Graphene preparation method

A technology of graphene and graphite, which is applied in the preparation of graphite materials, can solve the problems of deterioration of heat transfer efficiency, latent heat value and resistivity, and low heat transfer number of phase change materials, and achieve high solidity and high resistivity , high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one: the preparation of graphene (GE)

[0035] Add 5g of natural graphite powder (Graphite) into the mixed solution of sulfuric acid and nitric acid and stir evenly, then slowly add 55g of potassium chlorate. After the mixture was stirred at room temperature for 96 hours, 5% hydrochloric acid solution was repeatedly added and centrifuged until there was no sulfate ion in the solution, diluted with a large amount of deionized water and centrifuged until the pH value of the filtrate was neutral. The neutral solution was filtered through filter paper with a pore size of 0.5 μm, baked at 80° C. for 24 hrs, taken out, and ground with an agate mortar to obtain graphite oxide (GO) powder. Then put the prepared graphite oxide (GO) into the tubular high-temperature furnace, first vacuumize for 5 minutes, and then pass in argon for 30 minutes to prevent external air from entering and affecting the process. The heating rate is 60 ° C / Raise the temperature to 1100°C i...

Embodiment 2

[0036] Embodiment two: the preparation of exfoliated graphite flakes (xGnP) and modified exfoliated graphite flakes (M-xGnP)

[0037] Take 5g of expandable graphite and put it into a tube-type high-temperature furnace, first vacuumize for 5 minutes, and then pass in argon for 30 minutes to prevent external air from entering and affecting the process. ℃, keep the temperature for one hour, when the temperature is raised, continue to pass in 100 sccm of argon gas, and then pass in 20 sccm of hydrogen gas when the target temperature is reached, to increase the reduction effect, and thermally exfoliate the expandable graphite to obtain expanded graphite (EG). Add heat-treated expanded graphite (EG) to acetone solution, put it into an ultrasonic vibration tank for two hours to crush, and obtain exfoliated graphite nanoflakes (xGnP), and then prepare 400ml of sulfuric acid and nitric acid mixture with a ratio of 3:1, After being heated to a temperature of 80° C., 10 g of exfoliated g...

Embodiment 3

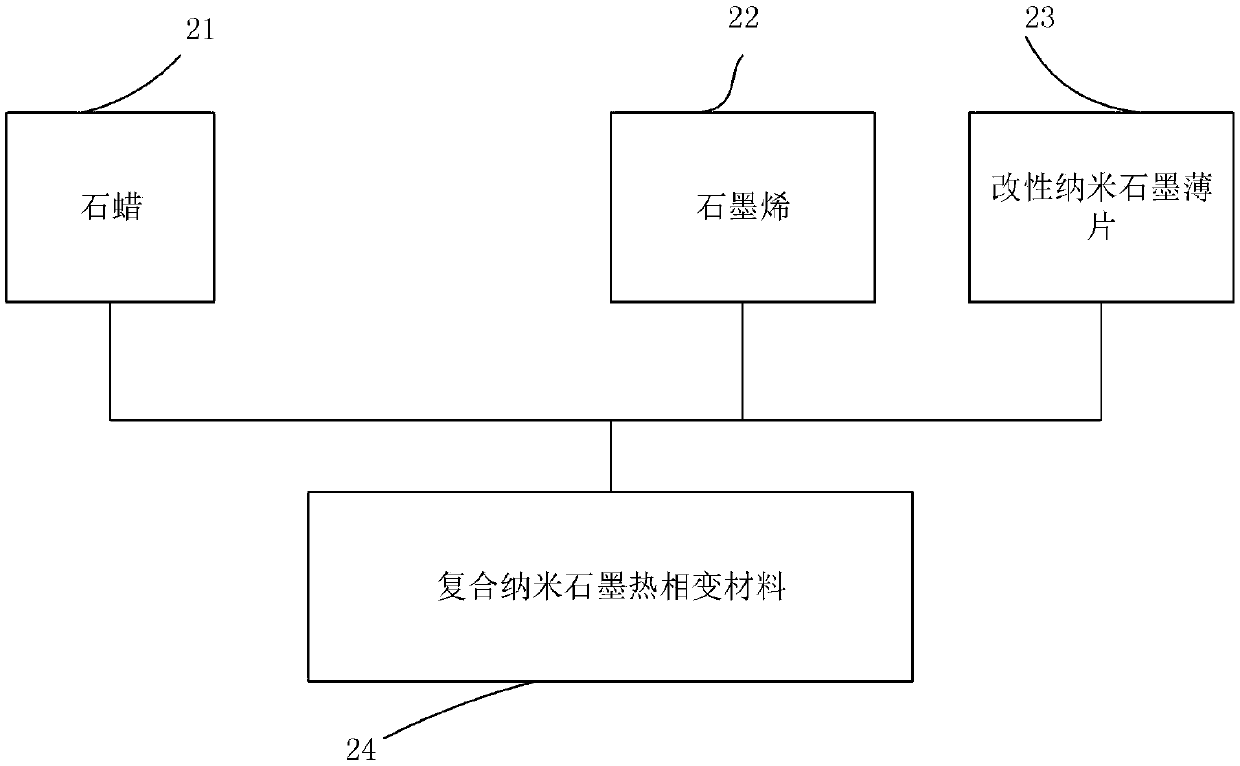

[0038] Example 3: Preparation of Composite Nanographite Thermal Phase Change Material

[0039] First take 60g of paraffin, set the temperature of the heating plate to 80°C, melt the paraffin, pour 200ml of toluene into the paraffin to dissolve. Slowly add composite nano-graphite material, graphite oxide (GO) / graphene (GE) / exfoliated nano-graphite flake (xGnP) three-phase composite material, perform ultrasonic vibration at 100W for 30 minutes and then shatter the aggregated composite nano-graphite material, And ensure that the nano-filler can be evenly dispersed, then continue to stir for one hour, pour the resulting mixture into a steel pan, and heat it to 130°C in a fume hood to evaporate the solvent, then pour it into a mold to form a mold and put it in an oven for 24hrs. The evaporated toluene solution was driven off. Among them, the composite nano-graphite material, graphite oxide (GO) / graphene (GE) / exfoliated nano-graphite flakes (xGnP) three-phase composite material wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com