A kind of rubidium, cerium co-doped bismuth calcium niobate base high temperature piezoelectric ceramics and preparation method thereof

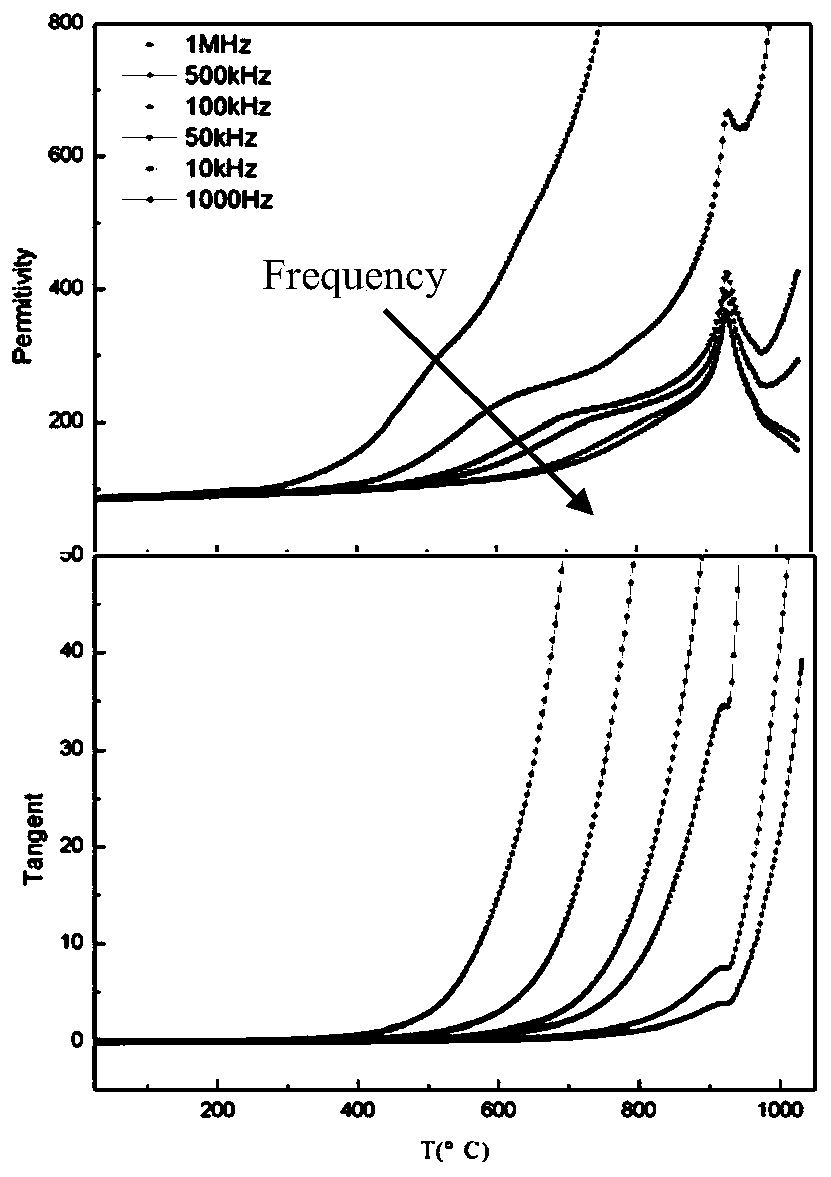

A calcium bismuth niobate-based, high-temperature piezoelectric technology, applied in the field of electronic ceramics and piezoelectric devices, can solve the problems of low piezoelectric performance and high Curie temperature, and achieve improved piezoelectric coefficient, high Curie temperature, and high temperature resistivity. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

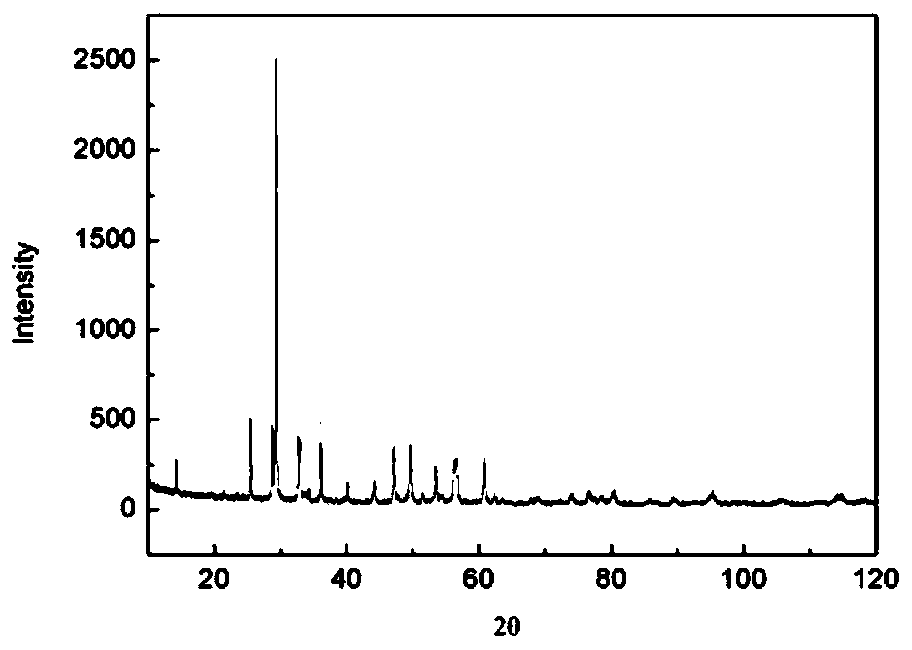

Method used

Image

Examples

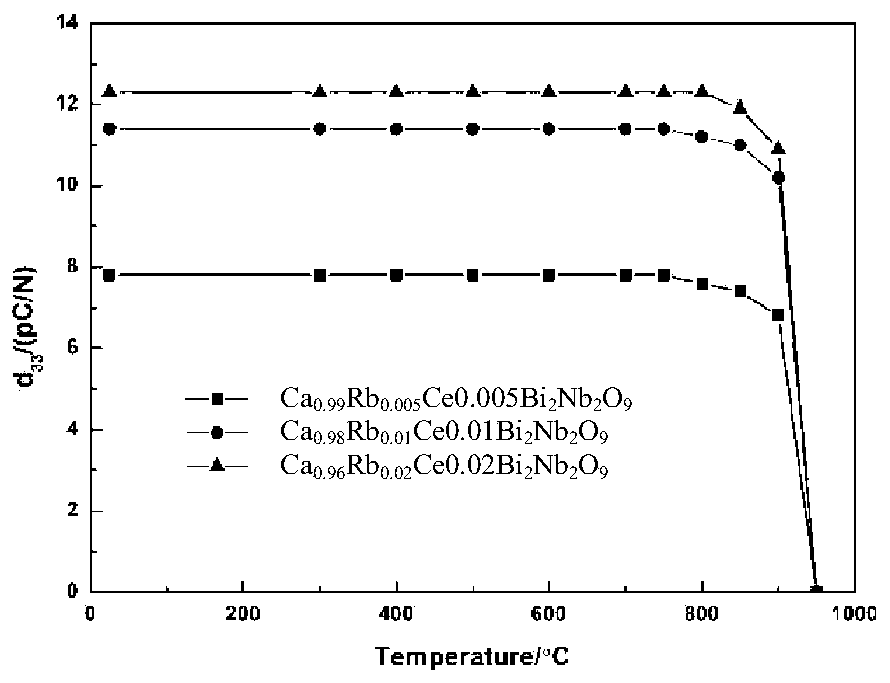

Embodiment 1

[0034] The preparation method of the rubidium and cerium co-doped bismuth calcium niobate-based high-temperature piezoelectric ceramics in this embodiment comprises the following steps:

[0035] (1) The raw material is according to the general formula Ca 1-x-y Rb x Ce y Bi 2 Nb 2 o 9 , (x=y=0.005) weighed the ingredients, took absolute ethanol as the dispersion medium, put it in a nylon ball mill jar, and used a planetary ball mill to mill for 4 hours at a speed of 360rmp to obtain a mixed powder;

[0036] (2) Bake the mixed powder on a hot table for 12 hours, and after sieving, continuously raise the temperature to 900° C. in a box furnace and keep it warm for 2 hours to obtain bismuth-calcium niobate-based ceramic powder;

[0037] (3) Carry out secondary ball milling under the ball milling condition identical with step (1) with the synthetic bismuth calcium niobate base ceramic powder;

[0038] (4) Dry the powder after secondary ball milling, add 5wt% PVA to granulate,...

Embodiment 2

[0043] The preparation method of the rubidium and cerium co-doped bismuth calcium niobate-based high-temperature piezoelectric ceramics in this embodiment comprises the following steps:

[0044] (1) The raw material is according to the general formula Ca 1-x-y Rb x Ce y Bi 2 Nb 2 o 9 , (x=y=0.01) weigh the ingredients, use absolute ethanol as the dispersion medium, put it in a nylon ball mill jar, and use a planetary ball mill to mill for 4 hours at a speed of 360rmp to obtain a mixed powder;

[0045] (2) Bake the mixed powder on a hot table for 12 hours, and after sieving, continuously raise the temperature to 950° C. in a box furnace, and keep it warm for 2 hours to obtain bismuth calcium niobate-based ceramic powder;

[0046] (3) Carry out secondary ball milling under the ball milling condition identical with step (1) with the synthetic bismuth calcium niobate base ceramic powder;

[0047] (4) Dry the powder after secondary ball milling and add 5wt% PVA to granulate, ...

Embodiment 3

[0052] The preparation method of the rubidium and cerium co-doped bismuth calcium niobate-based high-temperature piezoelectric ceramics in this embodiment comprises the following steps:

[0053] (1) The raw material is according to the general formula Ca 1-x-y Rb x Ce y Bi 2 Nb 2 o 9 , (x=y=0.02) was weighed and batched, with absolute ethanol as the dispersion medium, placed in a nylon ball mill jar, and ball milled with a planetary ball mill at a speed of 360rmp for 4h to obtain a mixed powder;

[0054] (2) Bake the mixed powder on a hot table for 12 hours, and after sieving, continuously raise the temperature to 950° C. in a box furnace, and keep it warm for 2 hours to obtain bismuth calcium niobate-based ceramic powder;

[0055] (3) Carry out secondary ball milling under the ball milling condition identical with step (1) with the synthetic bismuth calcium niobate base ceramic powder;

[0056] (4) Dry the powder after secondary ball milling and add 5wt% PVA to granulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com