Low-temperature rapid preparing method for high-density nanocrystalline tungsten copper base block composite materials

A composite material and nanocrystalline technology, which is applied in the field of refractory metals and powder metallurgy, can solve problems such as no reports of tungsten-copper-based bulk composite materials, and achieve a wide range of applications, improved hardness and elastic modulus, and high wear resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

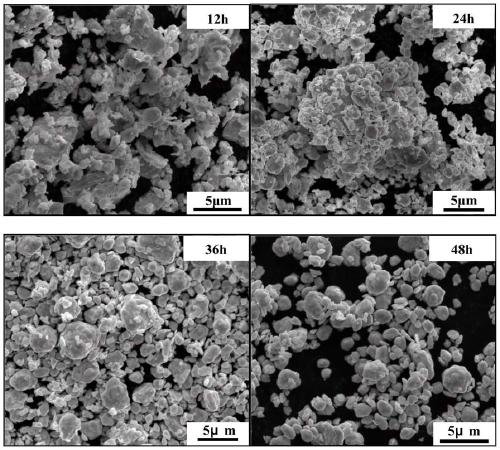

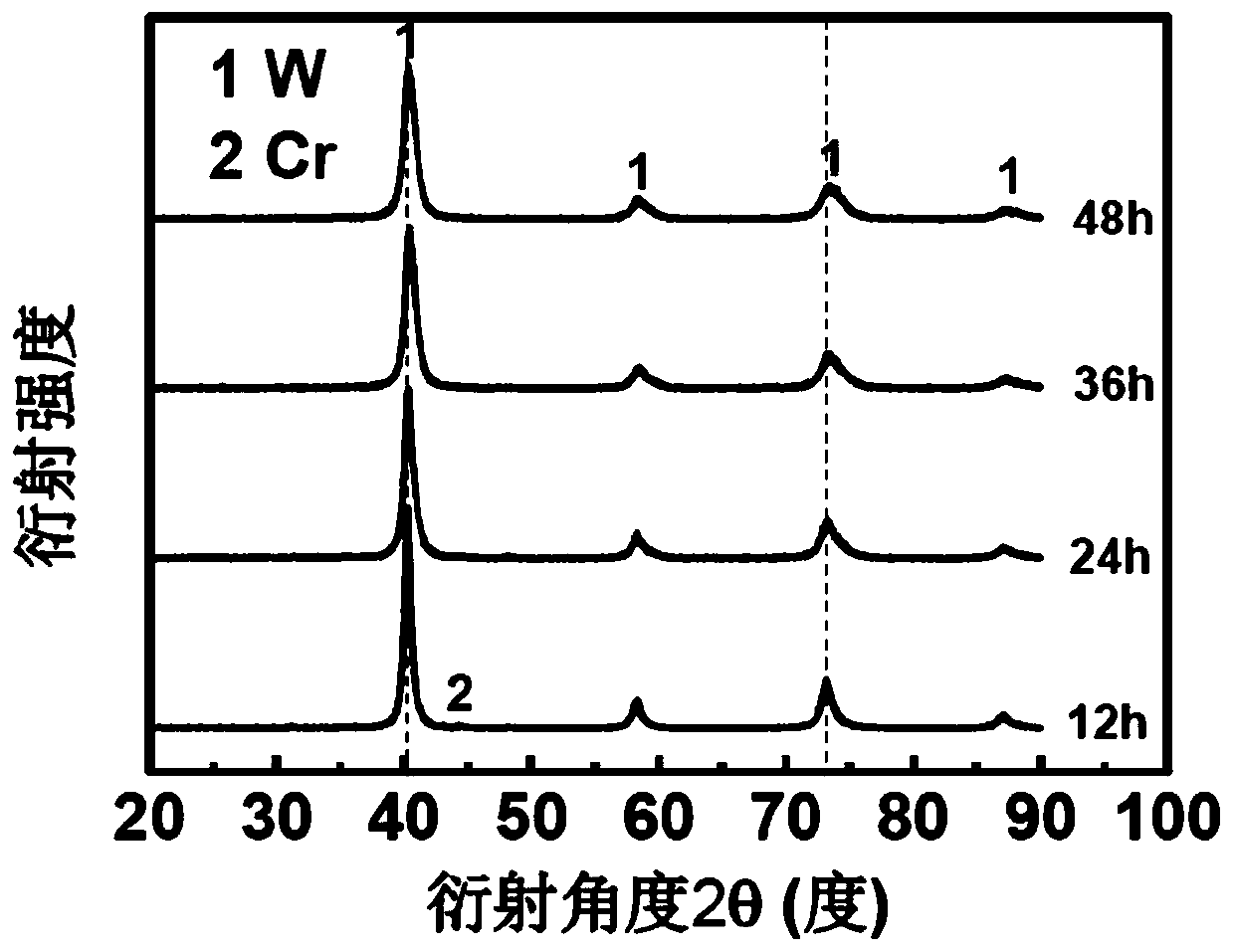

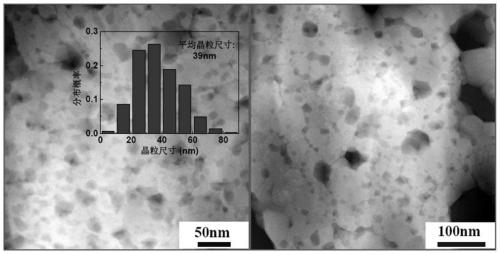

Embodiment 1

[0021] Weigh 28.50g of tungsten powder, 1.50g of chromium powder and 0.378g of zirconium carbide powder, the mass ratio of cemented carbide grinding ball to powder is 20:1, the inert gas argon is used as the protective gas, the speed of the planetary ball mill is 550r / min, and the ball mill Carry out in stages, grind for 90 minutes and stop for 30 minutes, scrape the powder once every 12 hours, add 7.59g of copper powder after ball milling for 48 hours, the ball-to-material ratio is 5:1, the speed is 120r / min, add absolute ethanol to wet mill for 9 hours and mix well. After drying the above-mentioned ball-milled powder for 12 hours, weigh 10 g and put it into a graphite mold, and then complete the mold loading process in a discharge plasma sintering furnace after cold pressing with a pressure of 15 MPa; Under the condition that the vacuum degree in the sintering chamber is 8Pa, start to pass the current, and the temperature rise rate is 100°C / min. At the same time, the sinterin...

Embodiment 2

[0023] Weigh 28.50g of tungsten powder, 1.50g of chromium powder and 0.337g of zirconium carbide powder, the mass ratio of cemented carbide grinding ball to powder is 25:1, the inert gas argon is used as the protective gas, the speed of the planetary ball mill is 500r / min, and the ball mill Carry out in stages, grind for 80 minutes and stop for 20 minutes, scrape the powder once every 10 hours, add 3.371g of copper powder after ball milling for 60 hours, the ball-to-material ratio is 8:1, the speed is 150r / min, add absolute ethanol to wet mill for 6 hours and mix well. After drying the above-mentioned ball-milled powder for 10 hours, weigh 15g and put it into a graphite mold, and then complete the molding process in a discharge plasma sintering furnace after cold pressing with a pressure of 20MPa; Under the condition that the vacuum degree in the sintering chamber is 10Pa, start to pass the current, the temperature rise rate is 120°C / min, increase the sintering pressure at the ...

Embodiment 3

[0025] Weigh 28.50g of tungsten powder, 1.50g of chromium powder and 0.508g of zirconium carbide powder, the mass ratio of cemented carbide grinding ball to powder is 15:1, the inert gas argon is used as the protective gas, the speed of the planetary ball mill is 400r / min, and the ball mill Carry out in stages, grind for 60 minutes and stop for 15 minutes, scrape the powder once every 15 hours, add 20.339g of copper powder after ball milling for 78 hours, the ball-to-material ratio is 3:1, the speed is 100r / min, add absolute ethanol to wet mill for 12 hours and mix well. After drying the above-mentioned ball-milled powder for 15 hours, weigh 20g and put it into a graphite mold, and then complete the molding process in a discharge plasma sintering furnace after cold pressing with a pressure of 10MPa; Under the condition that the vacuum degree in the sintering chamber is 6Pa, start to pass the current, the temperature rise rate is 80°C / min, increase the sintering pressure at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com