Preparation method of sodium hexafluoroaluminate

A technology for sodium hexafluoroaluminate and aluminum ash, which is applied in the field of preparation of sodium hexafluoroaluminate, can solve the problems of high energy consumption, waste of available resources, environmental hazards, etc. , Easy to operate, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

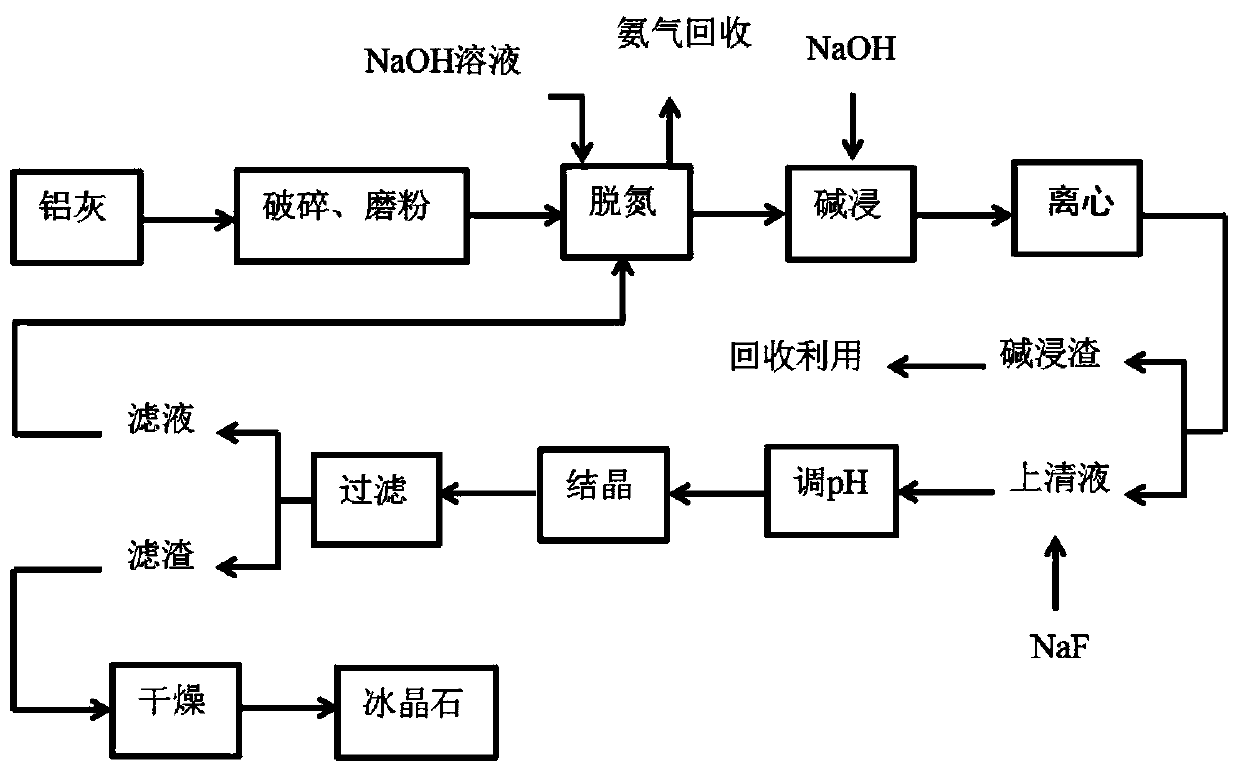

[0028] The invention provides a sodium hexafluoroaluminate (cryolite, Na 3 AlF 6 ) preparation method, comprising the following steps:

[0029] The denitrified aluminum ash is mixed with sodium hydroxide to carry out alkali leaching reaction, and then separated to obtain a supernatant solution;

[0030] The supernatant solution was crystallized to obtain sodium hexafluoroaluminate.

[0031] In the present invention, unless otherwise specified, the raw materials used are conventional commercially available products in this field.

[0032] In the invention, the denitrified aluminum ash is mixed with sodium hydroxide to carry out alkaline leaching reaction, and then separated to obtain a supernatant solution.

[0033] In the present invention, denitrification is preferably performed after the aluminum ash is crushed to obtain a denitrified solution, and the denitrified solution includes the denitrified aluminum ash. In the embodiment of the present invention, the denitrified ...

Embodiment 1

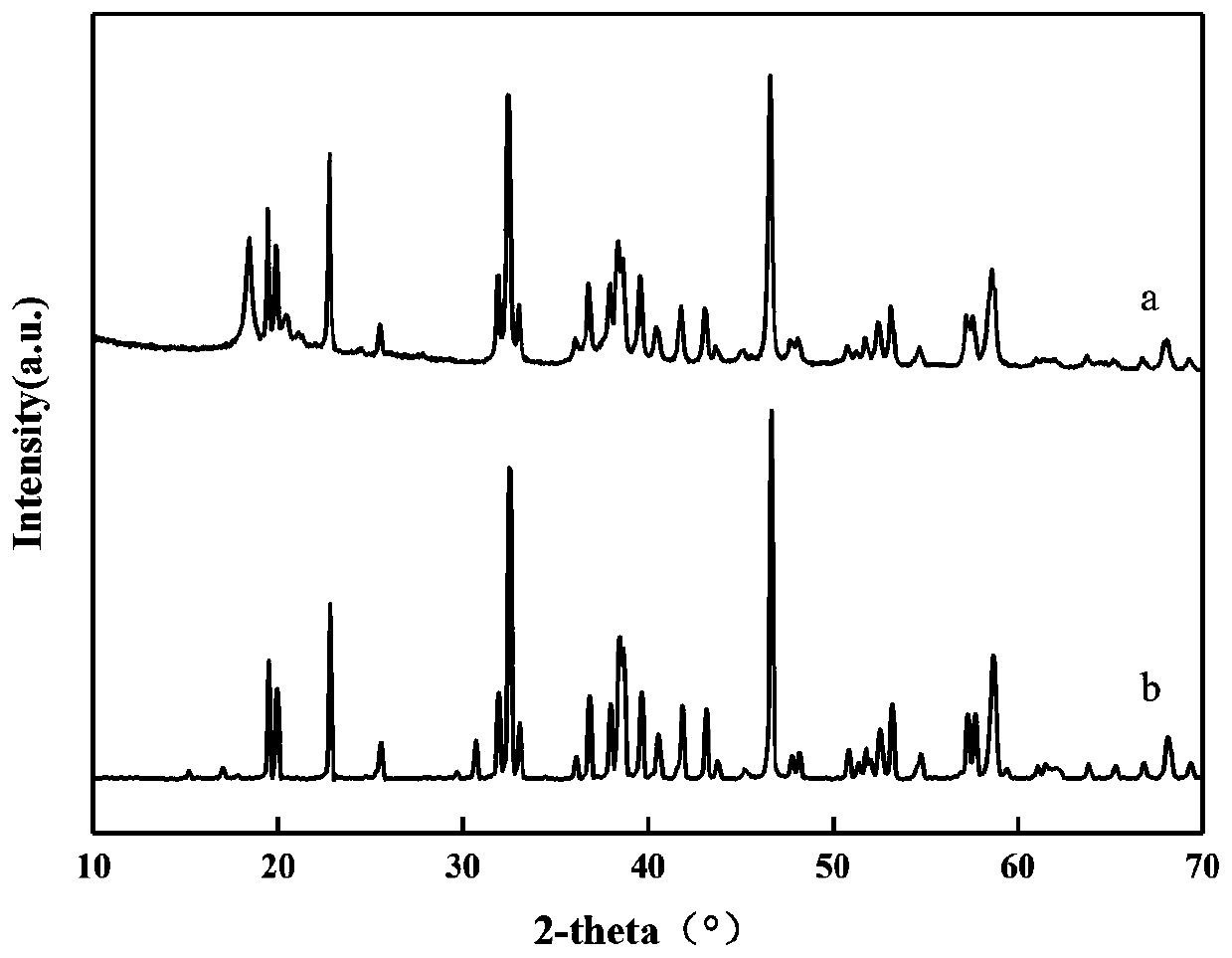

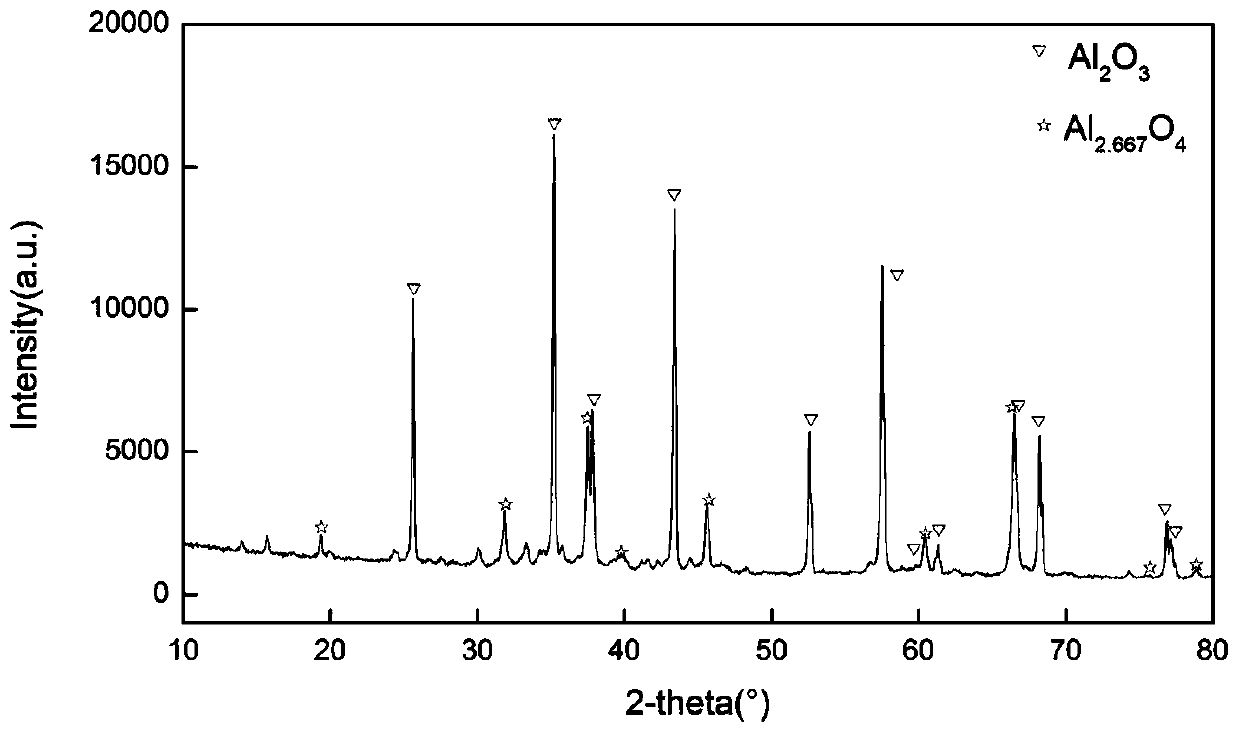

[0045] Effect of different crystallization pH values on the preparation of sodium hexafluoroaluminate

[0046] Grind 10g of aluminum ash into a powder with a particle size of 300 mesh, add 100mL of sodium hydroxide solution with a mass concentration of 10%, and denitrify at a temperature of 100-110°C and a stirring speed of 150r / min, then recover Add 6g of sodium hydroxide to the ammonia gas obtained by denitrification, and carry out alkali leaching reaction at a temperature of 75°C and a stirring speed of 150r / min. After the alkali leaching reaction, centrifuge to obtain a supernatant solution and filter residue. After adding 3g of sodium fluoride to the supernatant solution, use NaOH with a molar concentration of 5mol / L to adjust the pH value of the supernatant solution to 6.07, 8.09, 10.06 and 13.18 respectively, and crystallize at 25°C. After filtering, Dry at 65°C to obtain sodium hexafluoroaluminate, which can be obtained through analysis, and the purity of the prepare...

Embodiment 2

[0052] Effect of Different Crystallization Temperatures on the Preparation of Sodium Hexafluoroaluminate

[0053] Grind 10g of aluminum ash into a powder with a particle size of 300 mesh, add 100mL of sodium hydroxide solution with a mass concentration of 10%, and denitrify at a temperature of 100-110°C and a stirring speed of 150r / min, then recover The ammonia gas obtained by denitrification is added with a sodium hydroxide solution with a mass concentration of 8%, and the alkali leaching reaction is carried out at a temperature of 75° C. and a stirring speed of 150 r / min. After the alkali leaching reaction, centrifugation is carried out to obtain the above After adding 3g sodium fluoride to the supernatant solution and the filter residue, use NaOH with a molar concentration of 5mol / L, adjust the pH value of the supernatant solution to 10, and set the temperature at 2°C, 25°C, 50°C and 75°C respectively. Crystallize under the condition of ℃, filter and dry at 65℃ to obtain so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com