High-dielectric-constant polyvinylidene fluoride (PVDF) as well as preparation method and application thereof

A technology with high dielectric constant and polyvinylidene fluoride, which is applied in the field of organic chemical materials, can solve problems such as the drop of the maximum service temperature, and achieve the effect of low crystallinity and excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

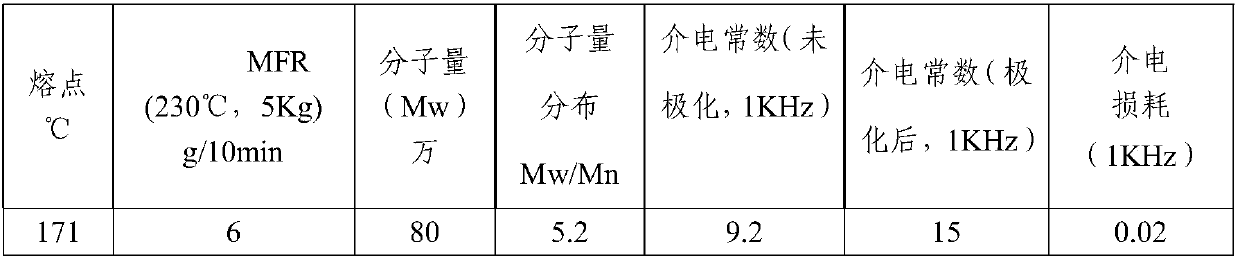

Embodiment 1

[0042] In a 50L stainless steel vertical reaction kettle, add 32L of deionized water, blow nitrogen and oxygen three times, evacuate until the oxygen content is less than or equal to 25ppm, add 40g of sodium acetate, 80g of fluorine-containing compound emulsifier, start stirring, the speed is 360rpm, and the temperature is raised to 130 ℃, add vinylidene fluoride monomer to 3.5MPa, after the system is stable, add 40g of ethyl acetate to the reactor through a metering pump, and then add 40g of dicumyl peroxide (DCP) into the reactor after a few minutes , start the polymerization reaction. At the same time, continue to add mixed monomers to keep the pressure of the reactor at 3.5 MPa until the solid content of the emulsion in the reactor reaches 30% to stop the reaction, recover the unreacted monomers, release the polymer emulsion, and freeze the obtained polymer in -35 ° C in brine. Coagulate and thaw to fully separate the material from water, wash with 60°C deionized water unt...

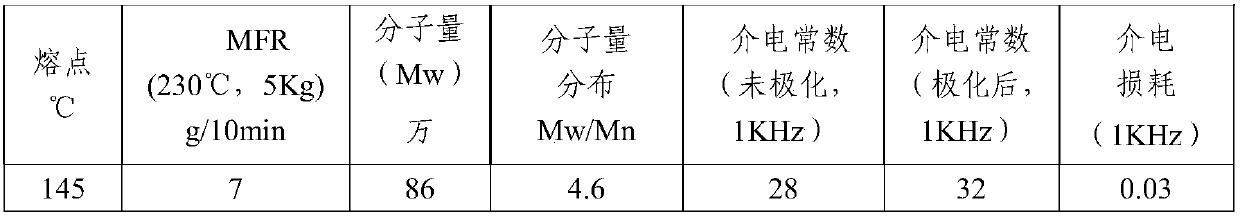

Embodiment 2

[0047] In a 50L stainless steel vertical reaction kettle, add 32L of deionized water, blow nitrogen and oxygen three times, evacuate until the oxygen content is less than or equal to 25ppm, add 40g of sodium acetate, 80g of fluorine-containing compound emulsifier, start stirring, the speed is 360rpm, and the temperature is raised to 130 ℃, add 85% vinylidene fluoride and 15% trifluoroethylene mixed monomer to 3.5MPa, after the system is stable, add 40g of isopropanol to the reaction kettle through a metering pump, and add 40g of dicumyl benzene after a few minutes Peroxide (DCP) is added to the reactor to start the polymerization reaction. At the same time, continue to add mixed monomers to keep the pressure of the reactor at 3.5 MPa until the solid content of the emulsion in the reactor reaches 30% to stop the reaction, recover the unreacted monomers, release the polymer emulsion, and freeze the obtained polymer in -35 ° C in brine. Coagulate and thaw to fully separate the ma...

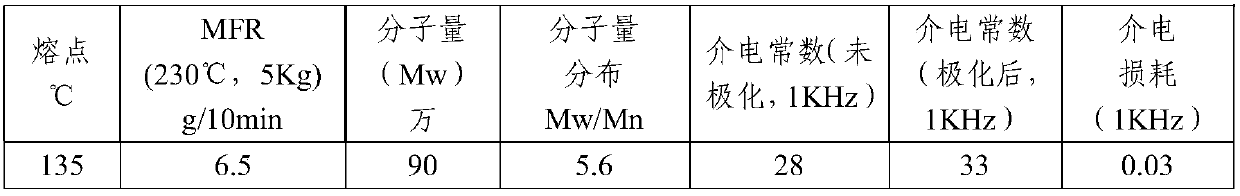

Embodiment 3

[0052] Repeat the steps described in Example 2, the only difference is that the mixed monomer ratio is 75% vinylidene fluoride, 15% trifluoroethylene and 10% chlorotrifluoroethylene.

[0053] The results are listed in Table 3.

[0054] table 3

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com