Device and method for preparing high-purity titanium metal through molten salt electrolysis-high-temperature distilling

A molten salt electrolysis device and high-temperature distillation technology, applied in the field of high-purity titanium metal, can solve the problems of waste of high-purity titanium particles, secondary oxidation of high-purity titanium, and reduction of high-purity titanium yield, so as to achieve cost controllable, The effect of good product quality and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

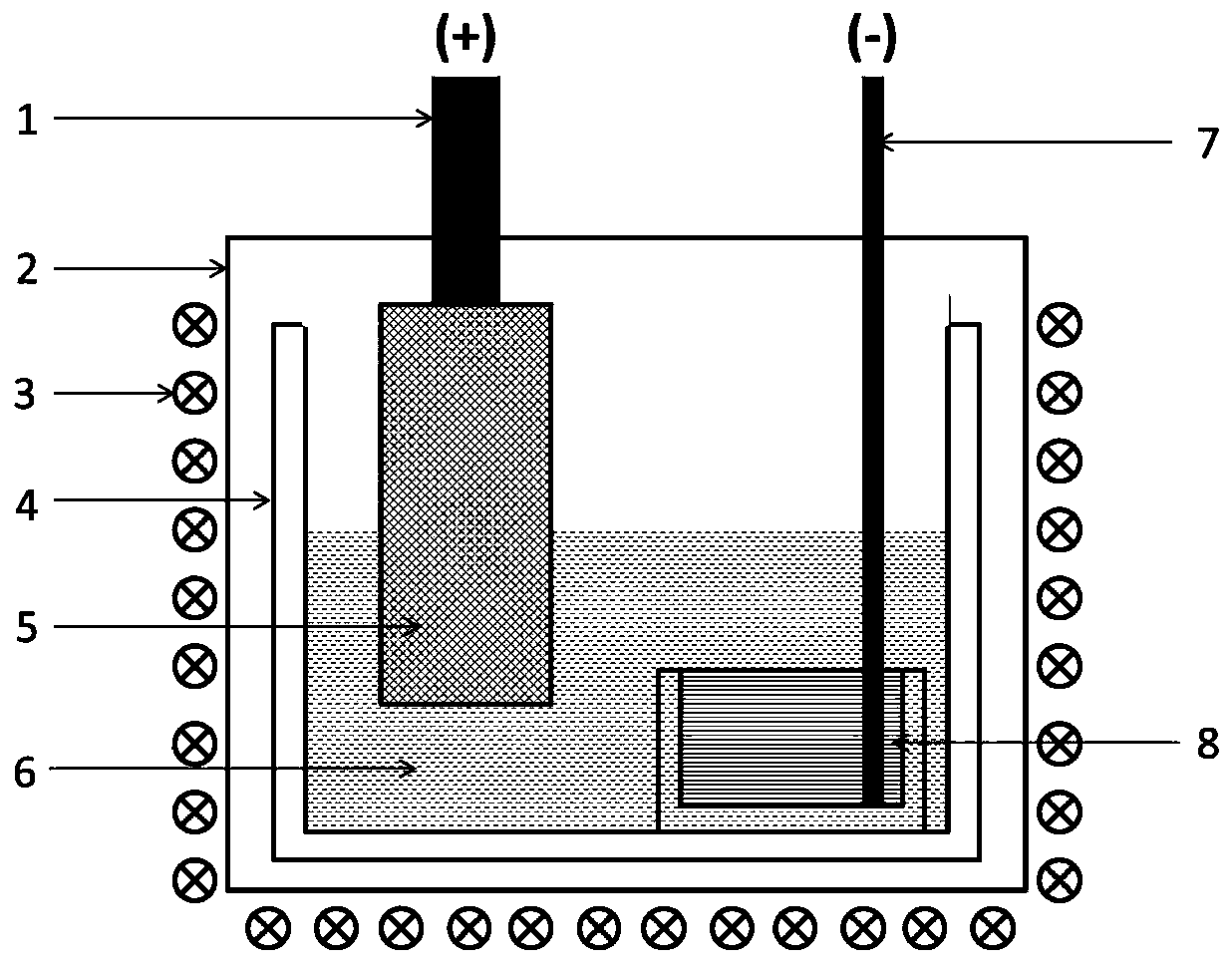

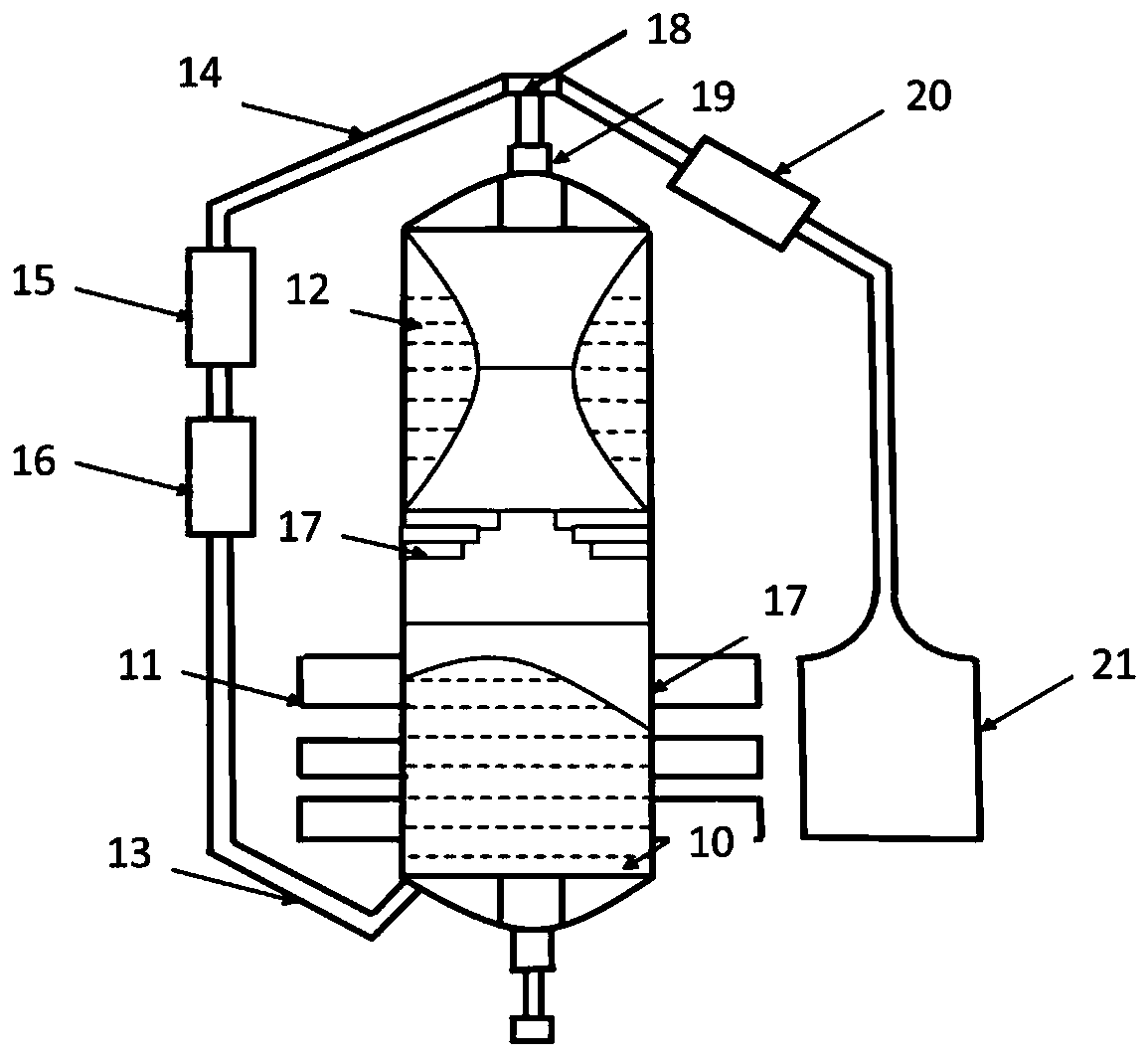

[0028] TiCl 3 And NaCl-KCl (molar ratio is 1:1) according to the mass ratio of 1:25 after uniform mixing, put into the electrolytic cell, the cathode is liquid metal bismuth, and the anode is a sponge Ti plate. The electrolysis is carried out after pre-melting at 800°C, and the electrolysis is stopped when the anode material is completely dissolved, and the electrolysis cathode product is Bi-Ti alloy. The cathode product was transferred to distillation equipment, and vacuum distillation was carried out in a distillation flask at 1580°C. The distillation product is dried and packaged to obtain high-purity titanium metal.

Embodiment 2

[0030] TiCl 2 and CaCl 2 -NaF (molar ratio 3:2) is evenly mixed according to the mass ratio of 1:30, and then loaded into the electrolytic cell, the cathode is liquid metal tin, and the anode is titanium carbon-oxygen solid solution. Electrolysis after pre-melting is carried out at 900°C, and the cathode product of electrolysis is Sn-Ti alloy. The cathode product was transferred to a distillation apparatus for vacuum distillation at 2280°C. The distillation product is dried and packaged to obtain high-purity titanium metal, and the obtained tin is further recycled.

Embodiment 3

[0032] TiCl 3 And KCl-NaF (molar ratio is 2:3) according to the mass ratio of 1:27 after mixing evenly, put it into the electrolytic cell, the cathode is liquid metal lead, and the anode is a sponge Ti plate. Electrolysis after pre-melting is carried out at 700°C, and the cathode product of electrolysis is Pb-Ti alloy. The cathode product was transferred to a distillation apparatus for vacuum distillation at 1780°C. The distillation product is dried and packaged to obtain high-purity titanium metal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com