Method for recovering gold and copper from copper ore biological dump leaching tailings

A technology for biological stacks and gold recovery, applied in the direction of improving process efficiency, can solve the problems of not worth the loss, unfriendly environment, low gold adsorption rate, etc., and achieve good economic and social benefits, environmental friendliness, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

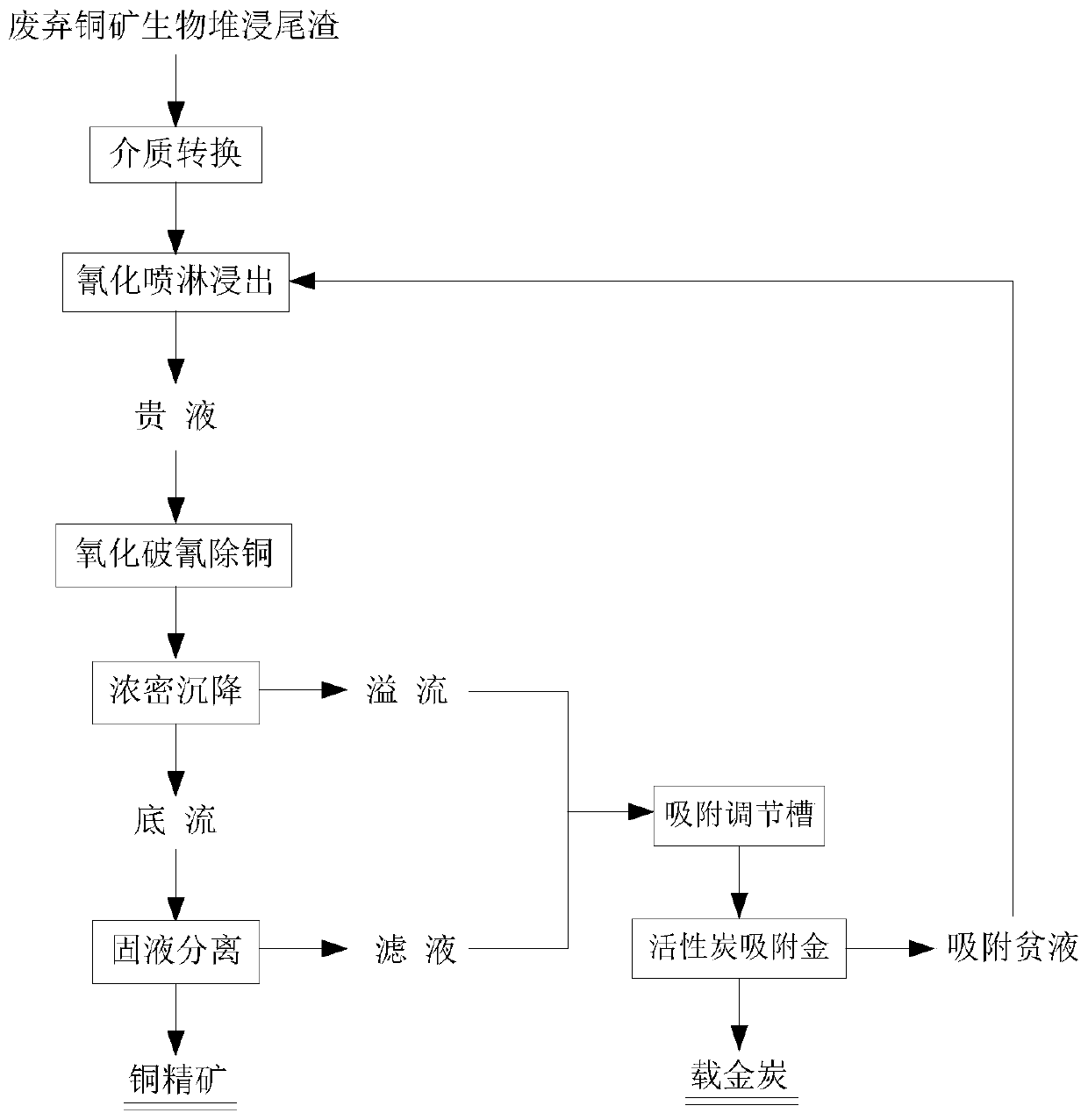

Image

Examples

Embodiment 1

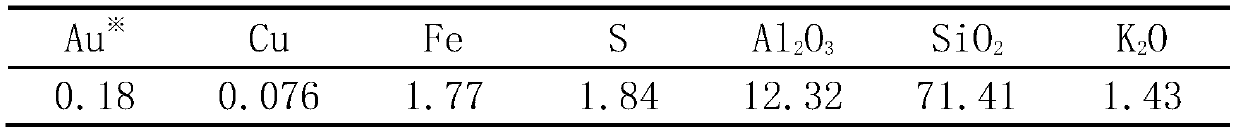

[0031] In the bioheap leaching tailings of an abandoned copper mine in Fujian, copper mainly exists in the form of copper blue. The main element analysis results of the bioheap leaching tailings of the abandoned copper mine are shown in Table 1.

[0032] Table 1 Multi-element analysis results of bioheap leaching tailings of an abandoned copper mine in Fujian (%)

[0033]

[0034] Note:" ※ "The unit is g / t, the same below.

[0035] The method for recovering gold and copper from the leaching tailings of the abandoned copper ore biological heap comprises the following steps in sequence.

[0036] The first step of medium conversion: the waste copper ore bioheap leaching tailings are not unloaded, and the first stage of medium conversion uses mine alkaline wastewater to continuously spray the waste copper ore bioheap leaching tailings for 5 days, and the spray intensity is 50L / m 2 .h; the second stage of medium conversion is to spread lime on the heap surface first, and then u...

Embodiment 2

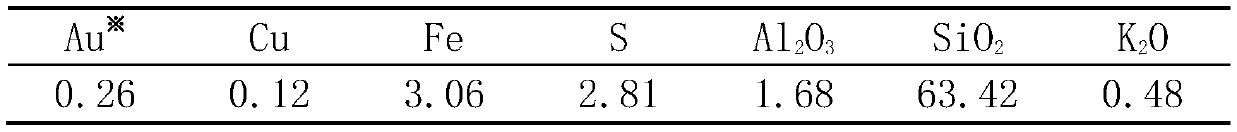

[0042] In the bioheap leaching tailings of an abandoned copper mine in Heilongjiang, copper mainly exists in the form of copper blue and arsenic copper ore. The main element analysis results of the bioheap leaching tailings of the abandoned copper mine are shown in Table 2.

[0043] Table 2 Multi-element analysis results of bioheap leaching tailings of an abandoned copper mine in Heilongjiang (%)

[0044]

[0045] The method for recovering gold and copper from the leaching tailings of the abandoned copper ore biological heap comprises the following steps in sequence.

[0046] The first step of medium conversion: the waste copper ore bioheap leaching tailings are not unloaded, and the first stage of medium conversion uses mine alkaline wastewater to continuously spray the waste copper ore bioheap leaching tailings for 7 days, and the spray intensity is 30L / m 2 .h; the second stage of medium conversion is to spread lime on the heap surface first, and then use mine alkaline wa...

Embodiment 3

[0052] In the bioheap leaching tailings of an abandoned copper mine in Yunnan, copper mainly exists in the form of copper blue. The main element analysis results of the bioheap leaching tailings of the abandoned copper mine are shown in Table 3.

[0053] Table 3 Multi-element analysis results of bioheap leaching tailings of an abandoned copper mine in Yunnan (%)

[0054]

[0055] The method for recovering gold and copper from the leaching tailings of the abandoned copper ore biological heap comprises the following steps in sequence.

[0056] The first step of medium conversion: the waste copper ore bioheap leaching tailings are not unloaded, and the first stage of medium conversion uses mine alkaline wastewater to continuously spray the waste copper ore bioheap leaching tailings for 6 days, and the spray intensity is 40L / m 2 .h; the second stage of medium conversion is to spread lime on the heap surface first, and then use the mine alkaline wastewater to spray the waste cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com