Synthetic method of methyl ethyl ketone peroxide with no three wastes produced

A technology of methyl ethyl ketone peroxide and a synthesis method, applied in the field of methyl ethyl ketone peroxide synthesis, can solve problems such as three wastes, and achieve the effects of solving the problems of three wastes, stable reaction process, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

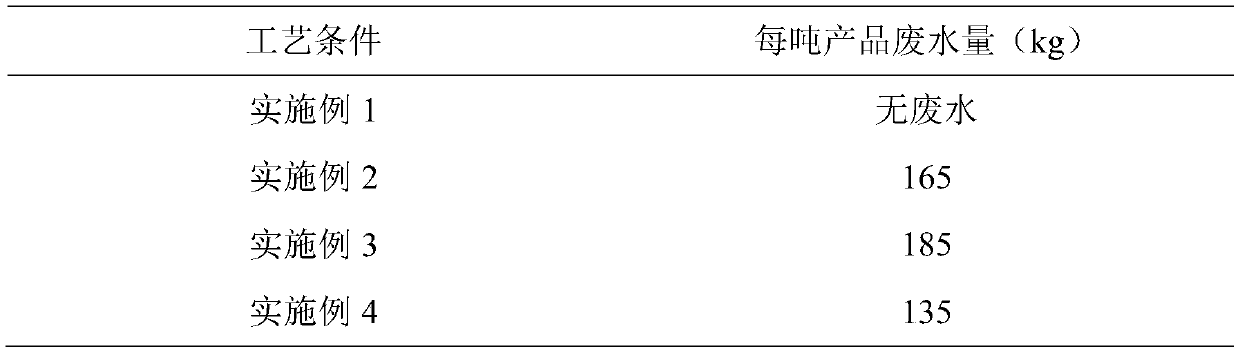

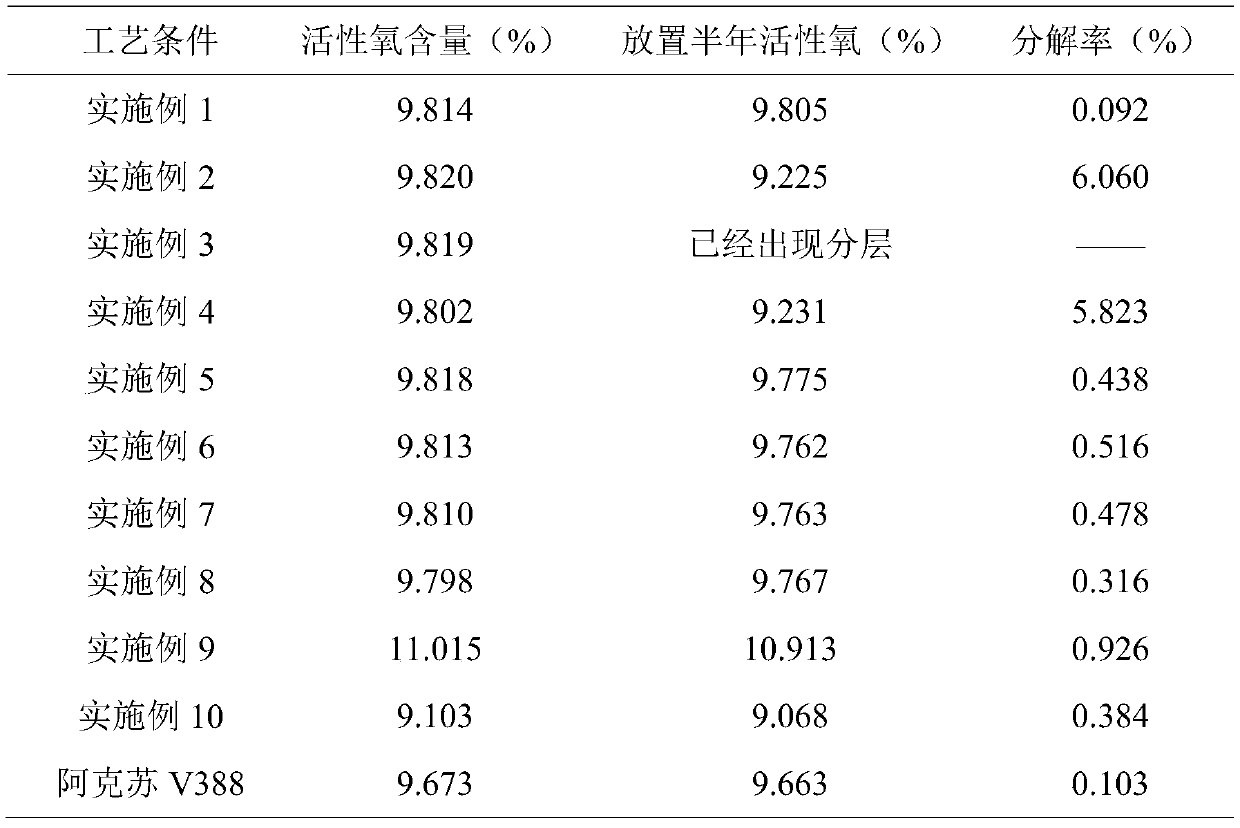

Examples

Embodiment 1

[0021] In a 250ml four-necked bottle equipped with stirring, a thermometer, and a dropping funnel, sequentially add 90g (1.323mol) of 50% hydrogen peroxide and 15.0g of 99.5% dimethyl phthalate. Under the condition of stirring, control the temperature of the reaction system at 20-22°C through an external constant temperature water bath, and then slowly add 50.5g (0.700mol) of methyl ethyl ketone to the system through the dropping funnel, and the dropping time is maintained at 2.0h After the dropwise addition, continue to stir and react at this temperature for 1.0h. After the reaction is completed, add 45g of ethylene glycol and 0.004g of product stabilizer to the system under stirring conditions, and continue stirring for 10 minutes until the stabilizer is completely Dissolved to obtain 200 g of the product with an active oxygen content of 9.81%.

Embodiment 2

[0023] In a 250ml four-necked bottle equipped with stirring, a thermometer, and a dropping funnel, sequentially add 15.0g of 99.5% dimethyl phthalate, 50.5g (0.700mol) of methyl ethyl ketone, complete the addition, start stirring, and Under stirring conditions, drop 0.3g of 60-65% nitric acid into the system, then pass through an external constant temperature water bath, control the temperature of the reaction system at 20-22°C, and then slowly add 90g (1.323 mol) 50% hydrogen peroxide, the dropping time is maintained at about 2.0h. After the dropping is completed, continue to stir and react at this temperature for 1.0h, then stop stirring, keep warm for 0.5h, and separate out about 33.0g of water. , start stirring again, under stirring condition, add ethylene glycol 50.0g, product stabilizer 0.004g to the system, continue to stir for 10 minutes, dissolve completely to stabilizer, obtain product amount 172.8g, active oxygen content 9.82%.

Embodiment 3

[0025] In a 250ml four-necked bottle equipped with stirring, a thermometer, and a dropping funnel, sequentially add 15.0g of 99.5% dimethyl phthalate, 50.5g (0.700mol) of methyl ethyl ketone, complete the addition, start stirring, and Under the condition of stirring, add 0.3g of 95-98% sulfuric acid dropwise, then through an external constant temperature water bath, control the temperature of the reaction system at 20-22°C, then slowly add 90g (1.323mol) of 50 % hydrogen peroxide, the dropping time is maintained at about 2.0h. After the dropping is completed, continue to stir and react at this temperature for 1.0h, then stop stirring, keep the temperature for 0.5h, until the system has clear layers and 37.0g of water is separated, start again Stir, under stirring condition, add ethylene glycol 54.0g, product stabilizer 0.004g to the system, continue to stir for 10 minutes, until stabilizer dissolves completely, obtain product 172.3g, active oxygen content 9.82%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com