Processing technology of a noise-absorbing ball valve and valve ball

A valve ball and ball valve technology, applied in the field of ball valve and valve ball processing technology, can solve the problems of low yield of valve ball, unfavorable diversion formation, cumbersome process and other problems, and achieve the effect of reducing production difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

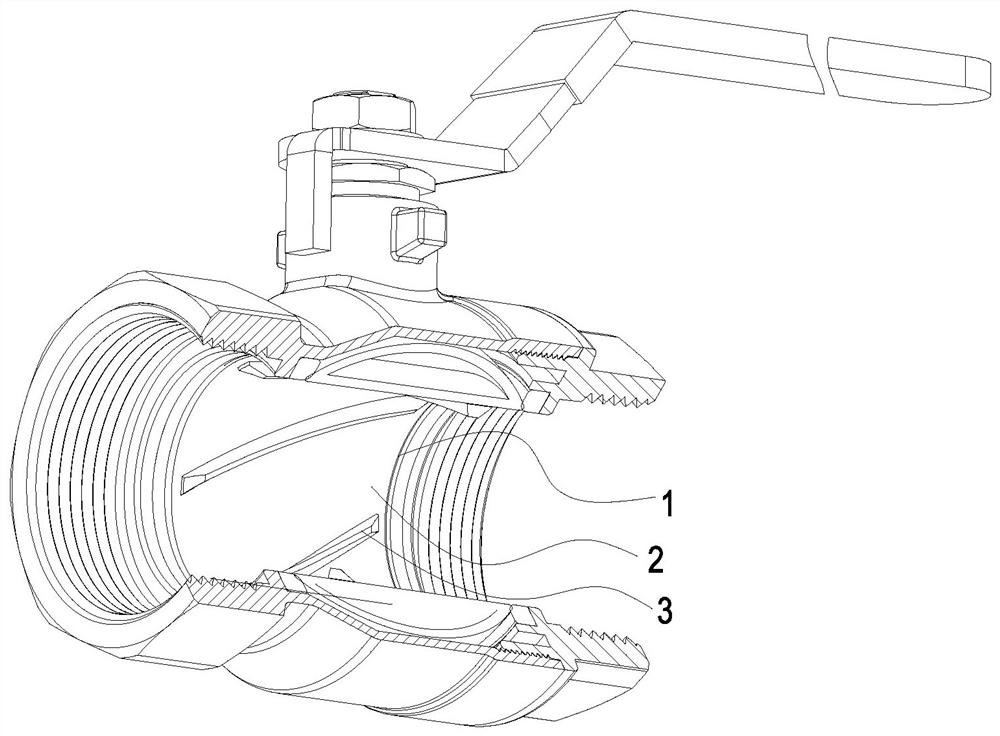

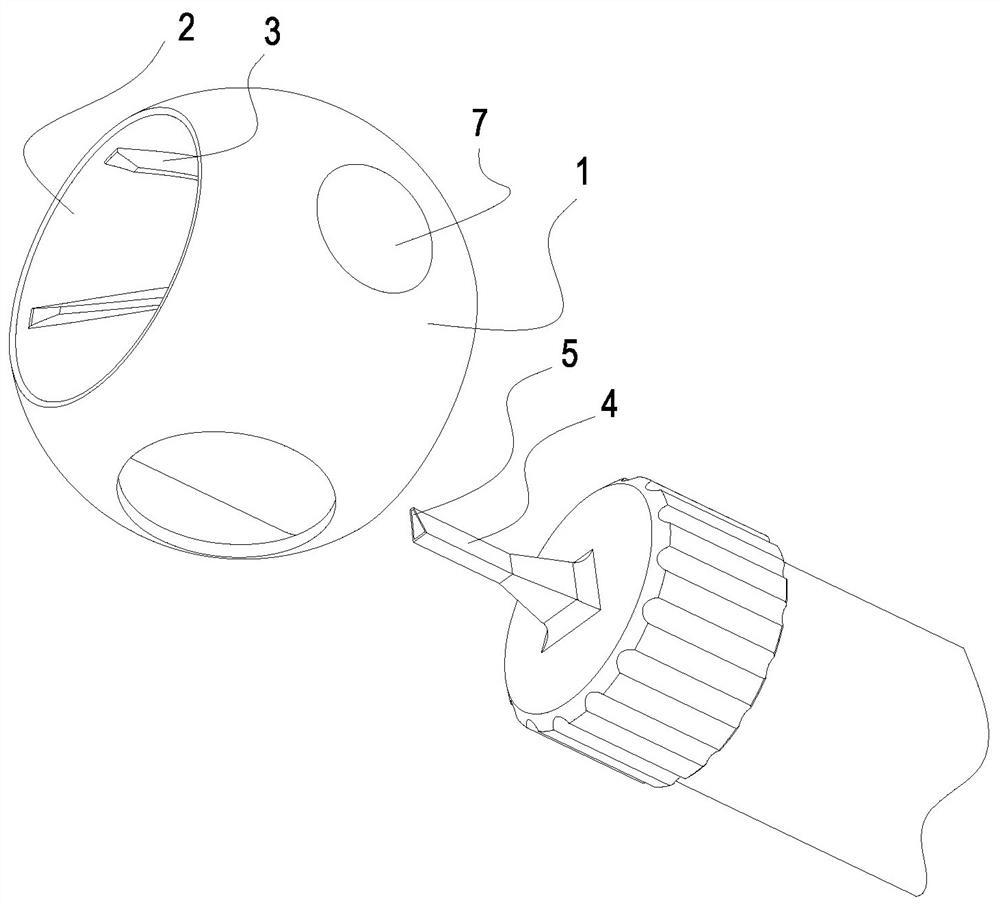

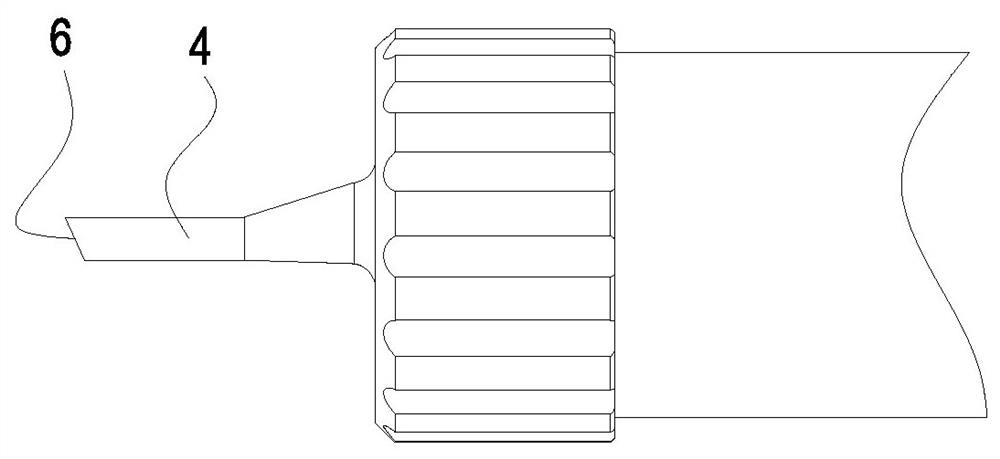

[0022] The valve ball and its processing processes of the present invention will be further described with reference to the drawings.

[0023] like figure 1 A muffler, including a valve ball 1, has a guide strap 3 in the valve ball 1 inner hole 2, and the angle of the guide band 3 and the centerline of the valve ball 1 is 3 ° to 50 °, the valve ball 1 is a metal material, and the fluid band 3 is a flexible non-metallic material, and the fluid band 3 is bonded to the valve ball 1 inner hole 2. The guide band 3 has six in the valve ball, according to the scorpion of the spherical specification and the pipe medium, the amount of the flow of flow can be adjusted, generally in one or more. The pipe medium can cause changes in the direction of the pipe medium during air or flow rate, and the flow of disorder and water flow impact are caused by pipe noise. Through the spherical caile 3 capable of combing the pipe medium, the pipe medium is rotationally flowing, less collision, thereby ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com