Thermal insulation method of closed thermal battery

A thermal battery, closed technology, applied in the use/maintenance of primary batteries, battery pack components, primary batteries to battery grouping, etc., to achieve obvious effects, solve safety problems, and simple and easy measures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A thermal isolation method for a closed thermal battery, the thermal isolation treatment method is interrupted or bridged; when the area requiring thermal isolation is a parallel monomer room, the interrupted thermal isolation is used, and the processing method is : In the area with the highest operating temperature of the battery, a pyrotechnic system or thermal insulation material is added between two monomers connected in parallel in the battery stack; the interrupted thermal insulation is thermal insulation at one or more places in the battery stack ; The thickness of the pyrotechnic system is 1-30mm; The thickness of the thermal insulation material is 1-30mm;

[0035] When the area requiring thermal isolation is between cells connected in series, a bridge type is used for thermal isolation. The treatment method is: in the highest temperature area where the thermal battery works, a thermal isolation material is added between the two cells connected in series in the b...

Embodiment 2

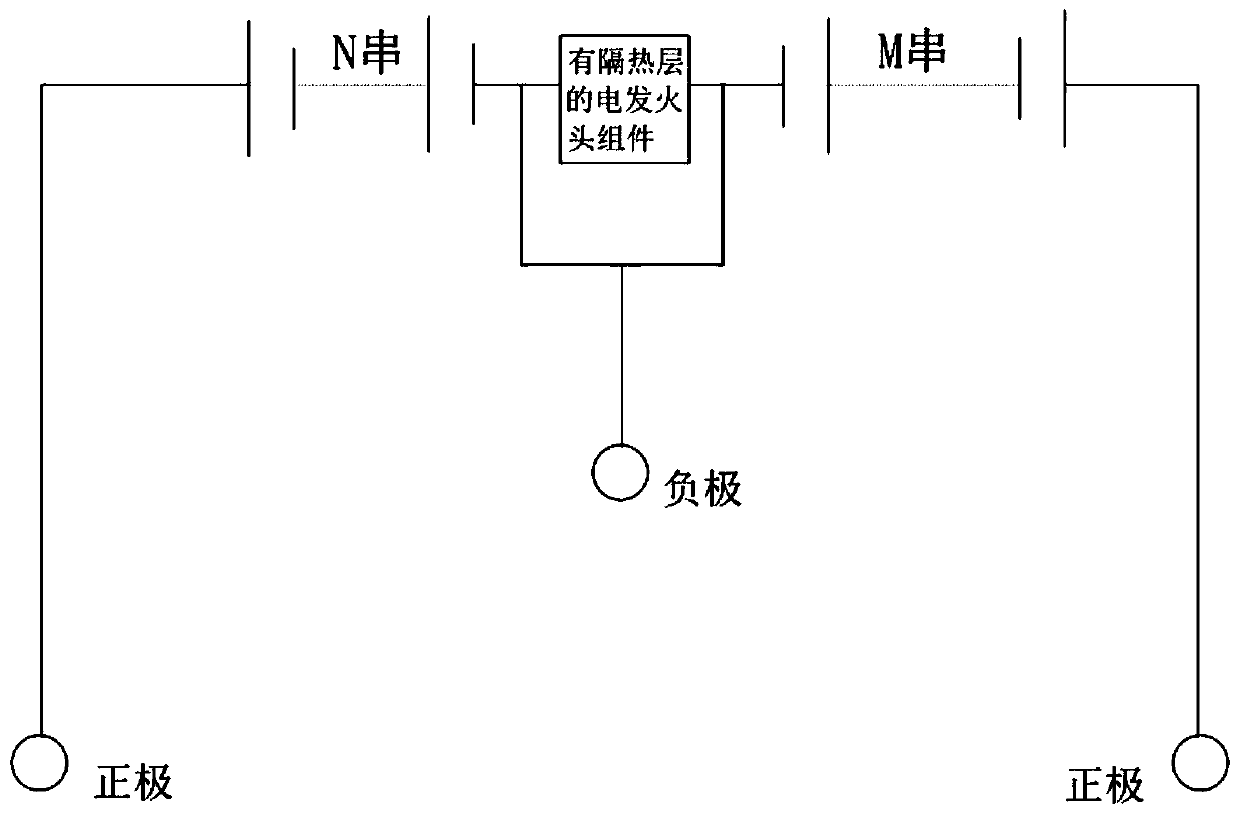

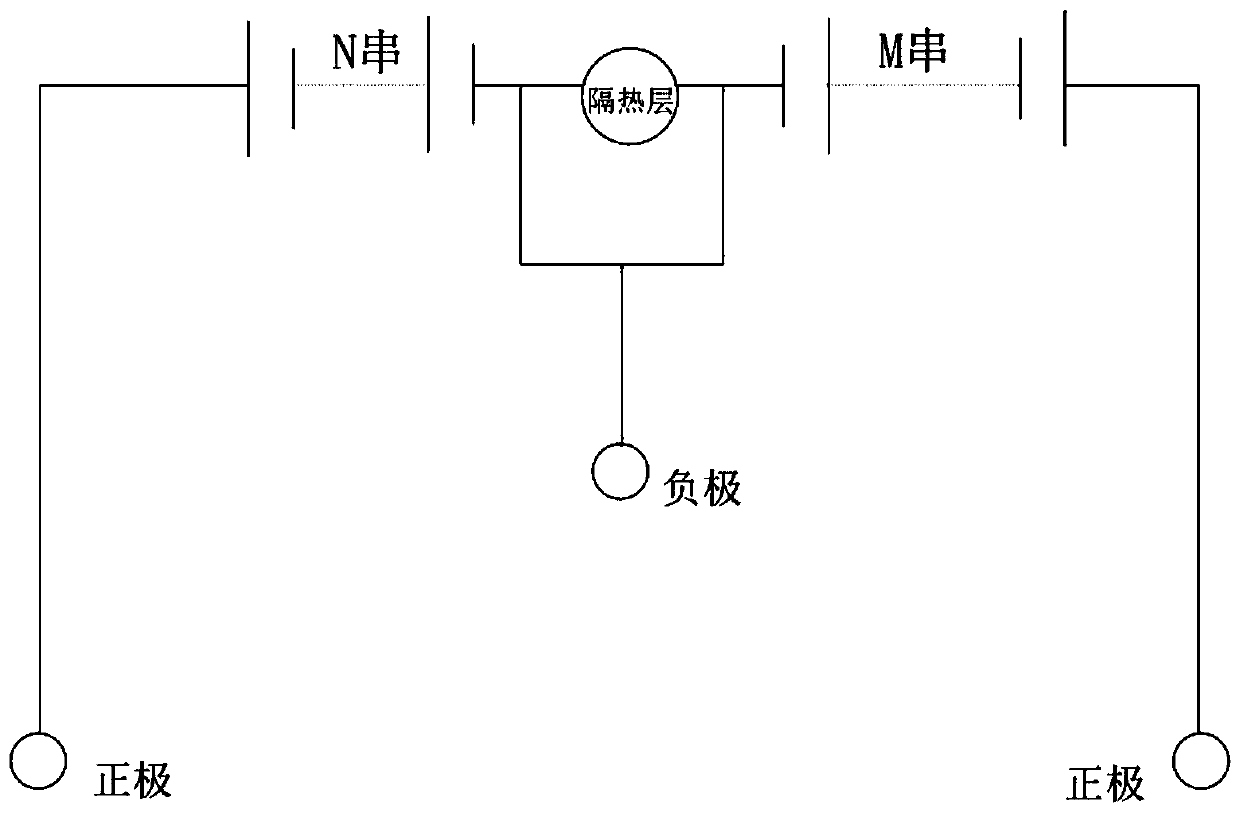

[0038] A thermal isolation method for a closed thermal battery. The area that needs thermal isolation is between parallel monomers, and the thermal isolation is performed in an interrupted manner. A pyrotechnic system or thermal insulation material is added between each cell; the interrupted thermal insulation is thermal insulation at one or more places in the battery stack; the thickness of the pyrotechnic system is 1-30 mm; the thermal insulation The thickness of the material is 1-30mm; the thermal insulation material is flexible thermal insulation material, mica, asbestos paper, Min-K material, ceramic membrane, hollow skeleton aluminum, hollow skeleton copper, airgel gasket, glass fiber, silicon One or more of alumina fibers, high silica fibers or thermal insulation blankets. The schematic diagram of the working circuit of this embodiment is as figure 2 or 2, the schematic diagram of the structure of the thermal battery after thermal isolation is as follows Figure 6 sh...

Embodiment 3

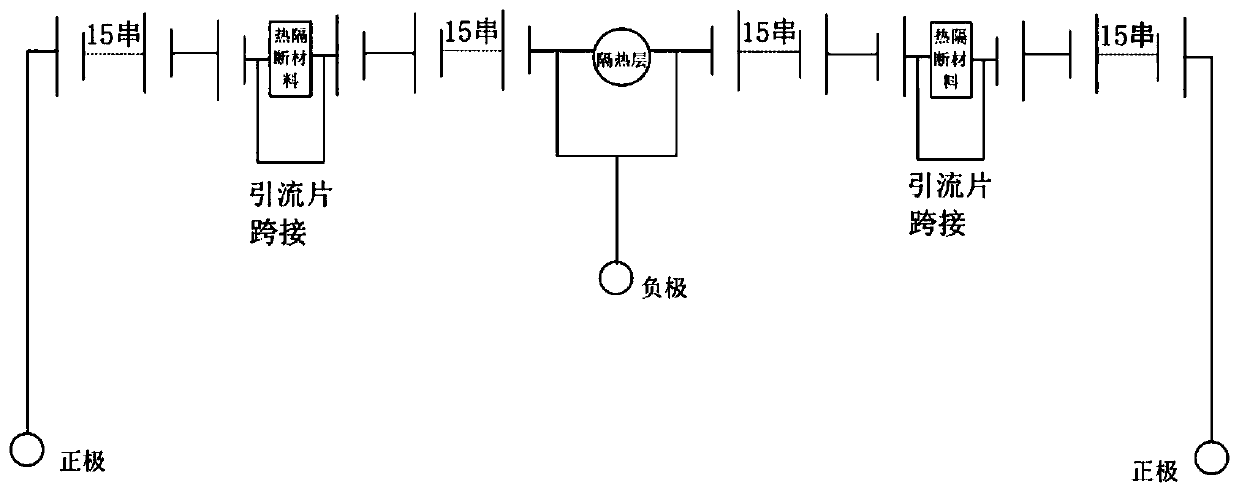

[0040]A thermal isolation method for a closed thermal battery. The area that needs thermal isolation is between the monomers connected in series, and a bridge type is used for thermal isolation. A thermal insulation material is added between the individual cells, and the current flow between the isolated cells is realized by adding a drain piece at the partition to bridge; Partition; the drainage sheet is one or more of silver, copper, iron, nickel metal products; the thickness of the thermal insulation material is 1-30mm; the thermal insulation material is flexible thermal insulation material, mica, One or more of asbestos paper, Min-K material, ceramic membrane, hollow skeleton aluminum, hollow skeleton copper, airgel gasket, glass fiber, aluminum silicate fiber, high silica fiber or thermal insulation blanket. The schematic diagram of the working circuit after thermal isolation of this embodiment is as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com