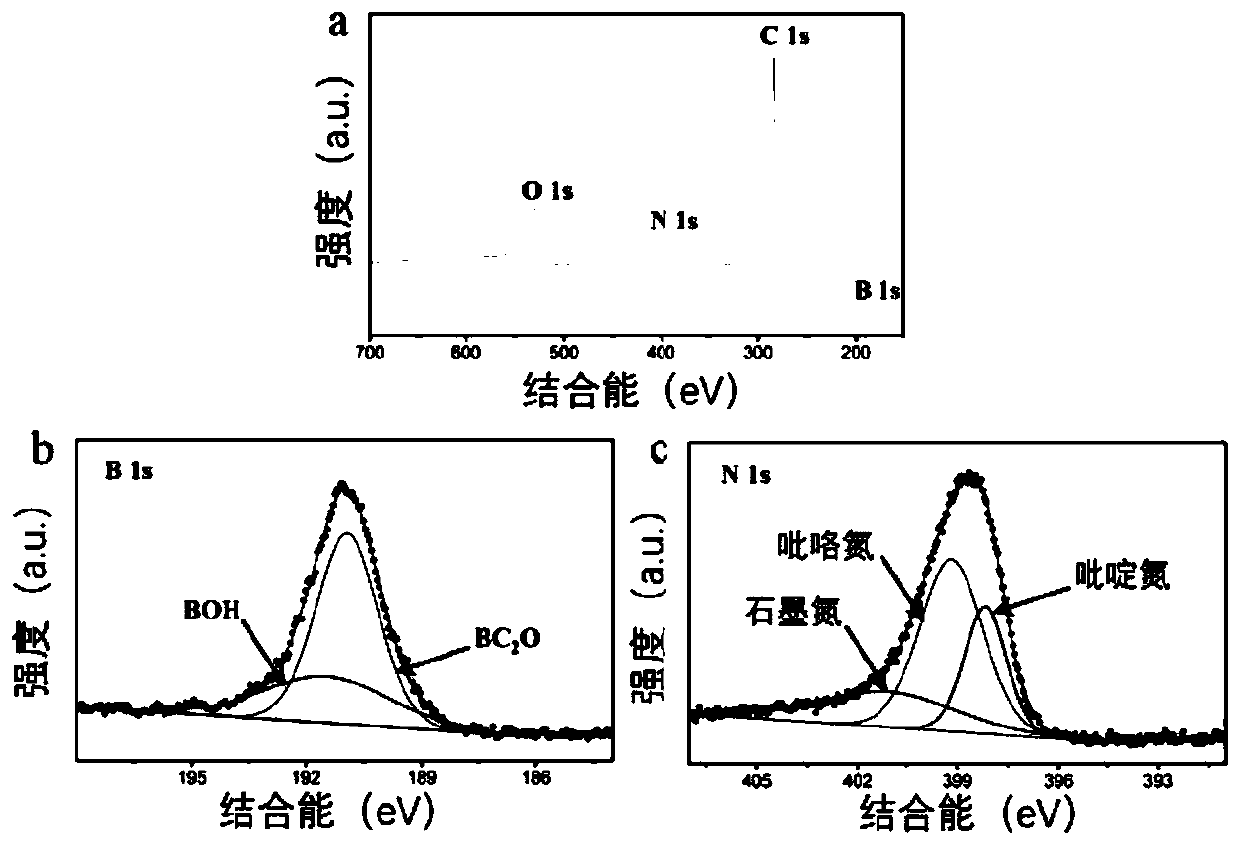

Boron-nitrogen co-doped carbon material and preparation method and application thereof

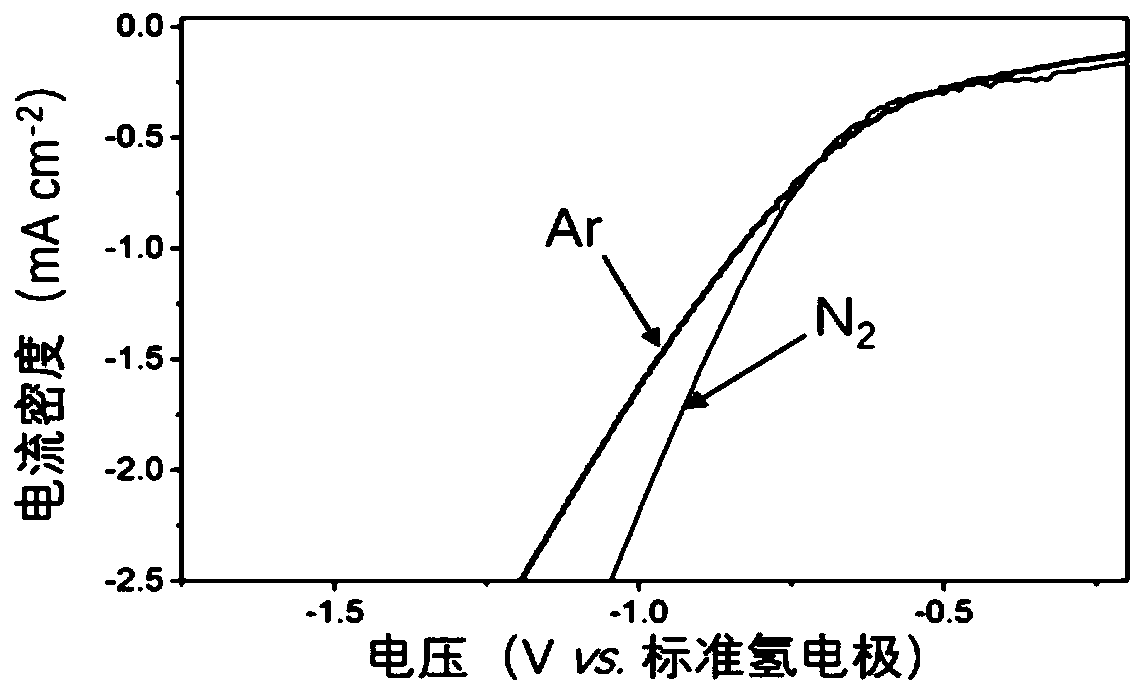

A carbon material and co-doping technology, applied in chemical instruments and methods, catalyst activation/preparation, electrodes, etc., can solve the problems of limited production Faraday effect, limited industrial application, and scarcity of precious metals, so as to improve reduction activity and selectivity The effect of sex, method efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

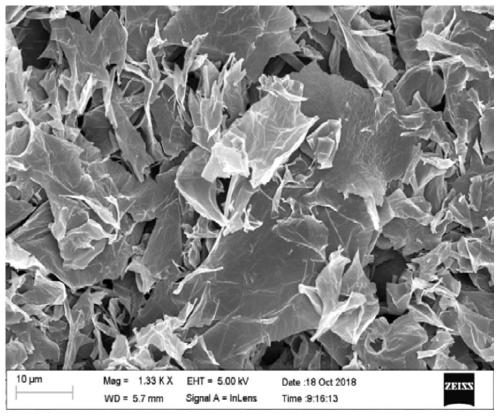

Embodiment 1

[0030] Boron nitride 0.2g and carbon material 0.1g are respectively placed in the center of two different temperature zones of a dual temperature zone tube furnace; the distance between the boron nitride and the carbon material is 15cm; Place 20mL of distilled water (intake end) at one end outside the zone, and the tube furnace heats up (the heating rate of the two temperature zones is 5°C / min). During the heating process, the distilled water outside the temperature zone is evaporated by the waste heat , a large amount of water vapor is generated; before the temperature is raised, the air in the tube is drawn out and supplemented with argon, which is used as a carrier gas to act on the whole experiment, and the argon flow rate is 50mL / min. Argon carries water vapor into the temperature zone where boron nitride is located for reaction. The temperature in the temperature zone of boron nitride is 1200°C. Water vapor reacts with boron nitride and keeps warm for 1 hour to obtain sma...

Embodiment 2

[0035] Boron nitride 0.8g and carbon material 0.1g are respectively placed in the center of two different temperature zones of a dual temperature zone tube furnace; the distance between the boron nitride and the carbon material is 15cm; Place 80mL of distilled water (intake end) at one end outside the zone, and the tube furnace heats up (the heating rate of the two temperature zones is 10°C / min). During the heating process, the distilled water outside the temperature zone is evaporated by the waste heat , a large amount of water vapor is generated; before the temperature is raised, the air in the tube is drawn out and supplemented with argon, which is used as a carrier gas to act on the entire experiment, and the argon flow rate is 100mL / min. Argon carries water vapor into the temperature zone where boron nitride is located for reaction. The temperature in the temperature zone of boron nitride is 800°C. Water vapor reacts with boron nitride and keeps warm for 3 hours to obtain ...

Embodiment 3

[0039]Place 0.8g of boron nitride and 0.1g of carbon material in the center of two different temperature zones of the dual temperature zone tube furnace; Carry out temperature rise (the temperature rise rate of the two temperature zones is 15°C / min). During the temperature rise process, the distilled water outside the temperature zone is evaporated by the waste heat of the air inlet temperature zone, producing a large amount of water vapor; In addition, argon was used as a carrier gas to act on the whole experiment, and the flow rate of argon was 200mL / min. Argon carries water vapor into the temperature zone where boron nitride is located for reaction. The temperature in the temperature zone of boron nitride is 1000°C. Water vapor reacts with boron nitride and keeps warm for 2 hours to obtain small precursor molecules; The air flow enters the high-temperature reaction zone of the carbon material. The temperature of the temperature zone where the carbon material is located is 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com