Non-precious metal supported catalyst, preparation method and use thereof

A technology for supporting catalysts and non-precious metals, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of easy loss of active components of catalysts, and achieve enhanced possibility and ultra-high loading capacity , not easy to lose the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) preparation of catalyst, concrete steps are as follows:

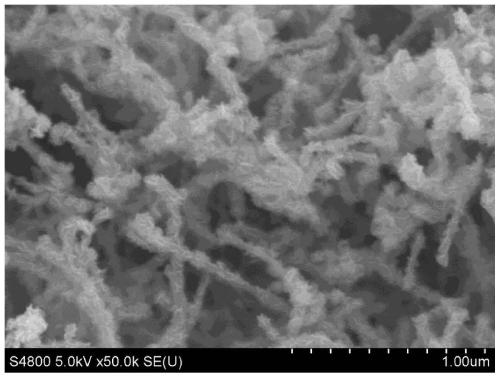

[0044] The mass fraction is 10% ordinary carbon nanotubes (outer diameter 10-20nm, length 0.5-20μm) are added in the concentrated nitric acid of 10mol / L, heated and refluxed at 80 ℃ for 12 hours, then washed with water until the supernatant pH > 4 and Dry at 100°C for 24h. Then add 2wt% of the above-mentioned modified carbon nanotubes in water, add 1wt% polyoxyethylene octyl phenyl ether at the same time, ultrasonically prepare the carbon nanotube dispersion, take 40mL of the above-mentioned carbon nanotube dispersion, stir and disperse in 760mL Add 5.72 grams of ammonium molybdate, 2.33 grams of nickel nitrate, 15.52 grams of anhydrous citric acid, and 9.14 grams of thiourea into the water at the same time. After mixing well, transfer to 200°C for hydrothermal treatment for 24 hours, then filter the obtained sample and vacuum at 60°C (vacuum degree is 0.1 atmospheric pressure) and dried for 48h to obtain th...

Embodiment 2-5

[0047] (1) The preparation concrete steps of embodiment 2-5 catalyst are as follows:

Embodiment 2

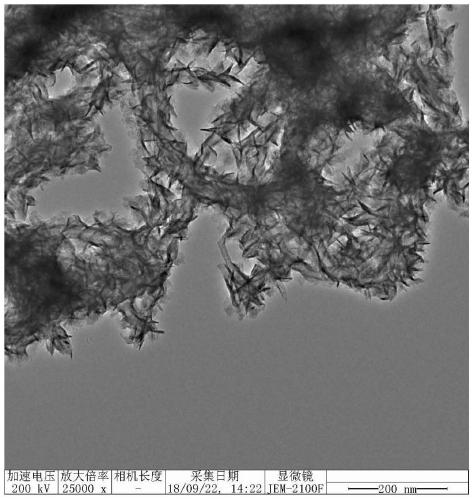

[0048] Example 2 Catalyst NiMoS / SWCNTs (SWCNTs are single-walled carbon nanotubes) preparation: add single-walled carbon nanotubes (outer diameter 1-2 nm, length 5-30 μm) with a mass fraction of 10% to 10 mol / L concentrated nitric acid and 10 mol / L concentrated sulfuric acid (v / v=3), heated to reflux at 80°C for 12h, washed with water until the supernatant had a pH>4, and dried at 100°C for 24h. Add the above-mentioned 2wt% modified carbon nanotubes and 1wt% polyoxyethylene octyl phenyl ether into water, and obtain a carbon nanotube dispersion after ultrasonication for 5 hours. Take 40mL of the carbon nanotube dispersion, stir and disperse it in 760mL of water, add 5.72 grams of ammonium molybdate, 2.33 grams of nickel nitrate, 15.52 grams of anhydrous citric acid, and 9.14 grams of thiourea. hours, then filtered and washed until the supernatant was colorless, and dried in a vacuum oven at 80°C (vacuum degree of 0.1 atmosphere) for 48 hours to obtain the above-mentioned sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com