Preparation method of modified sulfur coated with two-component film forming agent

A technology of film-forming agent and film agent, which is applied in the field of chemical products, can solve the problems of low purity of insoluble sulfur products, is in the laboratory stage, and has not yet been industrialized, and achieves low modification cost, improved processing safety performance, and coating The effect of high modification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

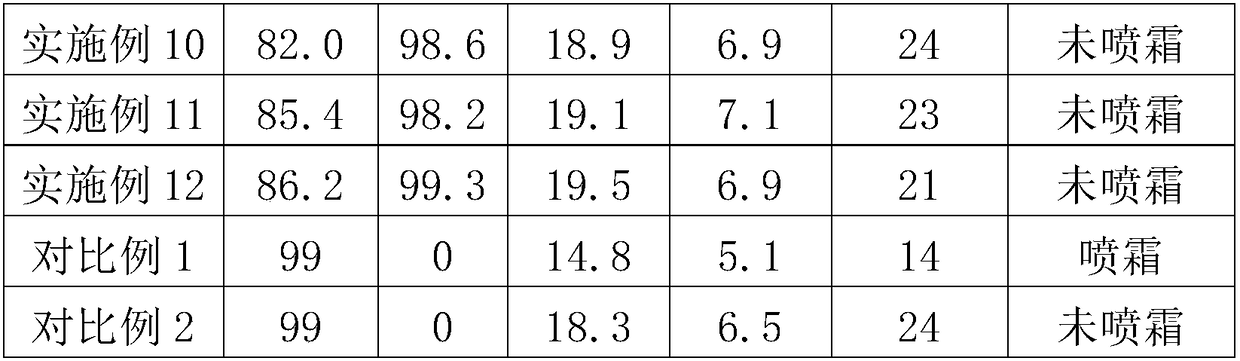

Examples

Embodiment 1

[0042]4kg of alkyd resin with a solid content of 20%, 4kg of amino resin with a solid content of 5%, and 2kg of m-phenylenediamine m-PDA MPD with a solid content of 10% were added to the stirring tank through a metering tank, and 5kg of solid content was 10%. % silica powder suspension is added into a stirring tank and mixed evenly for use. Add 10kg of sulfur powder to the mixer in advance, and then add the above mixed suspoemulsion to the sulfur powder according to the required proportions and mix evenly. The above materials were mixed by a kneading mixer for 10 minutes, and then rolled 3 times by a two-roller roller. mm; after each crushing, the distance between the axes is adjusted to 22mm for the first level, 19mm for the 2nd level, and 15mm for the 3rd level. After dispersing, the mixed material is granulated by a swing granulator, and the wet material is sent to a fluidized bed dryer for drying. The drying temperature is 120 ° C. The dried product is crushed by a hammer...

Embodiment 2

[0044] Add 1kg of acrylic resin with a solid content of 70% and 1kg of amino resin with a solid content of 70% into the stirring tank through a metering tank, and add 4kg of silica suspension with a solid content of 50% into the stirring tank and mix evenly for use. Add 10kg of sulfur powder to the mixer in advance, and then add the above mixed suspoemulsion to the sulfur powder according to the required proportions and mix evenly. The above materials were mixed by a coulter mixer for 30 minutes, and rolled for 5 times by a two-roller roller. , the spacing between the 4th grade rollers is 0.8mm, and the 5th grade roller spacing is 0.5mm; after each rolling, the shaft spacing is adjusted to 20mm, the 2nd grade is 16mm, and the 3rd The distance between the shafts of level 4 is 13mm, the distance between the axes of level 4 is 12mm, and the distance between the axes of level 5 is 10mm. After dispersing, the mixed material is granulated by a swing granulator, and the wet material...

Embodiment 3

[0046] 2.5kg of hydroxy acrylic resin with a solid content of 40% and 2.5kg of amino resin with a solid content of 40% were added to the stirring tank through a metering tank, and 5kg of the calcium carbonate suspension with a solid content of 20% was added to the stirring tank and mixed evenly for use. Add 10kg of sulfur powder to the mixer in advance, and then add the above mixed suspoemulsion to the sulfur powder according to the required proportions and mix evenly. The above materials were mixed by a ribbon mixer for 20 minutes, and then rolled 7 times by a three-roller roller. mm, the 4-level roll spacing is 0.8mm, the 5-level roll spacing is 0.5mm, the 6-level roll spacing is 0.2mm, and the 7-level roll spacing is 0.1mm; after each rolling, it is scattered once, and the shaft spacing is adjusted to 1 level in turn. The distance between the dispersing shafts is 20mm, the distance between the two-level dispersing axes is 16mm, the distance between the three-level dispersin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com