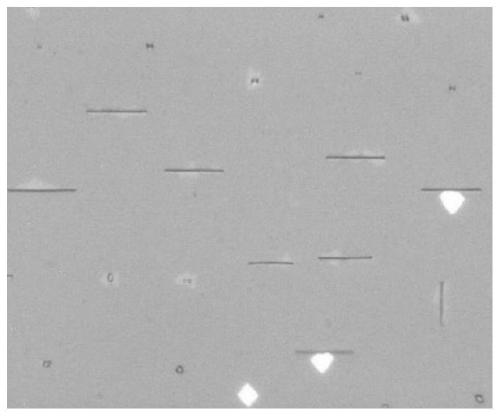

Molybdenum disulfide@molybdenum disulfide core-shell nano rod growing along <010> crystal orientation and preparation method thereof

A molybdenum dioxide and molybdenum disulfide technology is applied in the field of nanomaterials to achieve the effects of uniform growth distribution, good crystallinity and high orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

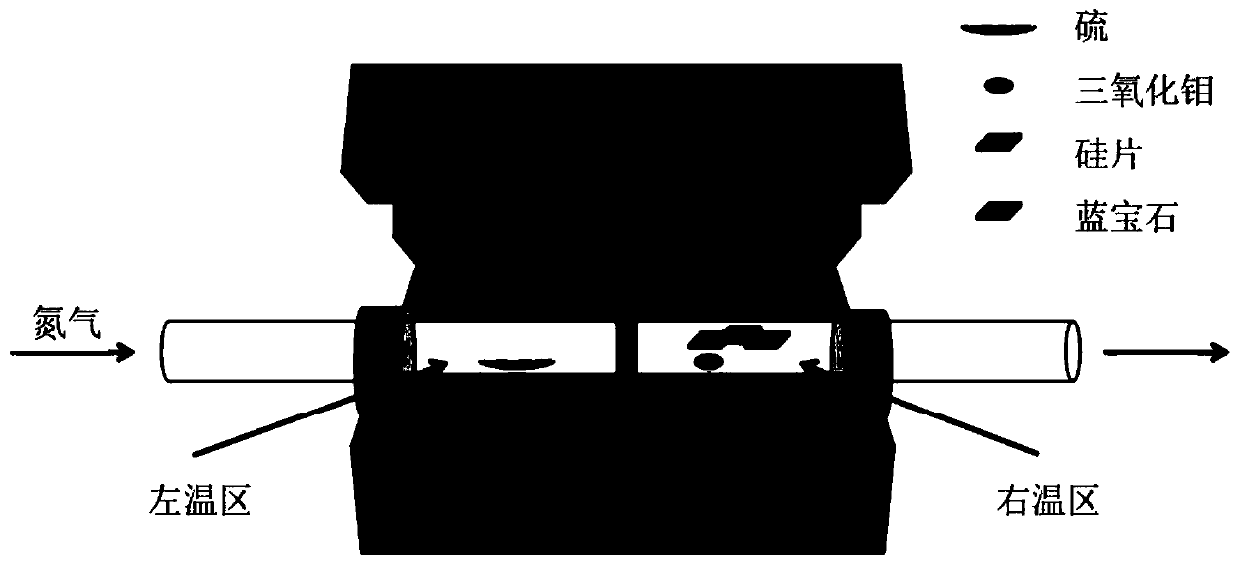

[0033] The invention provides a method for preparing molybdenum dioxide@molybdenum disulfide core-shell nanorods grown along the crystal direction, comprising the following steps:

[0034] Using the m-plane of sapphire as the substrate, sulfur block and molybdenum trioxide powder as the reaction raw materials, carry out atmospheric pressure chemical vapor deposition to obtain molybdenum dioxide@molybdenum disulfide core-shell nanorods grown along the crystal direction; the sulfur The mass ratio of block to molybdenum trioxide powder is 25-35:1.

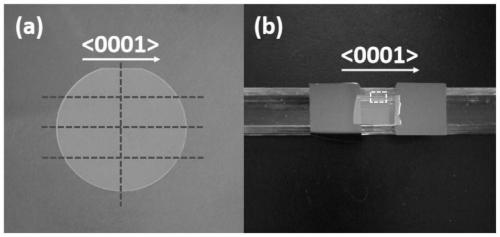

[0035] In the present invention, the substrate is preferably an elongated substrate. In the present invention, the length of the elongated substrate is preferably 2 cm to 3 cm, more preferably 2.5 cm; the width is preferably 1 to 2 cm, more preferably 1.5 cm.

[0036] In the present invention, the left edge of the substrate is preferably placed directly above the molybdenum trioxide powder.

[0037]In the present invention, the su...

Embodiment 1

[0057] 1) First cut the m-plane sapphire into strip-shaped substrates along its crystal direction with a glass knife. The substrates were cleaned in an ultrasonic oscillator with deionized water, acetone, isopropanol and hydrogen peroxide, and each process took 15 minutes. Blow dry the substrate with a nitrogen gun for later use.

[0058] 2) Put the weighed 450mgS block into the quartz ark, 15mgMoO 3 The powder is put into the quartz ark, and the left edge of the substrate is placed on the MoO 3 Powder is right on top.

[0059] 3) will be loaded with MoO 3 The quartz ark of powder and substrate is placed in the right temperature zone of the CVD tube furnace, and the sapphire substrate is located in the center of the right temperature zone, and the quartz ark equipped with the S block is placed in the center of the left temperature zone, and then the tube furnace is sealed. N 2 As carrier gas and shielding gas.

[0060] 4) Set the growth program, the temperature in the fi...

Embodiment 2

[0079] 1) First cut the m-plane sapphire into strip-shaped substrates along its crystal direction with a glass knife. The substrates were cleaned in an ultrasonic oscillator with deionized water, acetone, isopropanol and hydrogen peroxide, and each process took 15 minutes. Blow dry the substrate with a nitrogen gun for later use.

[0080] 2) Put the weighed 350mgS block into the quartz ark, 10mgMoO 3 The powder is put into the quartz ark, and the left edge of the substrate is placed on the MoO 3 Powder is right on top.

[0081] 3) will be loaded with MoO 3 The quartz ark of powder and substrate is placed in the right temperature zone of the CVD tube furnace, and the sapphire substrate is located in the center of the right temperature zone, and the quartz ark equipped with the S block is placed in the center of the left temperature zone, and then the tube furnace is sealed. N 2 As carrier gas and shielding gas.

[0082] 4) Set the growth program, the temperature in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com