethyl-α-hydroxyacetophenone (accounting for the raw material 1% of the total mass of allyl glycidyl ether and 1,5-pentanedithiol) and N,N-dimethylformamide (accounting for 1% of the total mass of raw material glycidyl ether and 1,5-pentanedithiol 80%), and at 1500mW / cm 2 Under the conditions of ultraviolet light irradiation and stirring, react in ice-water bath for 8 hours; after the reaction, remove the solvent in a rotary evaporator to obtain the product;

[0067] The product obtained is dissolved in methyl ethyl ketone (15 times of the product mass), and trifluoroacetic acid (10 times of the product molar number) and zinc chloride (1%-3% of the product mass) are added, at room temperature and reflux temperature After reacting for 3 hours, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com