An environmentally friendly bio-oil recovery method

An environmentally friendly and biological technology, applied in the field of biological flooding, can solve the problems of high construction process requirements, difficult sewage treatment, low sweep efficiency, etc., and achieve the effect of improving activation effect, reducing harmful substances, and reducing cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Nutrient ingredient screening experiment and analysis experiment.

[0051] (1) Take an appropriate amount of crude oil from the oil field test area, and use glycerin, yeast extract, ethanol, sucrose, molasses, MgSO 4 , MgCl, KCl, K 2 SO 4 , NH4Cl, NaNO 3 , (NH 4 ) 2 HPO 4 、K 2 HPO 4 、Na 2 SO 4 , FeSO 4 , CaCl 2 , CaCO 3 , NaCl and Na 2 MoO 4 Select nutrients and cultivate them separately:

[0052] ①Add glycerin, yeast extract and ethanol to the crude oil, divide it into 2 parts, add sucrose or molasses to each part respectively, and culture on a shaker at 60°C and 200rpm for 10 days, measure the emulsification phenomenon and discharge of crude oil in different culture systems. The size of the oil circle and the concentration of the bacteria, compared and screened out the suitable ingredient to be molasses;

[0053] ② Add glycerin, yeast extract, ethanol and molasses to the crude oil, divide it into 2 parts, and add MgSO to each part respectively 4 Or Mg...

Embodiment 2

[0064] Strain acquisition.

[0065] (1) Take an appropriate amount of reservoir formation water and insert it into the enrichment medium, which is an inorganic salt medium: (NH 4 ) 2 SO 4 4.5g / L, starch 2.0g / L, Na 2 HPO 4 2.0g / L, MgSO 4 ·7H 2 0.5g / L, NaCl1.5g / L, FeCl 2 0.5g / L, yeast powder 0.3g / L, asphalt 2.0g / L, liquid paraffin 5.0g / L, pH 7.2-7.5, sterilized at 121°C, cultured on a shaker at 60°C at 200rpm for 15-20 days.

[0066] (2) Gradually dilute the enriched culture solution in step (1), and evenly spread the bacterial solutions with dilution factors of 104 and 105 on the LB plate medium. Cultivate at 60°C for 1 to 2 days, select the cultured colonies, transfer them to liquid LB medium for expansion, insert the expanded seeds into the above medium for 20 days, and select single bacteria with the ability to emulsify liquid paraffin save.

[0067] Pick the single colonies screened by the above method and inoculate them in the crude oil fermentation medium (waste ...

Embodiment 3

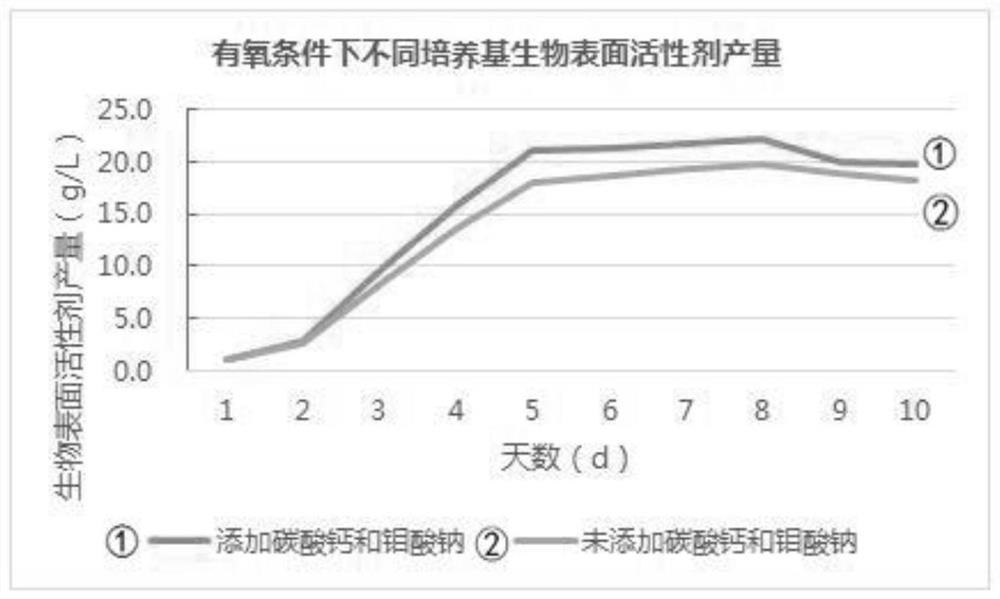

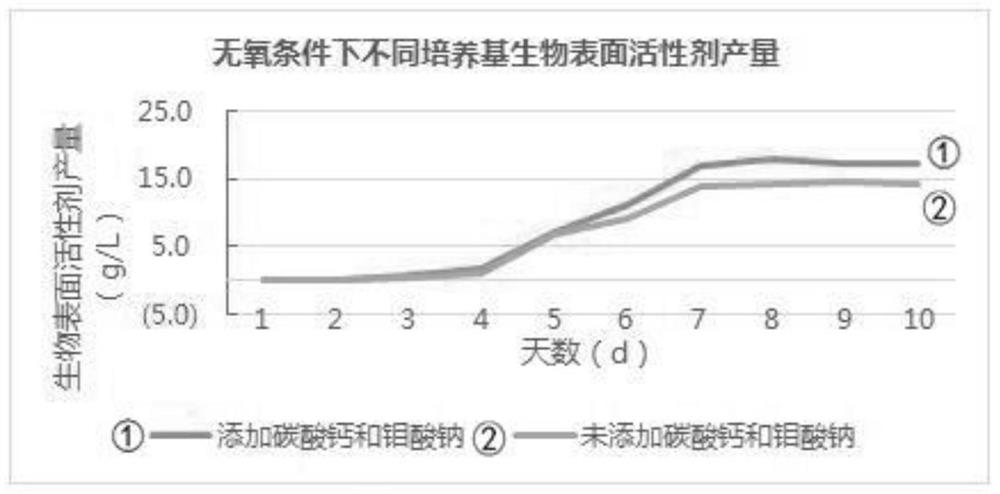

[0072] Production of bioactives and determination of their capacity.

[0073] (1) Inoculate CGMCC No.14770 strains in LB liquid medium with 0.5% crude oil, culture at 62°C 200r / min for 24 hours, then inoculate the bacteria in 1L of different crude oil medium, 62°C 200r / min Carry out aerobic and anaerobic shaker culture for 10 days; medium 1 includes crude oil 10g / L, molasses 2 / L, NaNO 3 2g / L, yeast extract 1g / L; K 2 HPO 4 1.2g / L, MgSO 4 0.5g / L, KCl0.5g / L, CaCO 3 0.02g / L,Na 2 MoO 4 0.01g / L, ethanol 0.01%, FeSO 4 0.01-0.05g / L, pH7.0~8.0, medium 2 includes crude oil 8g / L, molasses 2 / L, NaNO 3 2g / L, yeast extract 1g / L; K 2 HPO 4 1.2g / L, MgSO 4 0.5g / L, KCl0.5g / L, ethanol 0.01%, FeSO 4 0.01-0.05g / L, pH7.0-8.0. After the cultivation was completed, the fermentation broth was taken out and heated in a water bath at 60°C for 10 minutes, centrifuged at 10,000 g for 20 minutes to remove the bacteria, and the supernatant of the fermentation broth was taken, and after extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com