Preparation method for battery backplanes

A technology of battery backplane and rolling method, which is applied in the field of solar energy, can solve the problems of poor flame retardant effect, poor barrier effect of battery backplane, and low service life of photovoltaic backplane, so as to improve stability and service life, heat conduction and heat dissipation effect The effect of good, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

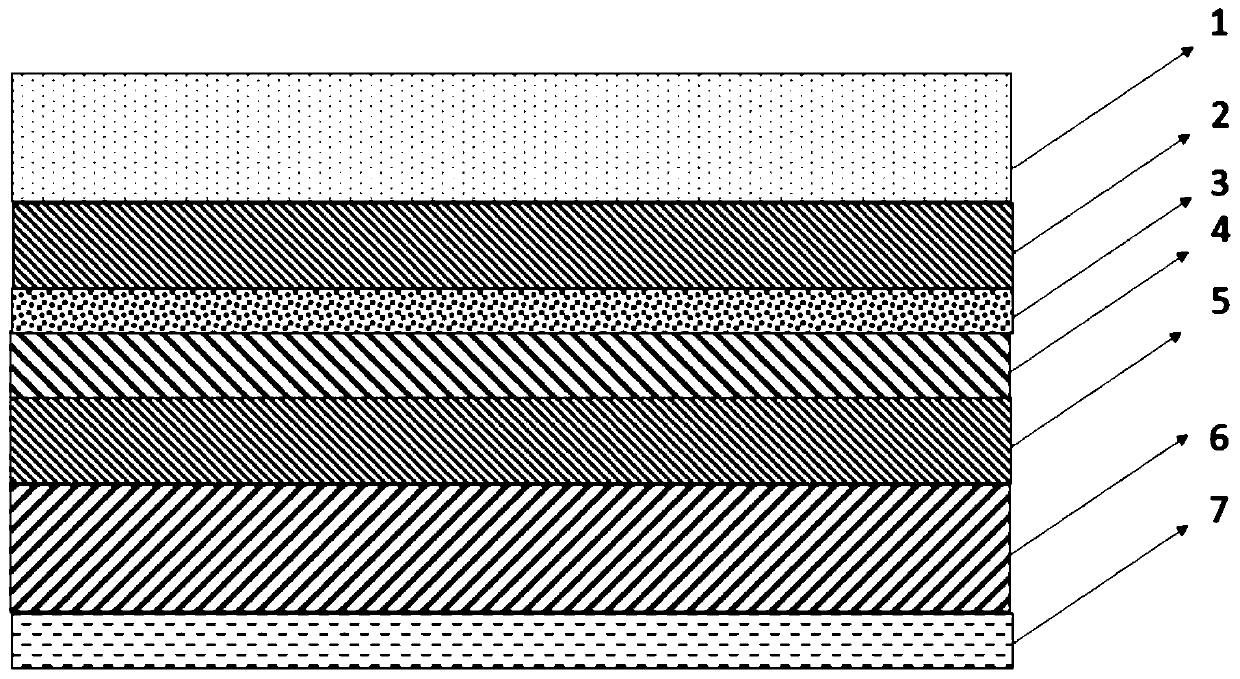

[0034] The preparation method of the battery back plate in this embodiment is as follows:

[0035] (1) Clean and dry the upper and lower sides of the high-barrier film substrate layer 4, and use a vacuum coating machine to vacuum evaporate the surface of the high-barrier film substrate layer 4 to form a reflective film layer 3 with a foggy silver appearance. By controlling the optical density unit OD value Adjust the thickness of the aluminum-coated layer so that the aluminum-coated layer has a specular reflection effect on sunlight, thereby increasing the reflectivity, which can be increased to more than 98%. At the same time, the production process of aluminized film is mature, cheap and high-quality, and has a high reflectivity to sunlight, which has a good cost-effective advantage.

[0036] (2) After mixing and stirring the main ingredients such as liquid silica gel, curing agent and anti-aging agent, the upper and lower sides of the composite film prepared in step (1) are...

Embodiment 2

[0042] The preparation method of the battery back plate in this embodiment is as follows:

[0043] (1) After degreasing, cleaning and drying the upper and lower surfaces of the high light-transmitting film layer, prepare a raised structure layer on one side of the high light-transmitting film layer by laser scribing or calendering. The cross-section of the raised structure layer is an isosceles triangle, The apex angle of this triangle is 138°.

[0044](3) Add the polymer resin particles into the organic solvent, stir at a high speed of 2000 rpm, and then add one or more of the thermally conductive fillers BN, graphite powder, SiC, etc., together with the tackifying resin, plasticizer and anti- The aging agent and the like are added to the above mixed resin solution, stirred evenly at a high speed, and then defoamed to prepare a thermally conductive adhesive mixture.

[0045] (3) Using the thermally conductive adhesive mixture prepared in step (2), apply the thermally conduct...

Embodiment 3

[0050] The preparation method of the battery back plate in this embodiment is as follows:

[0051] (1) Vacuum deposition on the surface of the metal film barrier layer by a vacuum coating machine to form a reflective film layer with a foggy silver appearance, and adjust the thickness of the aluminum-coated layer by controlling the optical density unit OD value, so that the aluminum-coated layer has a mirror reflection effect on sunlight , so as to improve the reflectivity, the reflectivity can be increased to more than 98%. At the same time, the production process of aluminized film is mature, cheap and high-quality, and has a high reflectivity to sunlight, which has a good cost-effective advantage.

[0052] (2) Stir and mix polyurethane resin, silane coupling agent, light stabilizer and antioxidant, etc., coat the surface of the aluminized layer prepared in step 1, and form a reflective film protective layer after drying.

[0053] (3) Add the polymer resin particles into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water vapor transmission rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com