A kind of based on cesium lead iodine photodetector and preparation method

A photodetector, cesium lead technology, applied in the field of photodetectors, can solve the problems of device performance failure, easy decomposition and phase change, etc., and achieve the effect of good device performance, simple preparation process and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

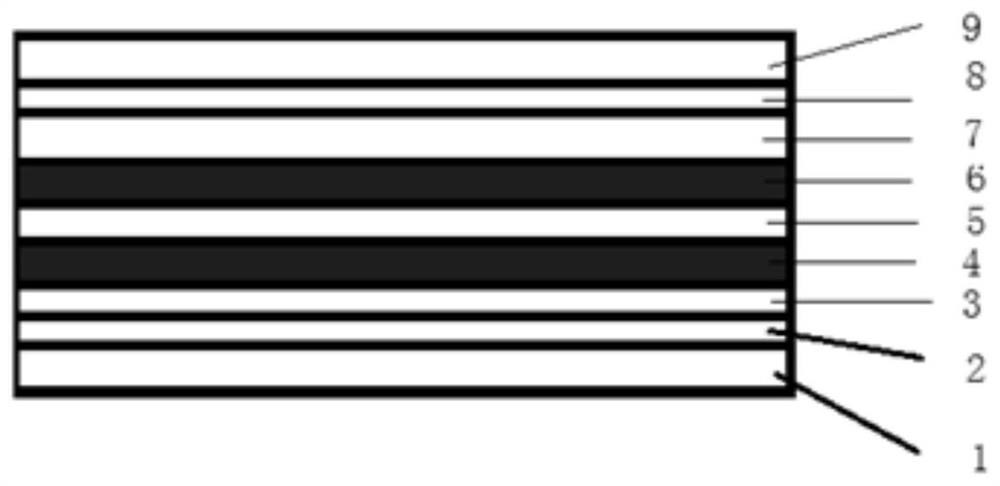

[0017] Embodiment one: on the substrate layer of silicon with oxide layer grown on the surface, adopt the chemical vapor deposition method to deposit lead iodide PbI with a thickness of 2 nanometers on the electrode layer surface successively 2 layer, further deposited on it with a thickness of 2 nanometers of cesium iodide CsI layer, and then deposited and grown with a thickness of 2 nanometers of lead iodide layer; Two layers of perovskite cesium lead iodide CsPbI with a thickness of 2 nm were obtained at the two interface layers 3 A photosensitive layer; then an electrode with a thickness of 20 nanometers is evaporated on the surface of the lead iodide; finally, a protective layer of polymethyl methacrylate PMMA device is spin-coated on the surface of the electrode layer, and the thickness of the protective layer is 20 nanometers.

Embodiment 2

[0018] Embodiment two: on the glass sheet substrate layer, adopt the chemical vapor deposition method, deposit the lead iodide PbI that thickness is 2 nanometers successively on the electrode layer surface 2 layer, further deposited on it with a thickness of 2 nanometers of cesium iodide CsI layer, and then deposited and grown with a thickness of 2 nanometers of lead iodide layer; Two layers of perovskite cesium lead iodide CsPbI with a thickness of 8 nm were obtained at the two interface layers 3 photosensitive layer; then evaporate an electrode with a thickness of 50 nanometers on the surface of lead iodide; finally spin-coat a polymethyl methacrylate PMMA device protection layer on the surface of the electrode layer, and the thickness of the protection layer is 50 nanometers.

Embodiment 3

[0019] Embodiment three: above the substrate layer of the silicon that surface grows oxide layer, adopt chemical vapor deposition method, deposit the lead iodide PbI that thickness is 5 nanometers successively on electrode layer surface 2 layer, further deposited on it with a thickness of 2 nanometers of cesium iodide CsI layer, and then deposited and grown with a thickness of 2 nanometers of lead iodide layer; Two layers of perovskite cesium lead iodide CsPbI with a thickness of 3 nm were obtained at the two interface layers 3 A photosensitive layer; then an electrode with a thickness of 40 nanometers is evaporated on the surface of the lead iodide; finally, a protective layer of polymethyl methacrylate PMMA device is spin-coated on the surface of the electrode layer, and the thickness of the protective layer is 40 nanometers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com