Secondary battery

A secondary battery and current collector technology, applied in the direction of secondary batteries, battery electrodes, battery components, etc., can solve the problem of being unable to cope with large-capacity batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

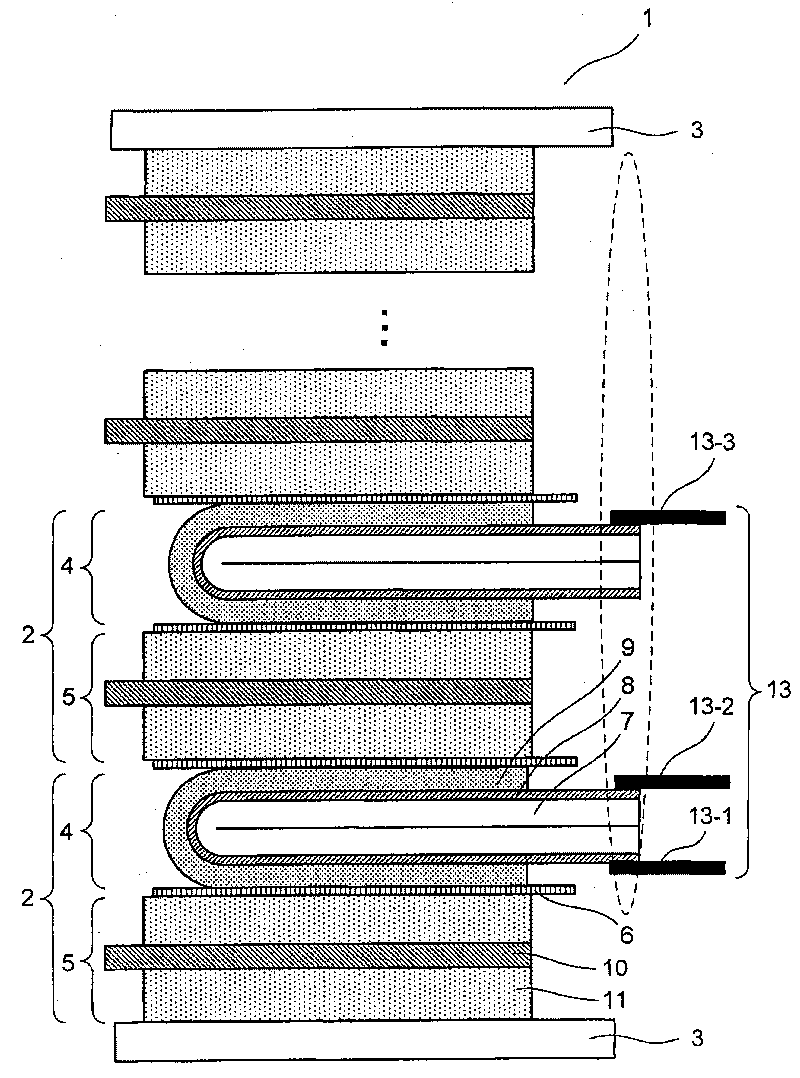

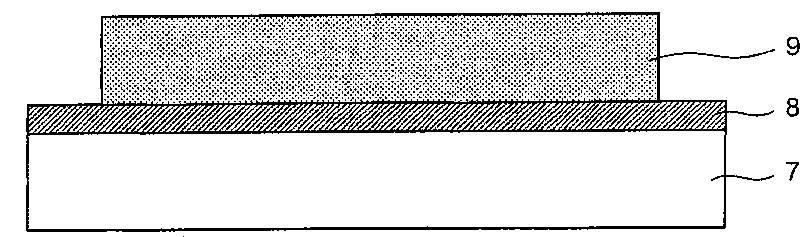

[0071] Hereinafter, Embodiment 1 of the secondary battery of the present invention will be described with reference to FIG. 2 . In this example, first, manufacture a Figure 2A The electrode part of the structure shown. In this embodiment, an electrode having a resin film as a core material serving as a positive electrode and an electrode having a negative electrode active material applied on a metal foil serving as a negative electrode will be described.

[0072] As the resin film 7 , a biaxially stretched polypropylene film (Toray Industries, Ltd.: film YK57) having a thickness of 15 μm, a width of 80 mm, and a length of 350 mm was used. On the resin film 7, aluminum (1.5 [mu]m thick) for the metal layer 8 for the positive electrode current collector was formed by vacuum vapor deposition. On top of it, apply LiFePO with olivine structure 4 The positive electrode active material layer 9 (active material: acetylene black: PVDF = 90:5:5 (weight ratio)) as a positive electrod...

Embodiment 2

[0085] Compared with the secondary battery in Example 1, the secondary battery in Example 2 of the present invention is different in that LiMn of olivine structure is used 2 o 4 For the positive electrode active material. In other respects, the structure is similar to Embodiment 1.

Embodiment 3

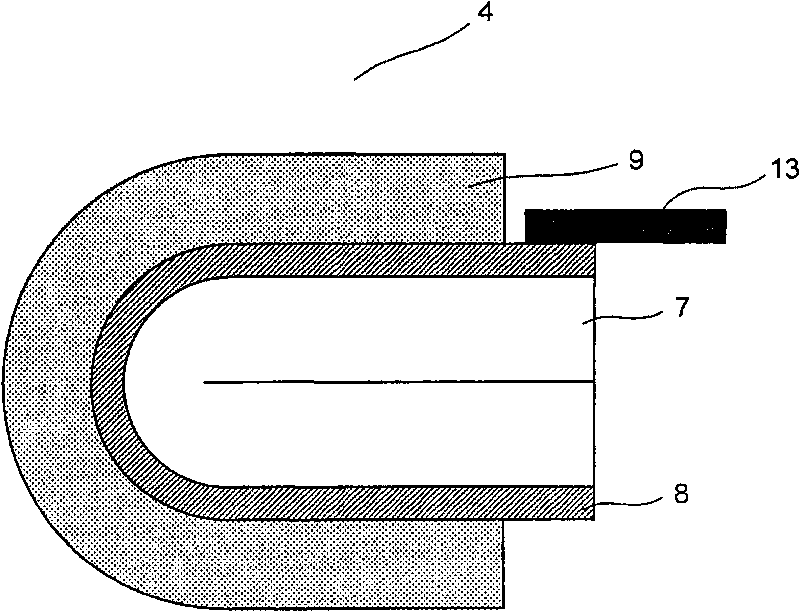

[0091] Next, refer to image 3 with 4 Embodiment 3 of the secondary battery of the present invention is described. The content similar to that in Embodiment 1 will not be described. In Example 1, the current collectors having resin as the core material were stacked sequentially, while in this Example 3, the current collectors (positive electrodes in Example 3) having resin as the core material were folded into a screen shape.

[0092] First, a strip-shaped positive electrode 7 is prepared. Here, the shape required to form one secondary battery is 80 mm wide and 3300 mm long. Since it is so long, it remains coiled during operation.

[0093] As the negative electrode, one having the same specifications as in Example 1 was used.

[0094] Regarding the above-mentioned members, a secondary battery was obtained in the following procedure.

[0095] (a) The separator 6 is stacked on the negative electrode 5 .

[0096] (b) The positive electrode 4 is formed, and the resin film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com