A batch preparation method of a suspended nanowire manipulator

A technology of nanowires and manipulators, which is applied in the field of batch preparation of suspended nanowire manipulators. It can solve problems such as obstacles to rapid analysis, shape changes, and fractures, and achieve good semiconductor characteristics, avoid parasitic effects, and avoid interference from environmental factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

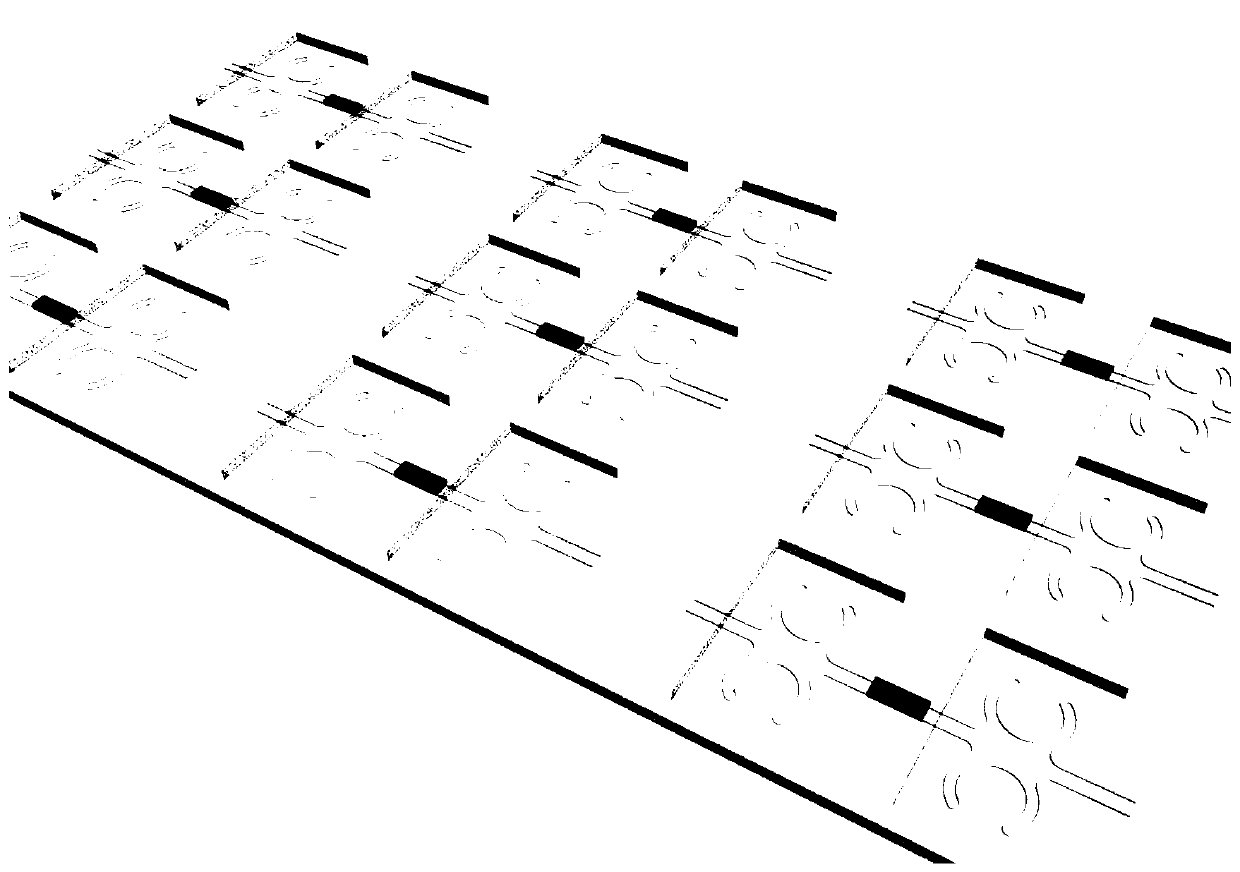

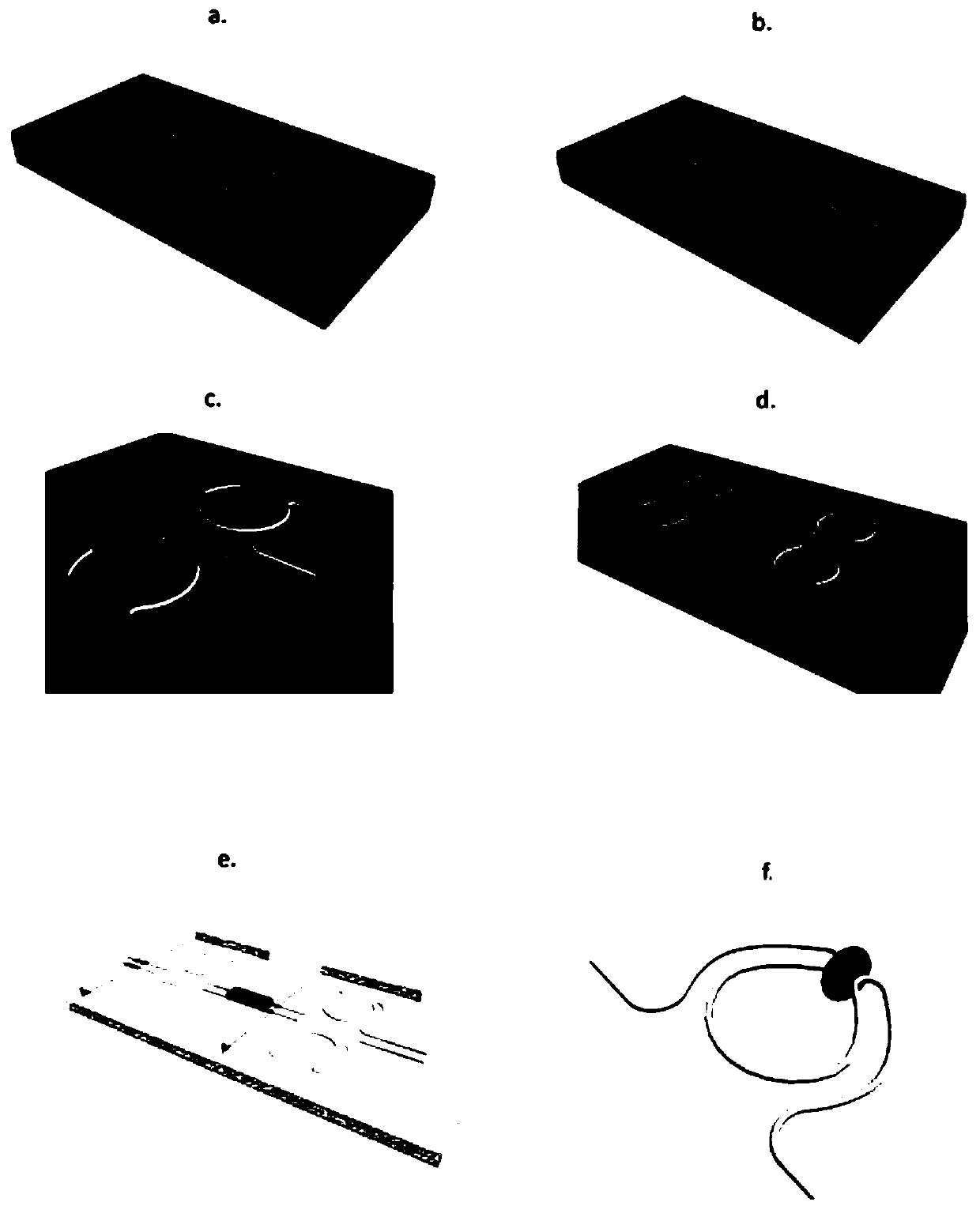

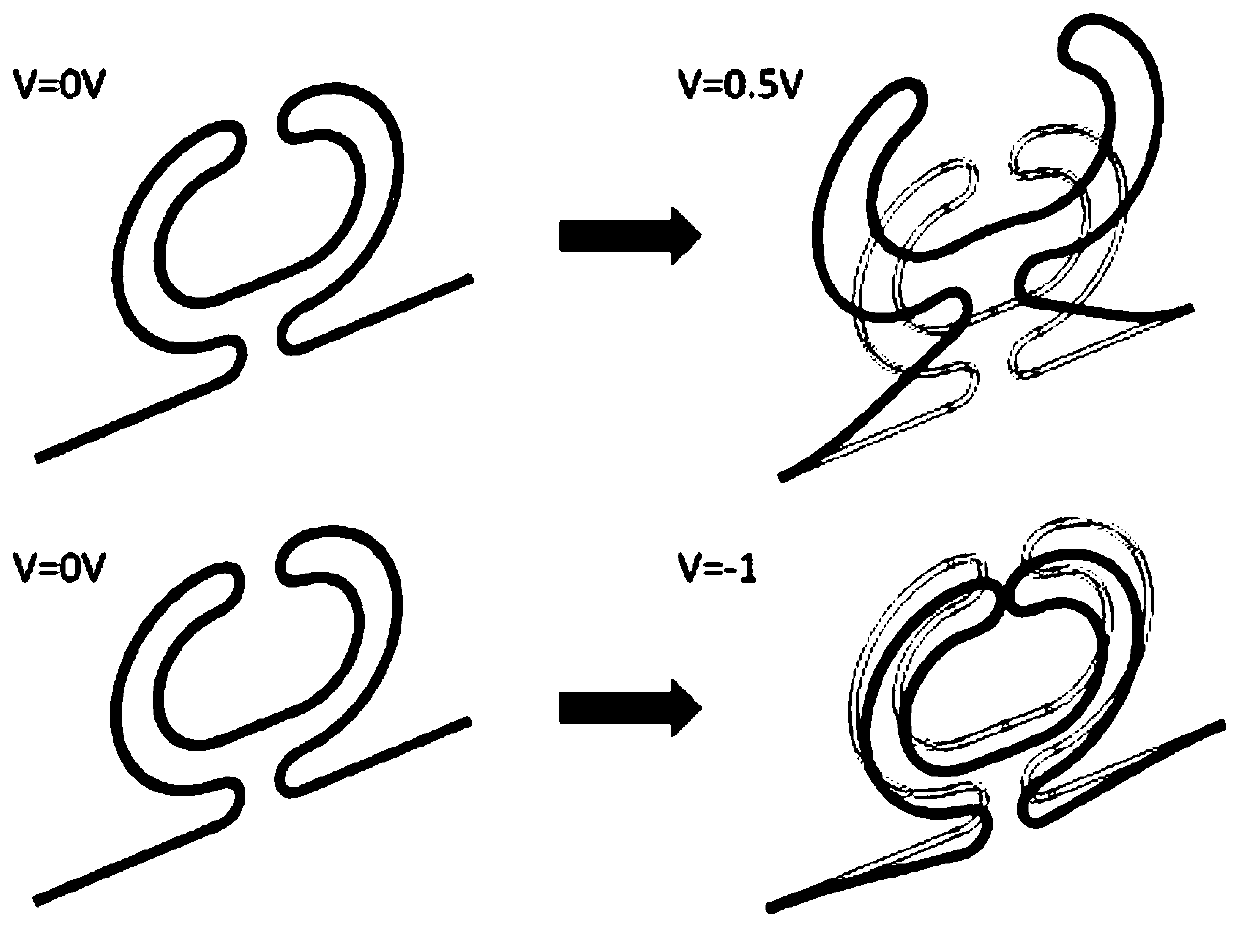

[0029] like figure 2 Shown is a method for preparing a batch of suspended nanowire manipulators, which uses colloidal materials to transfer the self-assembled nanomanipulator array to a flexible substrate to achieve the acquisition and detection of tiny objects. The preparation process may include the following steps:

[0030]1) Use crystalline silicon, glass or a metal film covered with a dielectric layer as the substrate, and deposit an amorphous dielectric layer (such as amorphous silicon oxide SiO2, silicon nitride SiNx, etc.) on it using one or more thin film deposition techniques Wait);

[0031] 2) Realize the required planar pattern by using photolithography technology, define the step position of the slope guiding channel, and etch the dielectric layer by using inductively coupled plasma (ICP) etching or reactive ion etching (RIE) technology; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com