Modified asphalt coating, mineral granule surface modified asphalt waterproofing sheet material, preparation methods of coating and sheet material and mineral granule heating spreading device

A technology for modifying asphalt and mineral granules, applied in asphalt coatings, devices for coating liquid on surfaces, chemical instruments and methods, etc., can solve the problem of poor adhesion of mineral granules that affect the service life and waterproof performance of waterproof membranes , Mineral particles falling off and other problems, to achieve the effect of simple and exquisite device design, improve adhesion, and delay performance attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The second aspect of the present invention provides the preparation method of above-mentioned modified asphalt coating material, and this preparation method comprises:

[0033] (1) Grinding and mixing anhydrous asphalt with SBR to obtain a first mixture; then grinding and mixing said first mixture with SEBS to obtain a second mixture, and finally grinding and mixing said second mixture with a tackifying resin to obtain the third mixture;

[0034] (2) Mix the third mixture and the filler uniformly to obtain the coating material.

[0035] According to the present invention, preferably, in step (1), the dehydration method of the anhydrous asphalt is: dehydrating the asphalt above 160°C for 0.5-1.5h;

[0036] Grinding and mixing anhydrous asphalt and SBR at 180-200°C for 0.5-1h to obtain the first mixture; then grinding and mixing the first mixture and SEBS at 180-200°C for 1-1.5h to obtain the second mixture, and finally Grinding and mixing the second mixture with the ta...

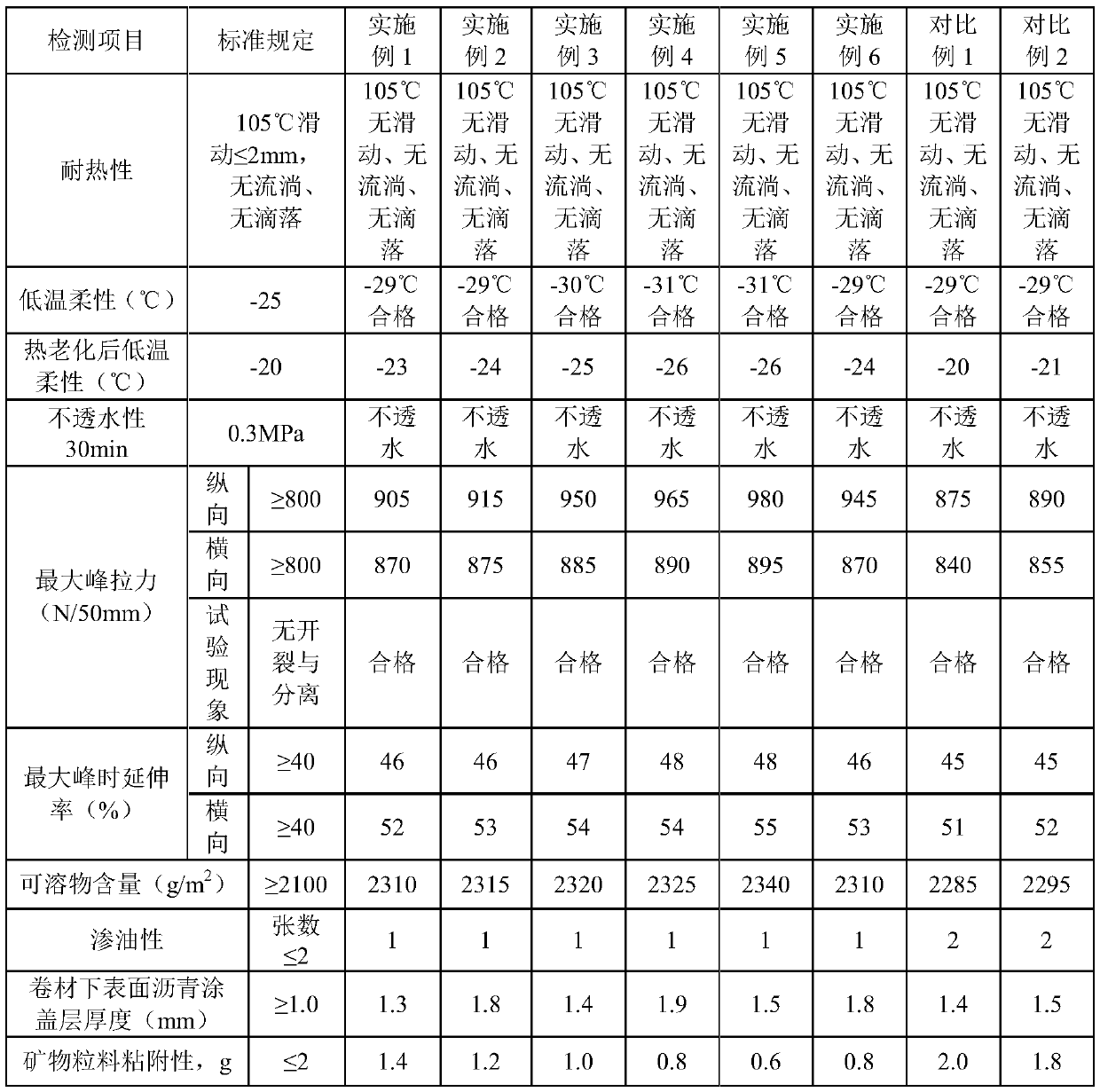

Embodiment 1

[0067] (1) Preparation of modified asphalt coating material: in the mixing tank, pour 58wt% asphalt, heat up to 160°C and dehydrate for 1 hour to obtain anhydrous asphalt; then, add 2wt% in the mixing tank SBR, start the colloid mill grinding, control the temperature at 190°C for 1 hour, then add 14wt% SEBS, continue to grind and stir at 190°C for 1 hour, then add 3wt% tackifying resin, continue to grind and stir at 190°C for 0.5 hours; finally, Add the mixed material and 23wt% filler after grinding and mixing with a colloid mill into the mixing tank, and continue to stir at 190°C for 1.5 hours to obtain the modified asphalt coating material.

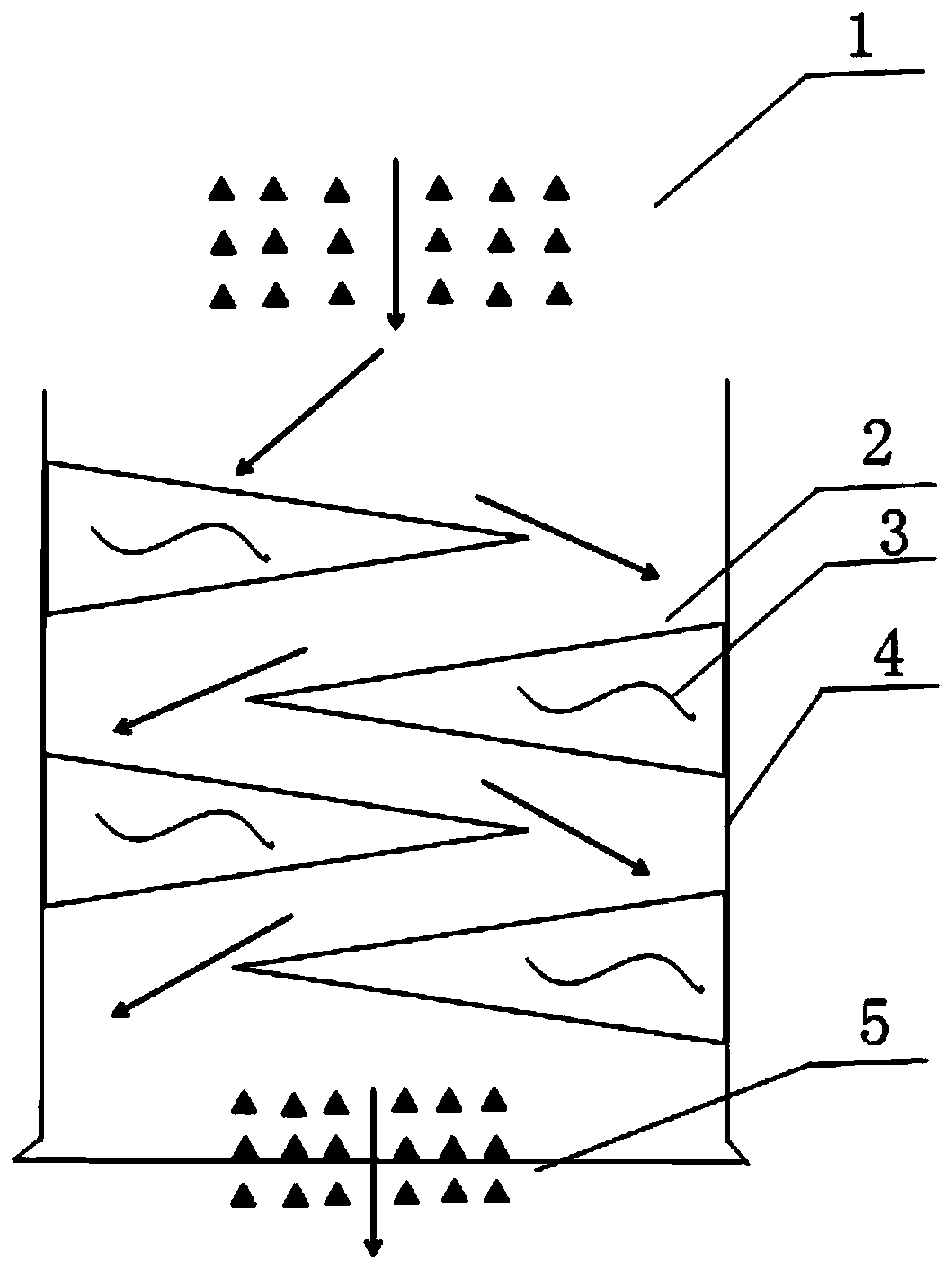

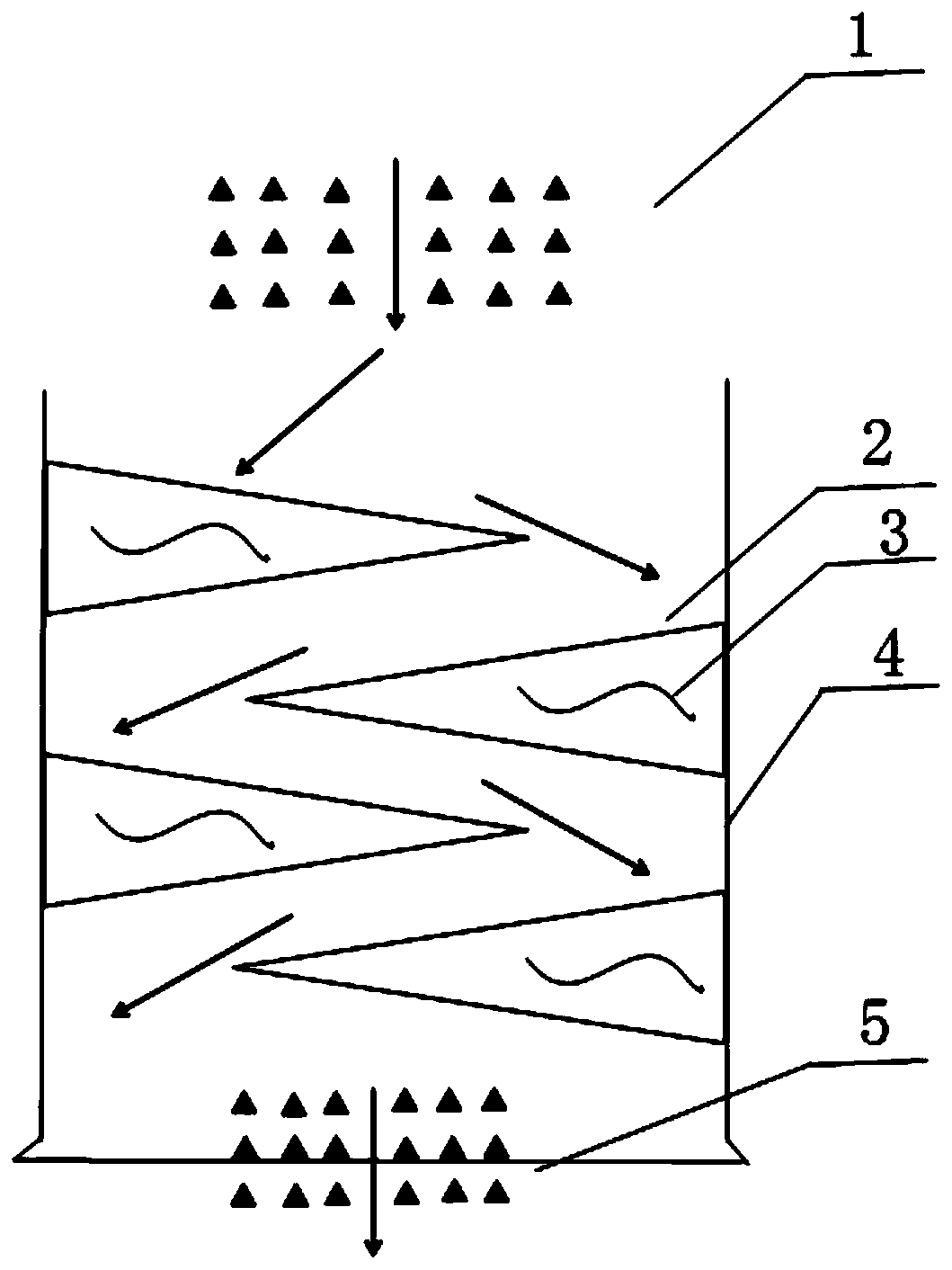

[0068] (2) Preparation of modified asphalt waterproofing membrane on the surface of mineral granules: long-fiber polyester non-woven fabric is used as the tire base, soaked with pre-impregnated oil, squeezed dry, and then covered with steps on both sides of the impregnated and squeezed tire base. The modified asphalt coating material pr...

Embodiment 2

[0070] (1) Preparation of modified asphalt coating material: In the mixing tank, pour 60wt% asphalt, heat up to 160°C and dehydrate for 1 hour to obtain anhydrous asphalt; then, add 3wt% in the mixing tank SBR, start the colloid mill grinding, control the temperature at 190°C for 0.5 hours, then add 13wt% SEBS, continue to grind and stir at 190°C for 1.5 hours, then add 3wt% tackifying resin, continue to grind and stir at 190°C for 1 hour; finally, Add the mixed material and 21wt% filler after colloid mill grinding and mixing into the mixing tank, and continue to stir at 190°C for 1.5 hours to obtain the modified asphalt coating material.

[0071] (2) Preparation of modified asphalt waterproofing membrane on the surface of mineral granules: long-fiber polyester non-woven fabric is used as the tire base, soaked with pre-impregnated oil, squeezed dry, and then covered with steps on both sides of the impregnated and squeezed tire base. The modified asphalt coating material prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com