A method of preparing lithium battery anode material by using calcined organic silicide

A lithium battery anode, organic silicide technology, applied in battery electrodes, circuits, electrical components, etc., to achieve the effects of low raw material prices, good application prospects, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

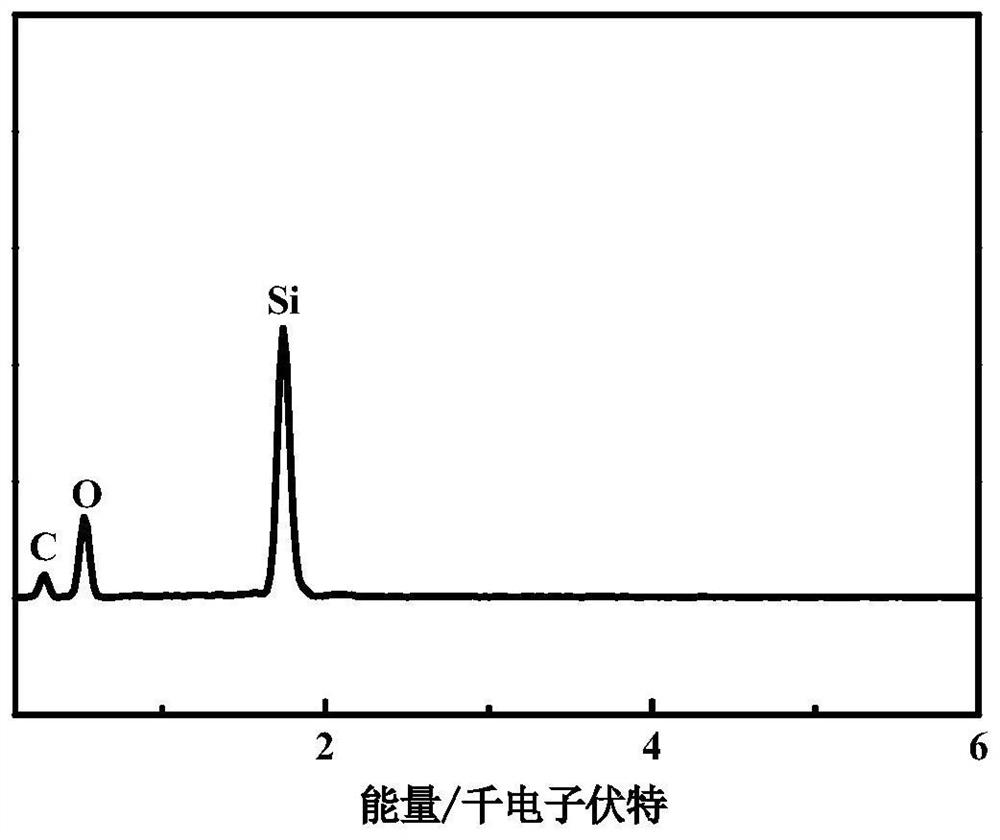

[0018] Select trimethylsilanol as the raw material, measure 30 mL of the material, place it in a porcelain crucible, and put it into a muffle furnace for calcination at 450° C. for 2 h. Weigh the calcined upper white substance and grind it for 20 minutes to obtain the product, which is called active substance.

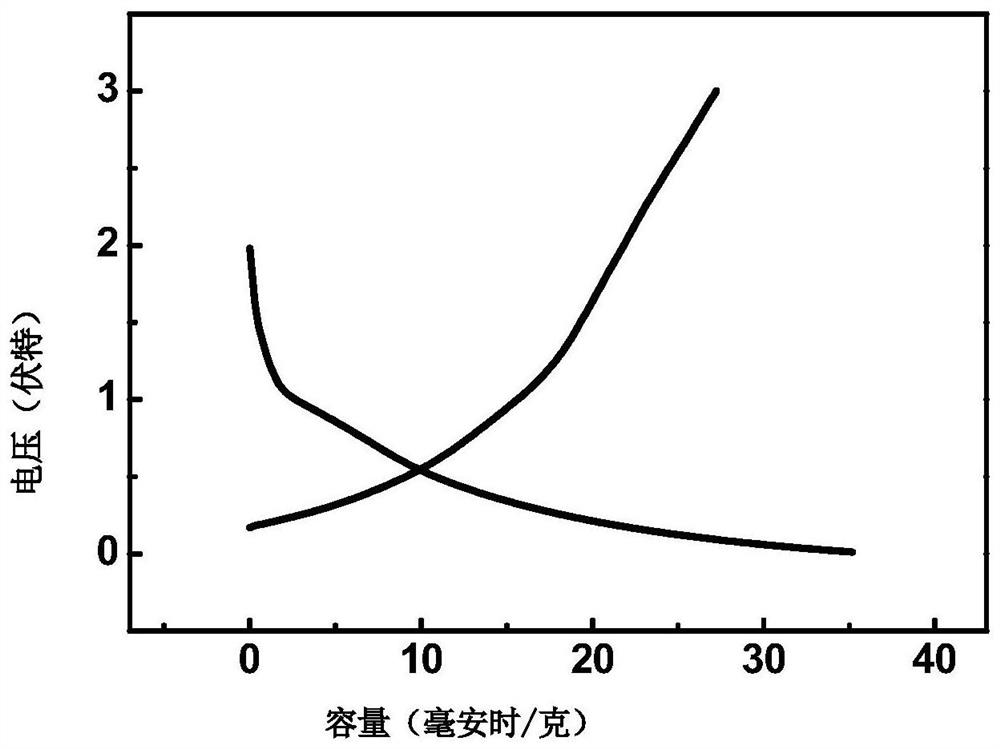

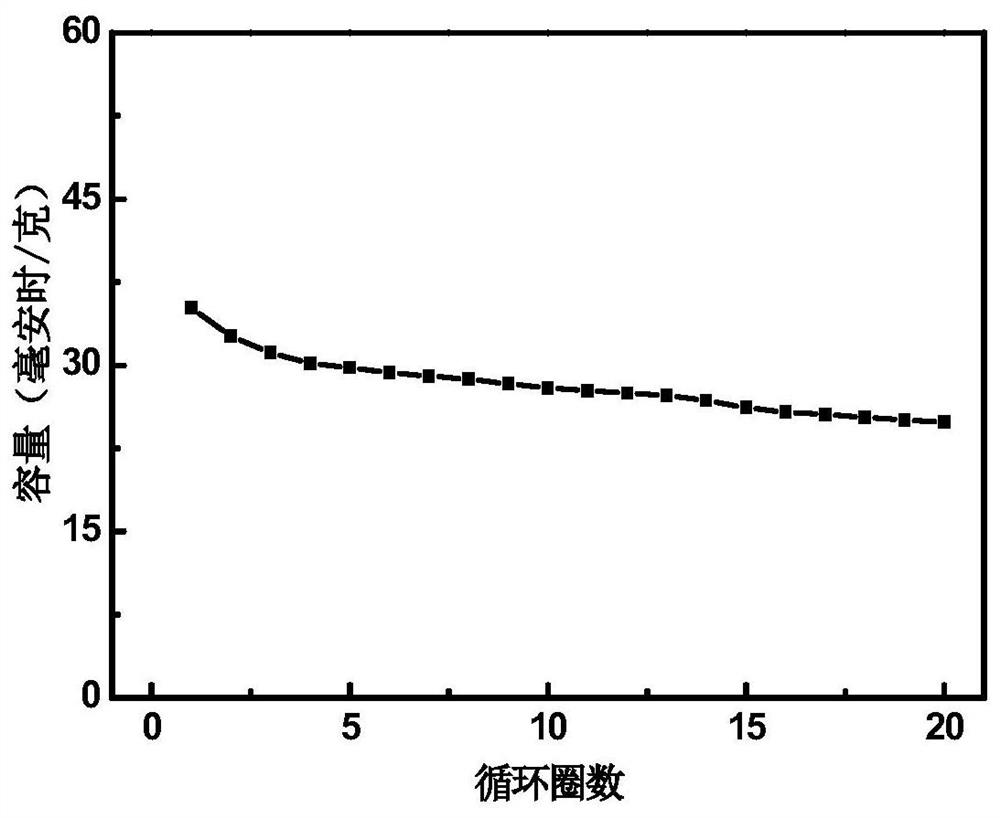

[0019] After weighing the active substance, acetylene black and polyvinylidene fluoride according to the mass ratio of 8:1:1, put them in an agate mortar, stir and grind them evenly, then add a few drops of N-methylpyrrolidone, and continue to fully Stir to form a homogeneous slurry. Then use a glass sheet to evenly press and spread the slurry on the copper foil, and then put it into a vacuum drying oven to evacuate and dry at 120° C. for 12 hours. After cooling down, it is used as the positive electrode of the battery. Then take the lithium sheet as the negative electrode, use polypropylene 2400 as the separator, and use 1mol / L LiPF in organic solvent 6 As the elec...

Embodiment 2

[0025] Hexamethyldisiloxane was selected as the raw material, 30 mL of the raw material was measured and placed in a porcelain crucible, and put into a muffle furnace for calcination at 600° C. for 2.5 h. The calcined upper white substance was weighed and ground for 20 minutes, and the obtained substance was the active substance. The test method of the assembled battery is the same as that of Example 1. It is confirmed that the prepared material has a certain capacity and has good cycle stability.

Embodiment 3

[0027] Choose simethicone oil as the raw material, measure 30mL of the raw material, place it in a porcelain crucible, put it into a muffle furnace and calcinate at 800°C for 1h. The calcined upper white substance was weighed and ground for 25 minutes, and the obtained substance was the active substance. The test method of the assembled battery is the same as that of Example 1. It is confirmed that the prepared material has a certain capacity and has good cycle stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com