Method for regeneration treatment of industrial waster water treating water

A technology for industrial sewage and water treatment, applied in flotation water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low investment and poor treatment effect, and achieve low investment cost , Reduce chromaticity, good effect of air flotation separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

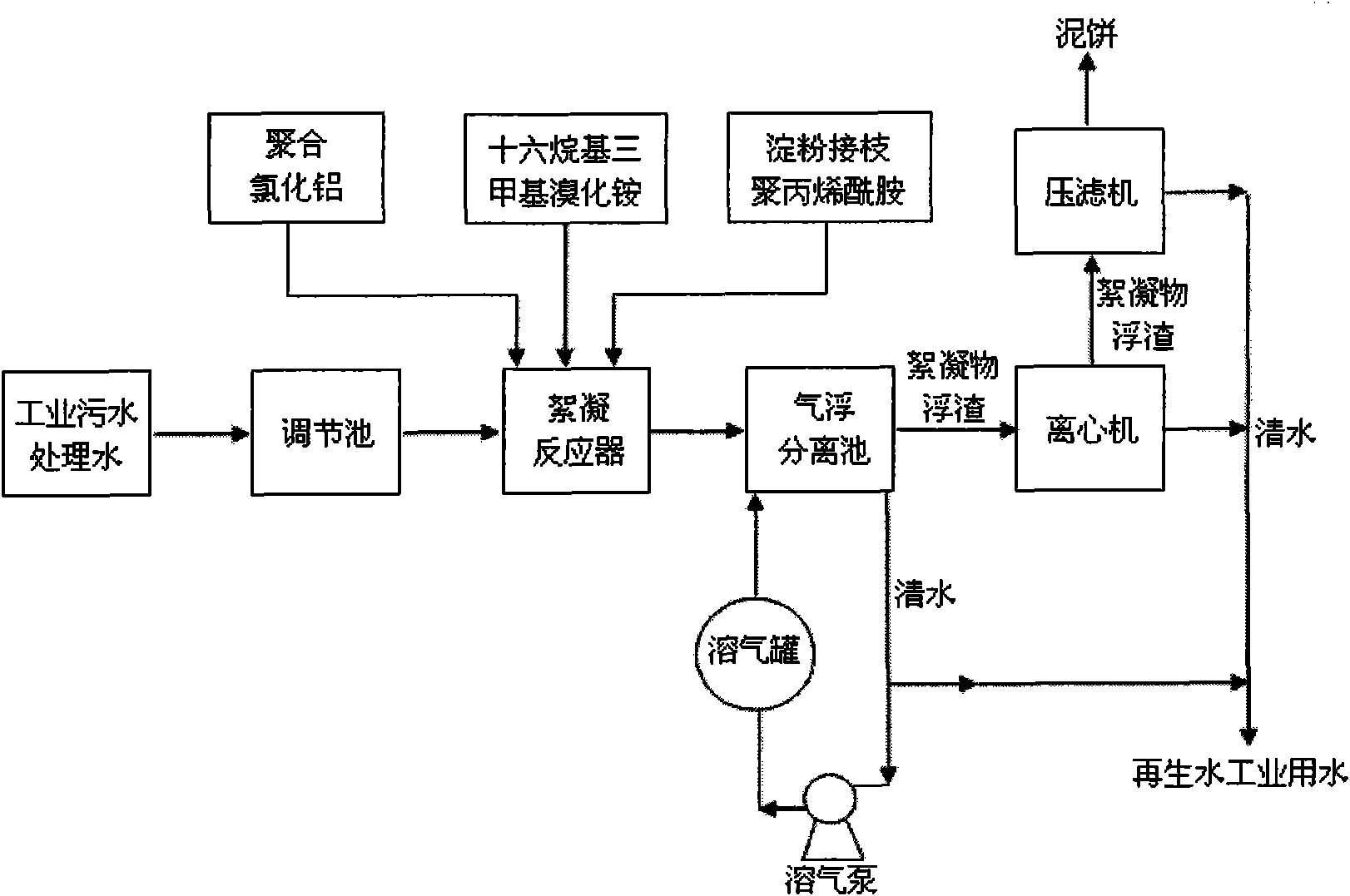

[0020] A method for recycling industrial sewage treatment water: the main water quality index of industrial sewage treatment water is: COD Cr It is 90~120mg / L, and the chromaticity is 500~700 degrees. The technological process for treating the industrial sewage treatment water is as follows: figure 1 Shown:

[0021] First, adjust the pH value of the industrial sewage treatment water entering the adjustment tank to 5-6; the industrial sewage treatment water after adjusting the pH value enters the flocculation reactor, and polyaluminum chloride, cetyltrimethylammonium bromide and starch Grafted polyacrylamide is added to the flocculation reactor at the same time, and stirred at 15-20°C for 2-5 minutes to carry out the flocculation decolorization reaction; the industrial sewage treatment water after the flocculation decolorization reaction enters the air flotation separation tank, and the flotation is removed by a slag scraper. The floc scum on the liquid surface of the air flo...

Embodiment 2

[0026] A method for recycling industrial sewage treatment water: the main water quality index of industrial sewage treatment water is: COD Cr It is 120-160mg / L, and the chromaticity is 700-900 degrees. The technological process for treating the industrial sewage treatment water is as follows: figure 1 Shown:

[0027] First, adjust the pH value of the industrial sewage treatment water entering the adjustment tank to 6-7; the industrial sewage treatment water after adjusting the pH value enters the flocculation reactor, and polyaluminum chloride, cetyltrimethylammonium bromide and starch Grafted polyacrylamide is added to the flocculation reactor at the same time, and stirred at 20-25°C for 5-8 minutes to carry out the flocculation and decolorization reaction; the industrial sewage treatment water after the flocculation and decolorization reaction enters the air flotation separation tank, and the flotation is removed by a slag scraper. The floc scum on the liquid surface of th...

Embodiment 3

[0032] A method for recycling industrial sewage treatment water: the main water quality index of industrial sewage treatment water is: COD Cr It is 160-200mg / L, and the chromaticity is 900-1100 degrees. The technological process for treating the industrial sewage treatment water is as follows: figure 1 Shown:

[0033] First, adjust the pH value of the industrial sewage treatment water entering the adjustment tank to 5-6; the industrial sewage treatment water after adjusting the pH value enters the flocculation reactor, and polyaluminum chloride, cetyltrimethylammonium bromide and starch Grafted polyacrylamide is added to the flocculation reactor at the same time, and stirred at 25-30°C for 8-10 minutes to carry out the flocculation decolorization reaction; the industrial sewage treatment water after the flocculation decolorization reaction enters the air flotation separation tank, and the flotation is removed by a slag scraper. The floc scum on the liquid surface of the air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chroma | aaaaa | aaaaa |

| Chroma | aaaaa | aaaaa |

| Chroma | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com